Intelligent terahertz moxibustion head and manufacturing method thereof

The technology of a terahertz moxibustion head and a manufacturing method, which is applied to the field of intelligently controlled terahertz moxibustion head and its production, can solve the problems of limited effect, poor far-infrared penetration, difficult to achieve the effect of moxibustion, etc., so as to enhance the metabolism of acupoints. Ability, the effect of broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

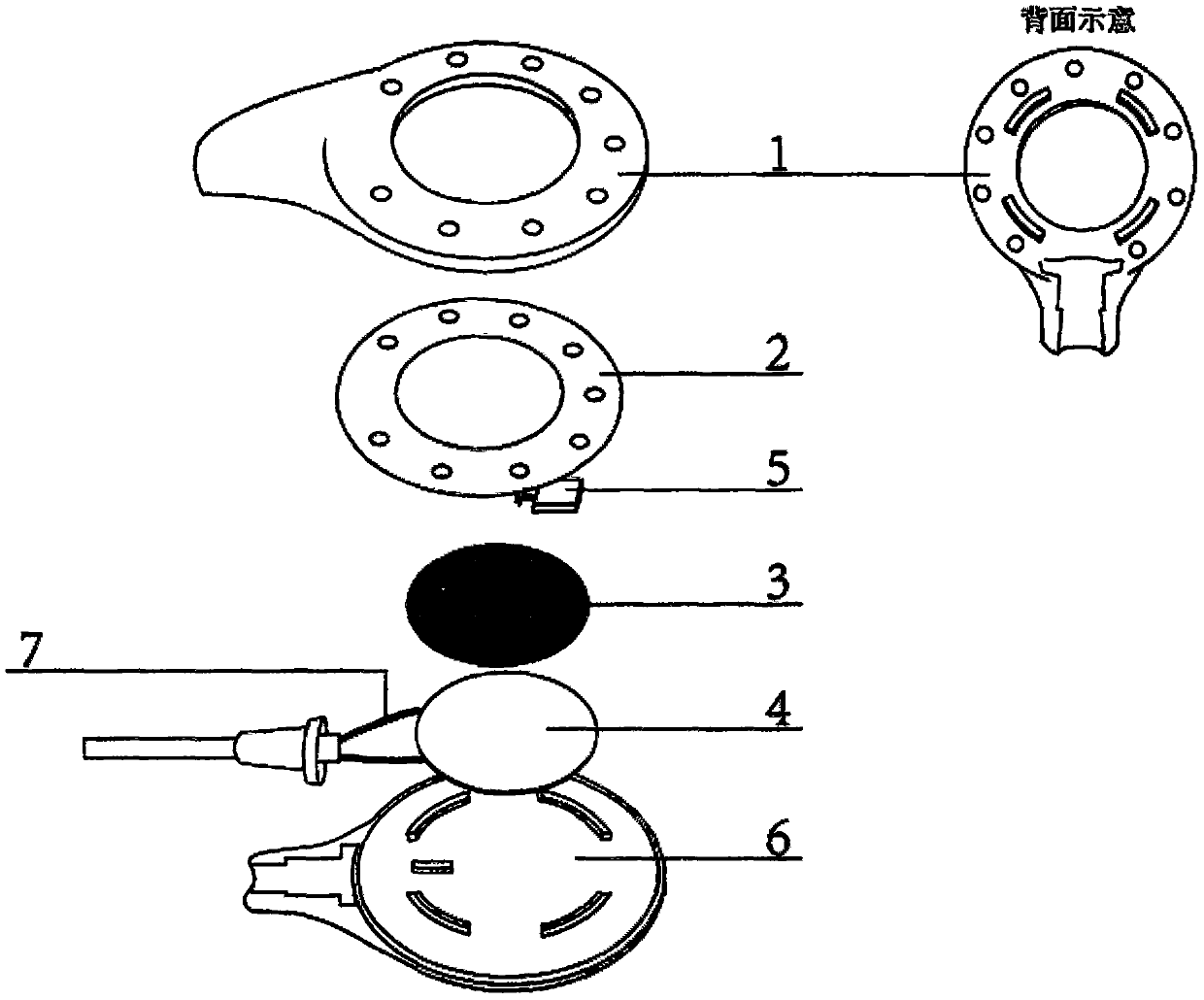

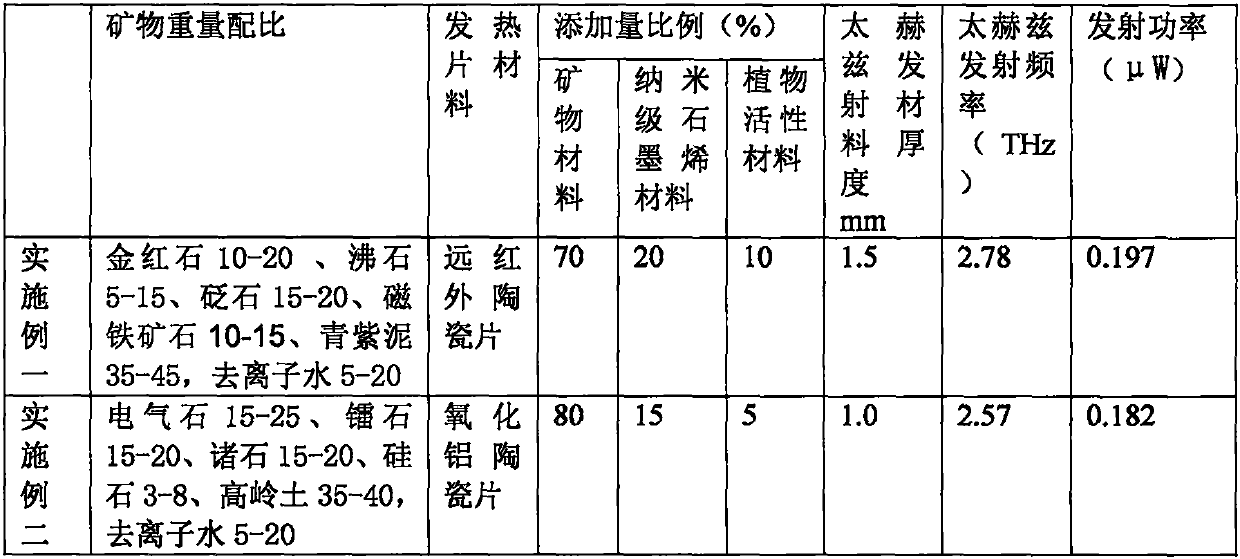

[0038] An intelligent terahertz moxibustion head provided in this embodiment and its manufacturing method include the following steps:

[0039] Step 1, making of natural mineral ceramic crystal material:

[0040] 1. The natural mineral ceramic crystal material is composed of natural minerals: rutile, zeolite, meteorite, magnetite, and purple mud; by weight rutile 10-20, zeolite 5-15, meteorite 15-20, magnetite 10-15 , Qingzi mud 35-45, deionized water 5-20, mix and stir evenly, make ceramic mud, dry in the natural environment, dehydrate at 250-300 ° C, and then sinter at 1100-1200 ° C to form ceramsite, and then pulverize, Pass through a 250-mesh sieve and set aside;

[0041] 2. The graphene material is nano-scale, which is functionalized graphene obtained by oxidation; because of its good thermal conductivity, semiconductor properties and very good optical properties, it can greatly improve the emissivity of terahertz waves; in addition, graphene The good toughness can make...

Embodiment 2

[0055] Step 1, making of natural mineral ceramic crystal material:

[0056] 1. The natural mineral ceramic crystal material is composed of natural minerals: tourmaline, Guiyang stone, various stones, silica, kaolin; by weight, tourmaline 15-25, radium stone 15-20, various stones 15-20, silica 3-8. Kaolin 35-40, deionized water 5-20, mix and stir evenly, make ceramic mud, dry in natural environment, dehydrate at 250-300°C, and sinter at 1100-1200°C to form ceramsite, and then Crush, pass through a 250-mesh sieve, and set aside;

[0057] 2. The manufacture of the graphene nanoscale material is the same as that in Example 1.

[0058] 3. The production of the plant active material is the same as in Example 1.

