Image recognition based molten iron KR stirring and desulfurizing method

A stirring desulfurization and image recognition technology, which is applied in image enhancement, image analysis, image data processing, etc., can solve the problem that the influence relationship of process parameters cannot be known, it is difficult to avoid manual operation and human interference, and the closed stirring process detection of large eddy current pyrometallurgical reaction process Difficult monitoring and other issues to ensure efficient entrainment circulation and mixing and dispersing effects, improve kinetic conditions of molten iron KR stirring desulfurization reaction and desulfurization technical and economic indicators, and ensure efficient mixing and dispersing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

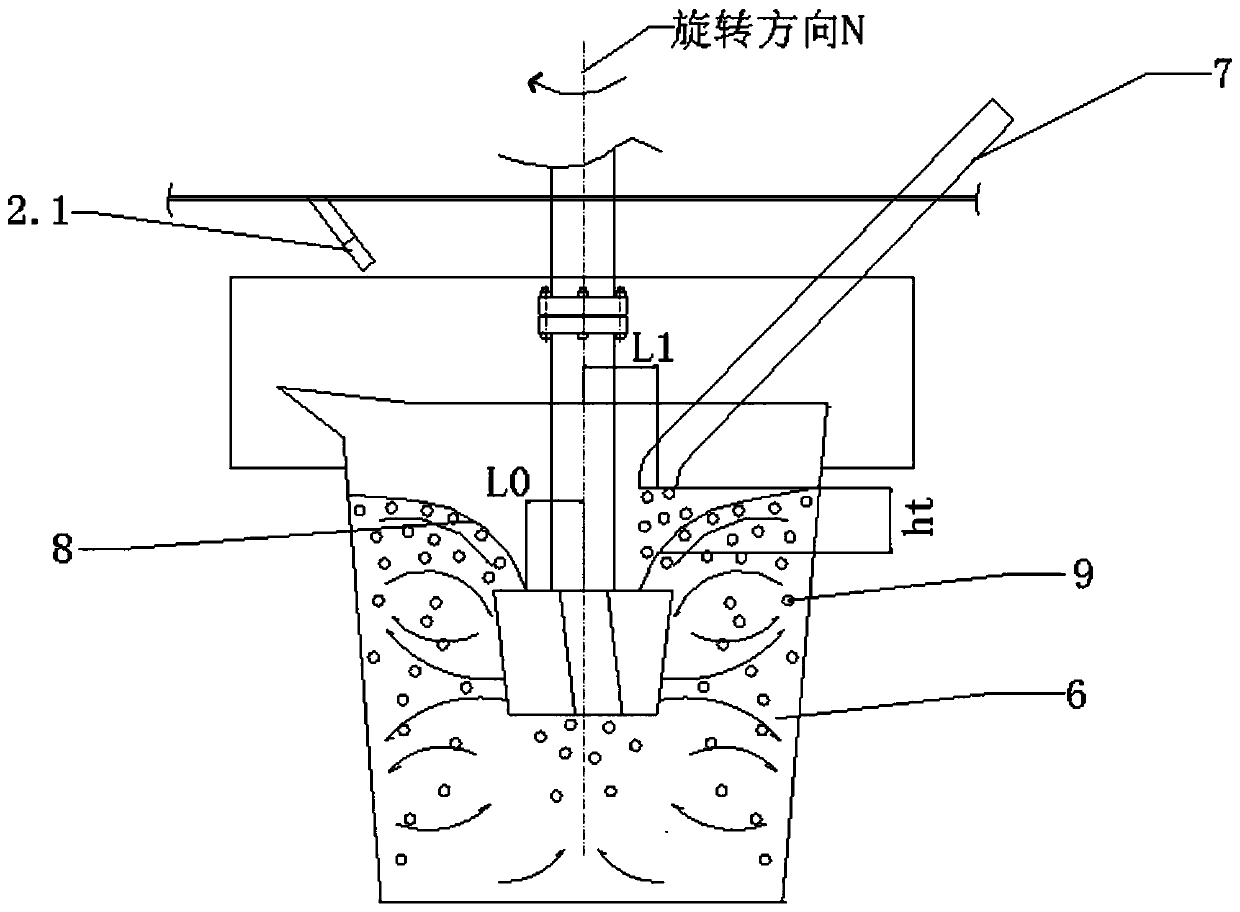

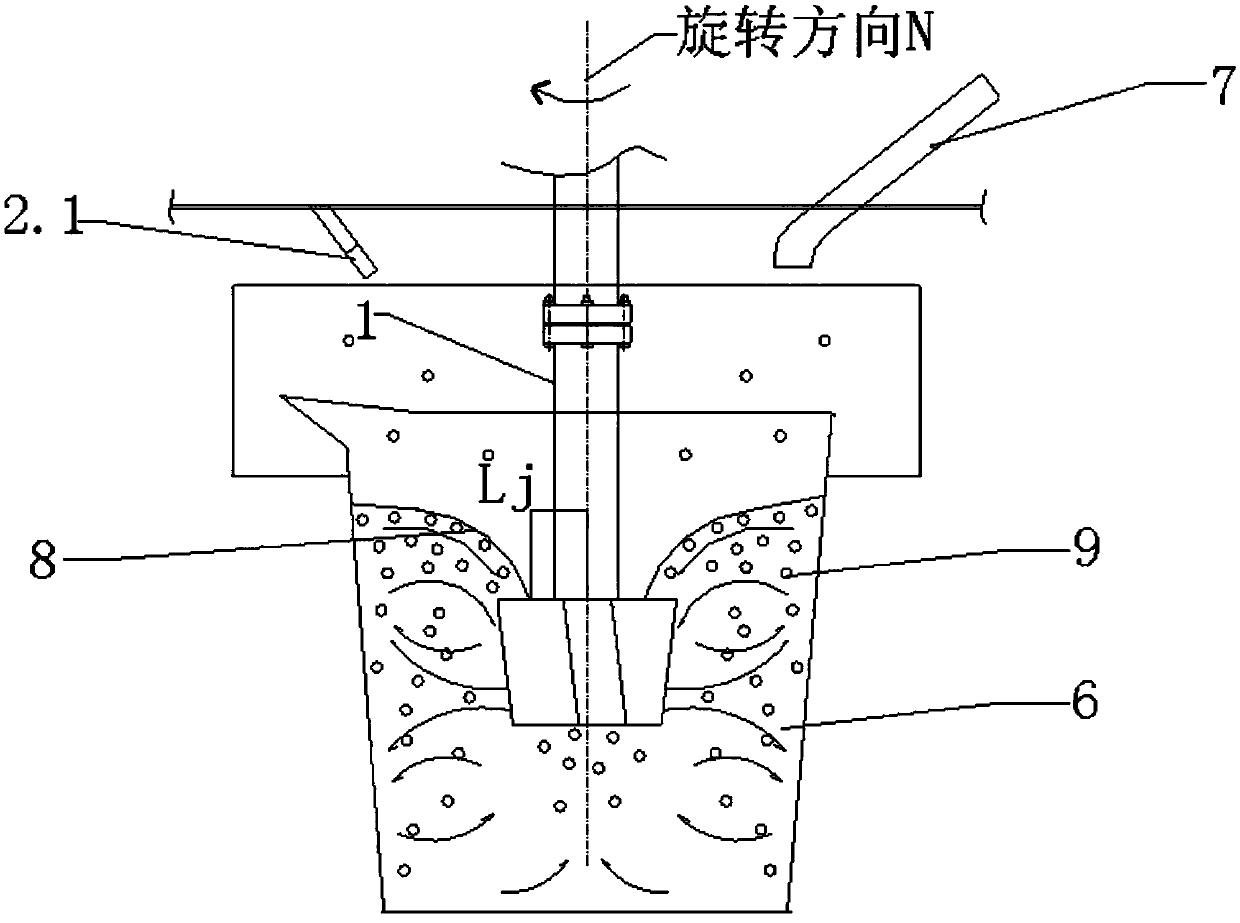

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings.

