A peak-staggered design method for crank-triangular linkage-toggle linkage

A technology of triangular connecting rod and design method, which is applied in the direction of mechanical equipment, forging machine driving device, transmission device, etc. It can solve problems such as analysis and optimization relying on computer simulation, difficulty in finding the global optimal solution, and difficulty in accurate analysis , to achieve the effect of reducing the drive motor capacity, improving the motion characteristics, and increasing the average speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

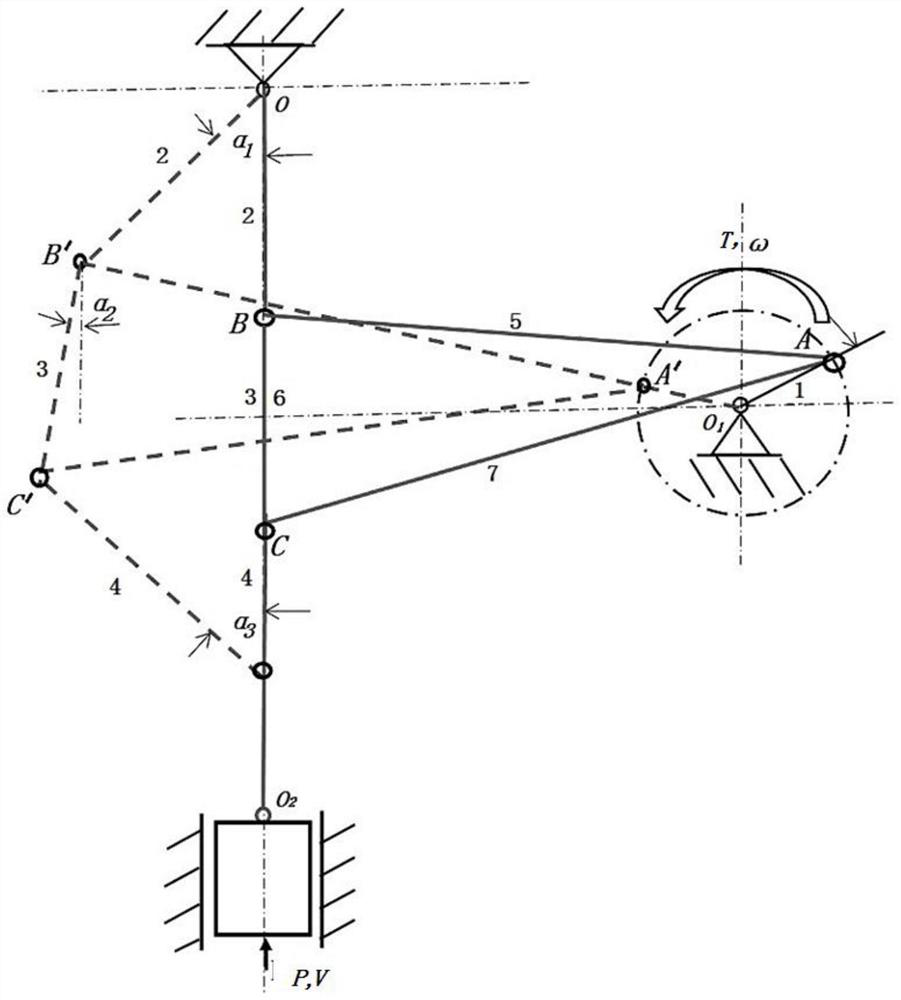

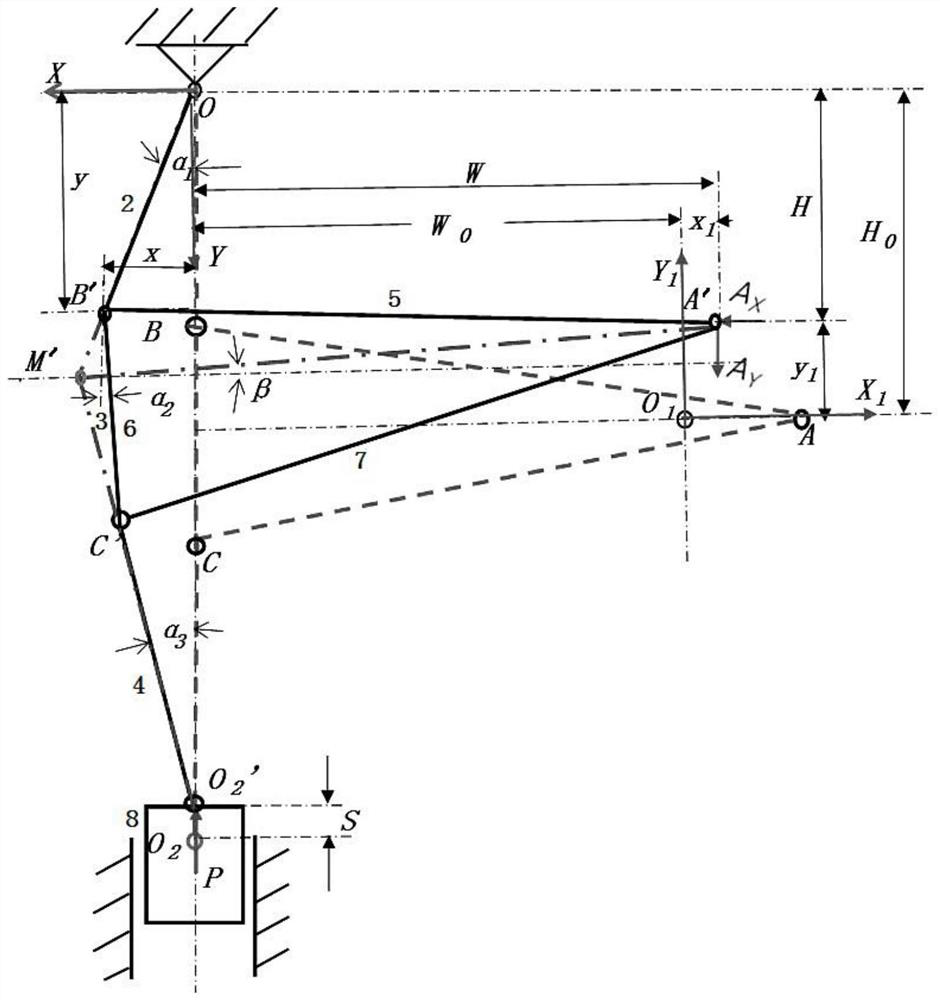

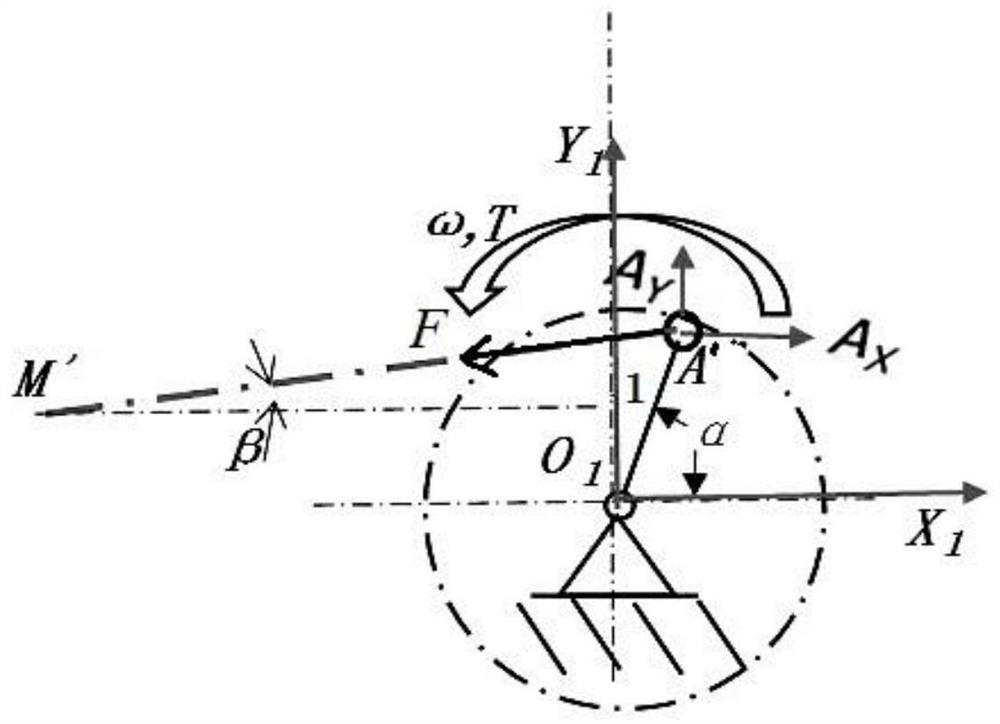

[0048] like Figure 1 to Figure 6 Shown is the staggered peak design method of the crank-triangular linkage-toggle linkage mechanism of the present invention, the crank-triangular linkage-toggle linkage includes sequentially articulated crank 1, triangular linkage ΔABC and toggle, and the toggle includes sequential The first toggle 2, the second toggle 3 and the third toggle 4 which are hingedly arranged, the triangular connecting rod comprises the first connecting rod 5, the second connecting rod 6 and the third connecting rod 7 which are sequentially hinged, and the triangular connecting rod The apex of the bar is hinged with the crank 1, the second connecting rod 6 of the bottom edge of the triangular connecting rod is integrated with the second toggle lever 3, and one end of the third toggle lever 4 is connected with a slide block 8. In this embodiment, the center of rotation of the crank is O 1 , the connection between the crank 1 and the triangular connecting rod is pro...

Embodiment 2

[0081] In practical applications, the combination of the crank mechanism and the triangular linkage-toggle mechanism can be in three different ways: upright (Scheme A), positive bias (Scheme B) and negative bias (Scheme C), such as Figure 7 to Figure 9 Shown; In order to simplify the calculation process of the present invention, the triangular connecting rod of this embodiment is set as an isosceles triangular connecting rod.

[0082] like Figure 7 Shown is a schematic diagram of the structure of the crank-triangular linkage-toggle mechanism upright, that is, when the slider is at the bottom dead center, the rotation center O of the crank 1 1 High AA on the bottom edge of the delta linkage 0 superior. At this time, AA 0 On the horizontal line, the first toggle 2, the second toggle 3 and the third toggle 4 are on the same vertical line, crank R and AA 0 co-existing horizontally. The maximum mechanical benefit A of the equivalent linear link-toggle linkage set up in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com