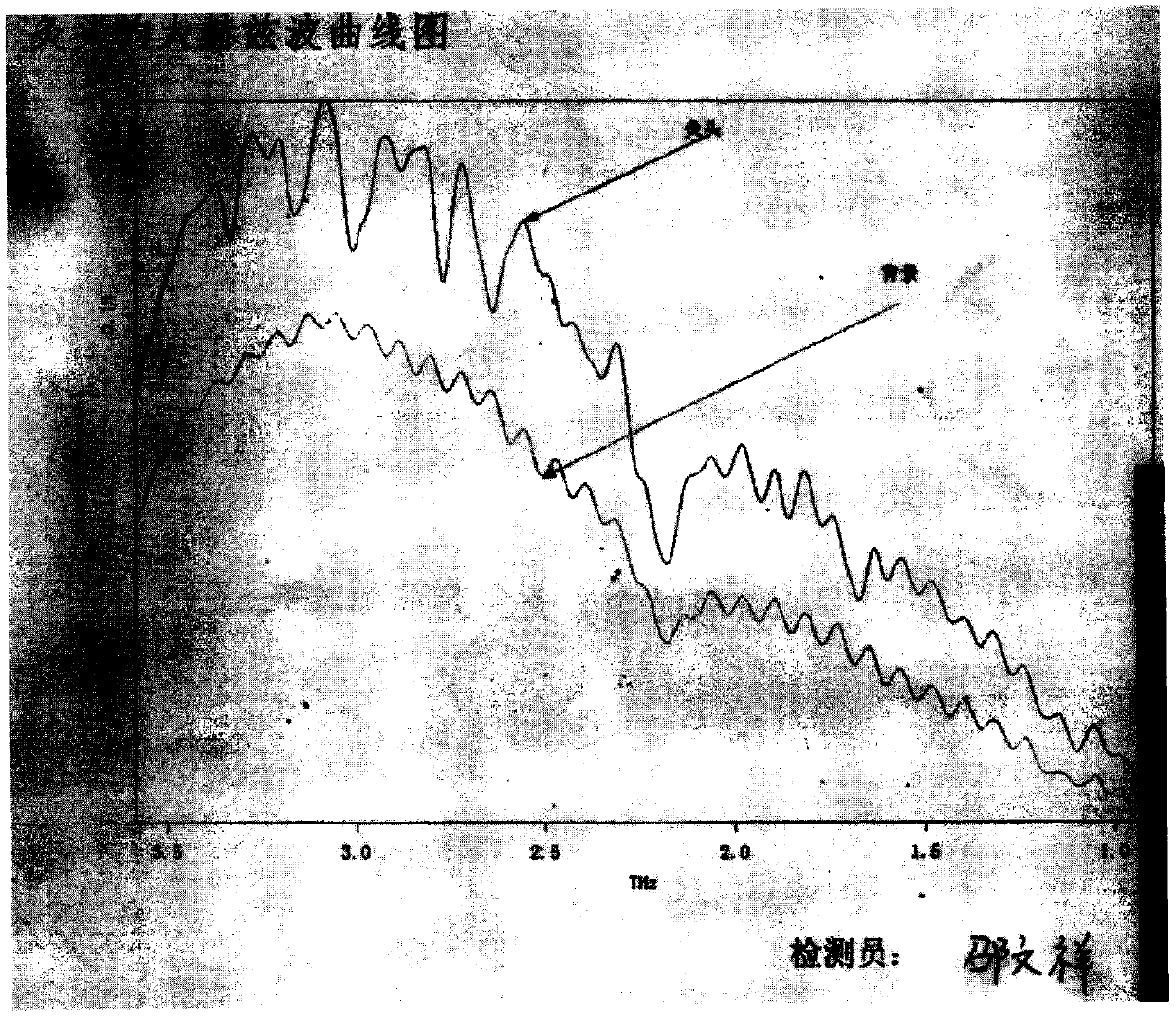

[0059] 4. The terahertz wave treatment is to mix the above-mentioned natural mineral ceramic crystal material, nano-scale graphene material, and plant active material in a weight ratio of 80:15:5, and select the model MKR-AX terahertz wave during the stirring process. Th...

Embodiment 3

[0066] Step 1, making of natural mineral ceramic crystal material:

[0067] 1, the described natural mineral ceramic crystal material is made up of natural minerals: rutile, tourmaline, various stones, magnetite ore, purple mud; By weight rutile 10-20, tourmaline 15-25, various stones 15-20, magnet Ore 10-15, cyan clay 35-45, deionized water 5-20, mix and stir evenly, make ceramic mud, dry in natural environment, dehydrate at 250-300°C, and sinter at 1100-1200°C to form ceramsite , then pulverized, passed through a 250-mesh sieve, and set aside;

[0068] 2. The manufacture of the graphene nanoscale material is the same as that in Example 1.

[0069] 3. The production of the plant active material is the same as in Example 1.

[0070] 4. The terahertz wave treatment is to mix the above-mentioned natural mineral ceramic crystal materials, nano-scale explanatory materials, and plant active materials in a weight ratio of 85:10:5, and use the model MKR-AX terahertz wave during the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com