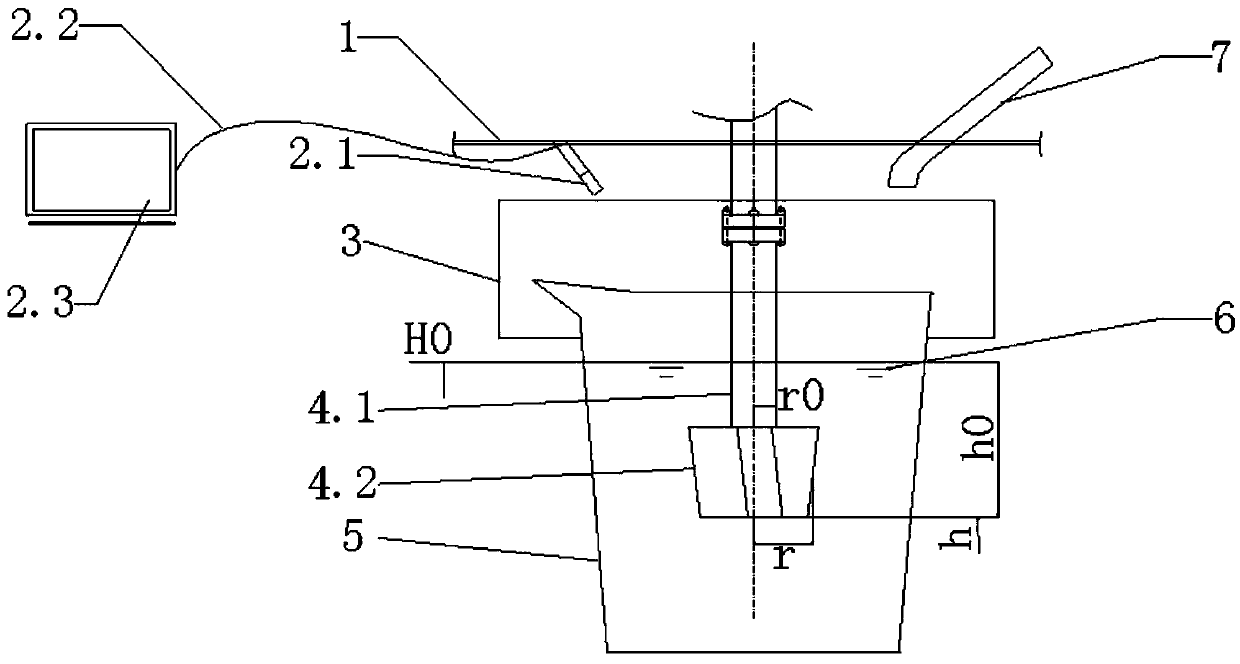

[0025] The image recognition-based KR stirring desulfurization method for molten iron provided by the embodiment of the present invention adopts a high-definition video system 2 and includes specific stirring desulfurization operation steps, wherein the high-definition video system 2 is mainly composed of a high-definition camera 2.1 with a dust removal and purging device, The data transmission line is composed of a conversion device 2.2, a video image display 2.3, etc., and the high-definition camera 2.1 is aimed at the stirring vortex liquid surface 8 of the molten iron tank 5, and is installed at the lower part of the stirring desulfurization platform 1, and the video image display 2.3 is installed in the operation room, through the data transmission line Data connection with conversion device 2.2 and HD camera 2.1 with dust removal and blowing device.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com