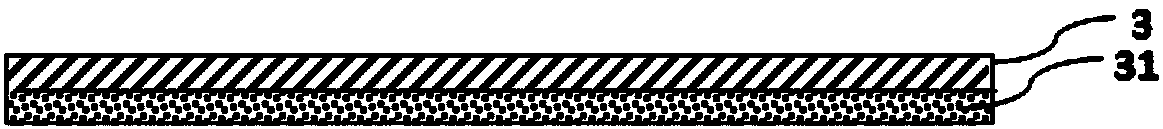

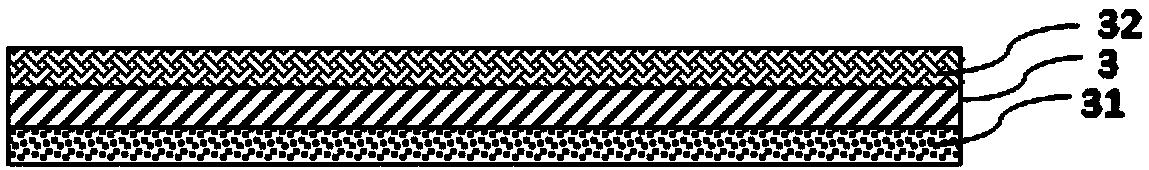

Rigid diaphragm and solid lithium metal battery

A technology of metal batteries and solid lithium, applied in the direction of secondary batteries, battery components, separators/films/diaphragms/spacers, etc., can solve potential safety hazards, short circuits, and hinder the development and practical application of high-capacity battery systems and other issues to achieve the effect of improving cycle stability and reducing the probability of short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the coating in the embodiment of the present application is not particularly limited, and methods known to those skilled in the art can be used, such as spin coating, spray coating or deposition.

[0043] Further optionally, the lithium ion conductor is selected from at least one of lithium-intercalable oxides, elemental coatings, polymer solid electrolytes, sulfide solid electrolytes, and oxide solid electrolytes.

[0044] Among them, the intercalable lithium oxide is selected from SiO, Fe 2 o 3 , CuO, TiO 2 , MnO 2 , SnO, SnO 2 at least one of the

[0045] Wherein, the material of the elemental coating is selected from at least one of Al, In, Mg, Sn, Ge, Si, C, Pb, Sb, and Bi.

[0046]Wherein, the polymer solid electrolyte includes a polymer body and a lithium salt, and the polymer body is selected from at least one of polyether polymers, polyolefin polymers, polynitrile polymers, and polycarboxylate polymers, Lithium salts are selected...

Embodiment 1

[0107] 1. Preparation of the cathode electrode: In the glove box, the active material LiCoO 2 , sulfide solid electrolyte Li 3 P.S. 4 , conductive agent VGCF, and binder styrene-butadiene rubber (number-average molecular weight is about 500,000) are mixed in THF solvent at a weight ratio of 70:20:5:5. After fully stirring and mixing, apply it on the surface of aluminum foil. After drying, it was dried at 60°C, cold pressed, and sliced to obtain LiCoO 2 The cathode active material layer, the thickness of the cathode active material layer is 50 μm.

[0108] 2. Preparation of solid electrolyte diaphragm: In a glove box, the sulfide electrolyte Li 3 P.S. 4 and binder styrene-butadiene rubber at a weight ratio of 99:1, mixed in THF solvent to prepare an electrolyte slurry, coated on the glass surface, and dried at 60°C to obtain an electrolyte membrane, which was sliced to obtain a solid electrolyte with a thickness of 50 μm Diaphragm.

[0109] 3. Rigid diaphragm preparat...

Embodiment 2

[0113] The preparation method is basically the same as in Example 1, except that the thickness of the aluminum foil is replaced from 8 μm to 3 μm during the preparation of the rigid membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com