based on al 2 o 3 Optical fiber ultraviolet sensor of /zno and its manufacturing method

An ultraviolet sensor, sensor technology, applied in the direction of spectrometry/spectrophotometry/monochromator, interference spectroscopy, instruments, etc., to achieve the effect of strong repeatability, easy manipulation, and good transmission spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

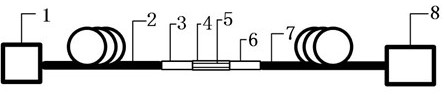

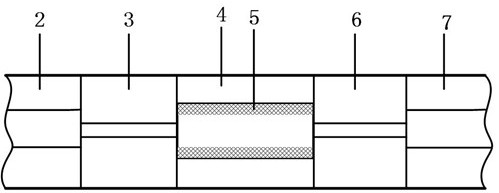

[0028] figure 1 is based on Al according to the present invention 2 o 3 Schematic diagram of the overall structure of the fiber optic UV sensor of / ZnO. like figure 1 The Al-based structure shown in accordance with the present invention 2 o 3 / ZnO optical fiber ultraviolet sensor mainly includes sequentially connected light source 1, introduced single-mode optical fiber 2, first thin-core optical fiber 3, hollow-core optical fiber 4, Al 2 o 3 / ZnO composite material 5, second thin-core fiber 6, leading out single-mode fiber 7 and spectrometer 8. Wherein the light source 1 is a broadband light source with a central wavelength of 1550nm, which is used to generate optical signals; the single-mode fiber 2 is introduced to receive and transmit the light of the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com