Penning ion source based on hollow cathode discharge

A hollow cathode discharge, Penning ion source technology, applied in discharge tubes, ion beam tubes, circuits, etc., can solve the problems of affecting ion source insulation, easy pollution, coating pollution, etc., to increase the effective movement stroke, reduce Contamination, improve stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] see Figure 4.1 As shown: the magnetic field of the magnetic pole 13 is a single-polarity magnetic field formed by permanent magnets, and the single-polarity magnetic field is a magnetic group formed by magnets of the same polarity that is set on the anode cylinder 132, and its magnetic field direction is parallel to the axial direction Under the action of a single polar magnetic field, the electrons move spirally under the influence of the magnetic field, which increases the effective stroke in the discharge chamber of the anode cylinder, increases the number of collisions with the process gas, and generates more electrons at the same time.

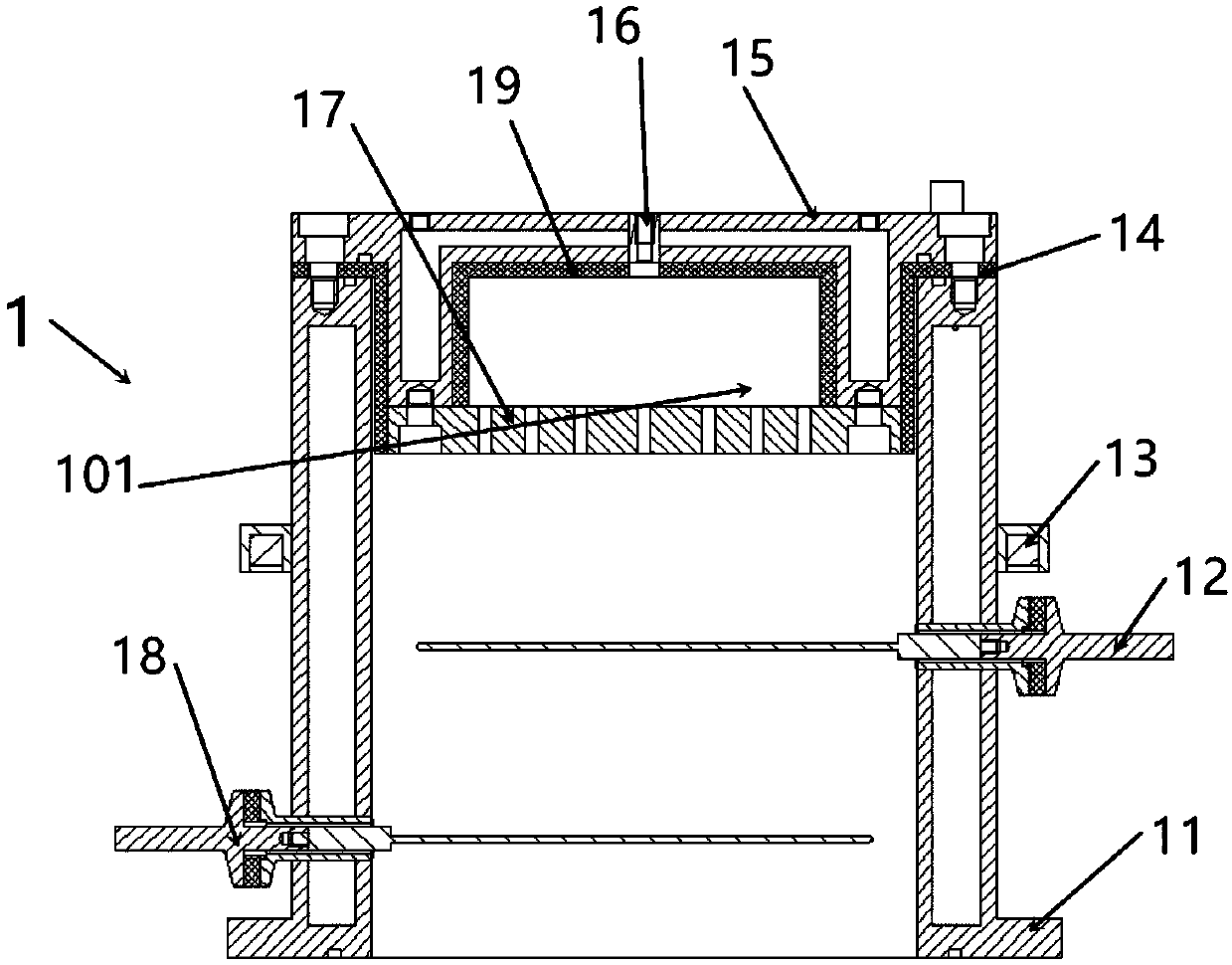

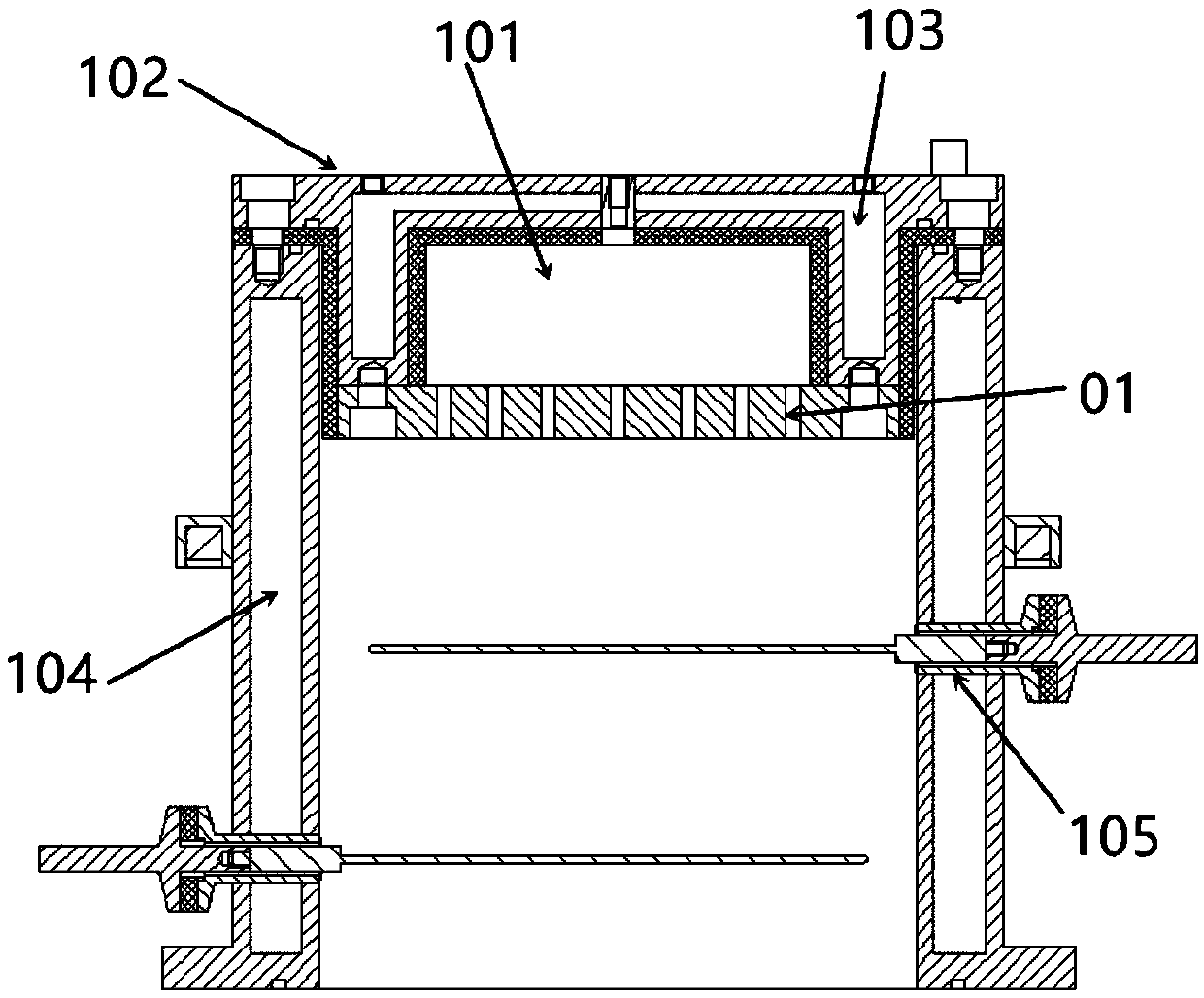

[0041] see Figure 6 Shown:

[0042] The hollow cathode plate 17 is provided with a plurality of groups of holes 01, the hollow cathode plate 17 and the cathode grid 12 are applied with the negative voltage of the same potential, the anode cylinder 11 is loaded with positive electricity, and the accelerating pole 18 is loaded wit...

Embodiment 2

[0049] The difference between the magnetic poles of this embodiment and the first embodiment is that the magnetic field of the magnetic pole 13 is an electromagnetic coil, which provides a stable and controllable electromagnetic field for the electron source. The electromagnetic coil is a conventional single-phase wound electromagnetic coil, on which various waveforms such as sine, cosine, square wave, and triangle wave can be applied, and a load with adjustable frequency and current can be formed in the anode cylinder 11 correspondingly. With a certain oscillating magnetic field, the movement of electrons in the oscillating magnetic field can further increase the effective movement distance compared with a single polarity magnetic field, and can collide with more process gases to generate more electrons.

[0050] see Figure 4.2 As shown: the magnetic field of the magnetic pole 13 is the magnetic field of the electromagnetic coil formed by the permanent magnet. The magnetic g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com