Solar water heater with evaporation end flow homogenizing pipe diameter changes

A solar water heater and evaporator technology, applied in the field of solar energy, can solve the problems affecting the efficiency of heat exchange and the decline of heat exchange capacity, and achieve the effects of promoting smooth flow, inhibiting backflow, and evenly dividing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

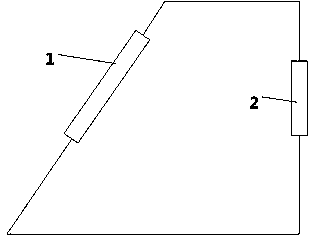

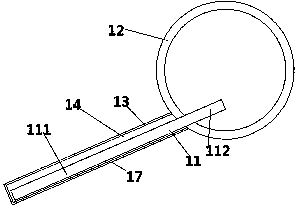

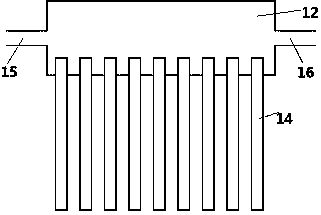

[0049] A solar water heater (collector) system, such as figure 1 As shown, the system includes a heat collector 1 and a heat utilization device 2. The heat collector 1 includes a heat collection pipe 11 and a water tank 12. The heat collection pipe 11 is actually an independent heat pipe, including an evaporation end 111 and a condensation pipe. end 112 , the condensation end 112 is set in the water tank 12 . The evaporating end 111 absorbs solar energy, and transfers heat to the water in the water tank through the condensing end 112 . The water tank 12 communicates with the heat utilization device 2 to form a circulation loop. The heat collecting tube 11 absorbs solar energy to heat the water in the water tank 12. The heated water enters the heat utilization device 2 through the water tank outlet pipe 17, and is exchanged in the heat utilization device 2. Heat, the water flowing out from the heat utilization device 2 enters the water tank 12 through the water tank inlet pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com