All-fiber filter and preparation method thereof

A filter and all-fiber technology, applied in the field of micro-optical components, can solve problems such as difficult to independently adjust the size, a single comb filter, and no reflected light signal, and achieve the effects of easy length, easy device integration, and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

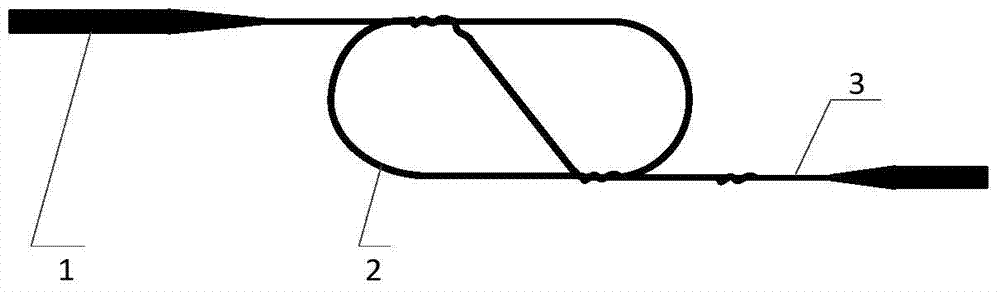

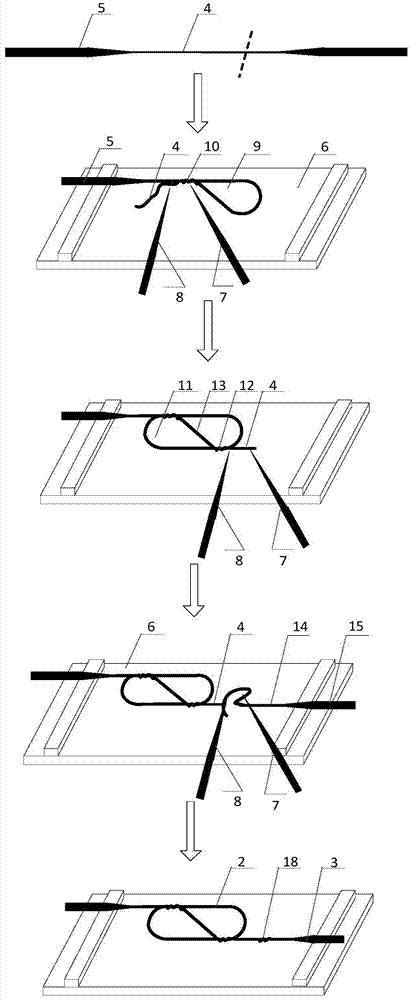

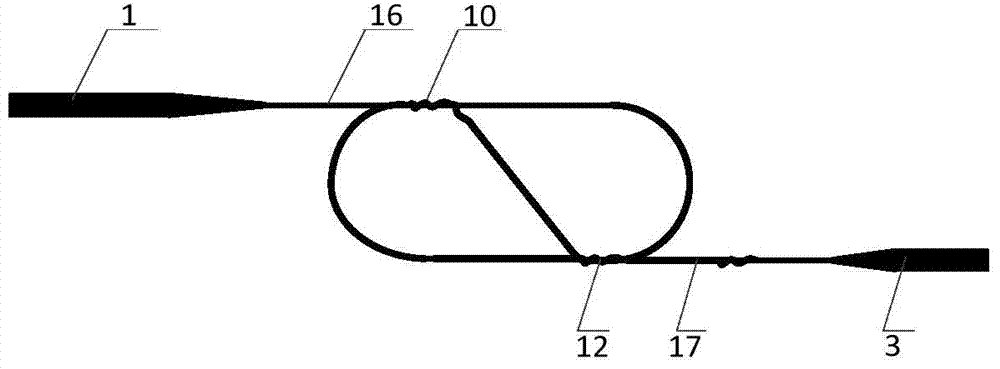

[0083] like Figure 4 As shown, the diameters of the first and second micro-nano optical fibers 1 and 3 are both 1.5 μm, the external refractive index is 1.3316, and the cavity length of the micro-fiber “θ”-shaped resonant structure 2 is 9 mm. k 1 、k 2 are the coupling efficiencies of the first and second coupling regions 10 and 12 respectively, and the tuning reflection spectrum and transmission spectrum of the microfiber "θ" shaped resonant structure 2 corresponding to the coupling efficiency values of the adjustment coupling regions 10 and 12, the coupling regions 10 and 12 The coupling efficiency values are varied from 0.1 to 0.5. In the figure, when the value of the coupling region 10, 12 is 0.1, the stripes in the reflection spectrum and the transmission spectrum are uniform comb stripes, and both the reflection spectrum and the transmission spectrum can be used for comb filtering; and when the coupling efficiency becomes 0.5 When , the peak of each fringe in the ...

Embodiment 2

[0085] like Figure 5 As shown, the diameters of the first and second micro-nano optical fibers 1 and 3 are both 1.5 μm, the external refractive index is 1.3316, the coupling efficiency values of the first and second coupling regions 10 and 12 are both 0.5, and the micro-fiber “θ” The cavity length of the shaped resonant structure 2 changes from 3mm to 5mm, and the number of resonant wavelengths in the reflection spectrum and transmission spectrum of the microfiber "θ" shaped resonant structure 2 in the corresponding 1549nm to 1551nm band changes from three to four, and the free spectrum ranges from 0.571nm is reduced to 0.357nm, and the width of the fringes in the spectrum becomes smaller, which shows that the filtering interval, bandwidth and position of the cavity-length tunable filter of the "θ" shape resonant structure are changed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com