Permanent magnet fault-tolerant motor driving system for electric vehicle and control method thereof

A motor drive system, permanent magnet fault-tolerant technology, applied in motor control, AC motor control, estimation/correction of motor parameters, etc. The effect of motor output performance, simple structure and small quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

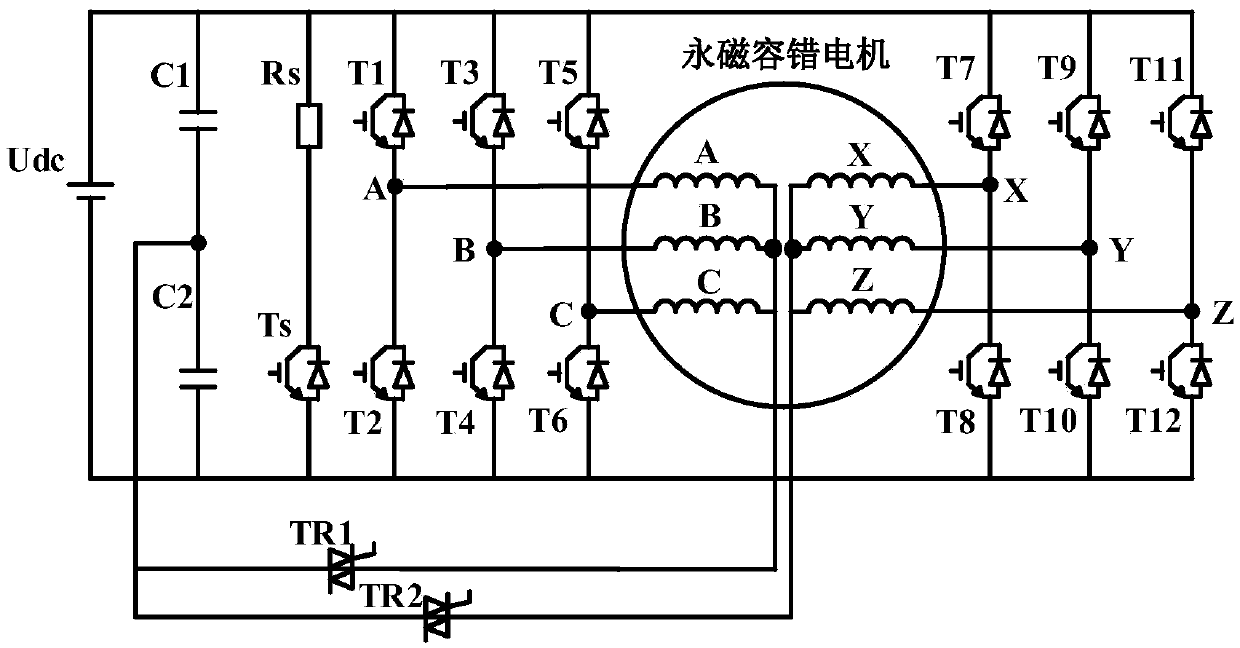

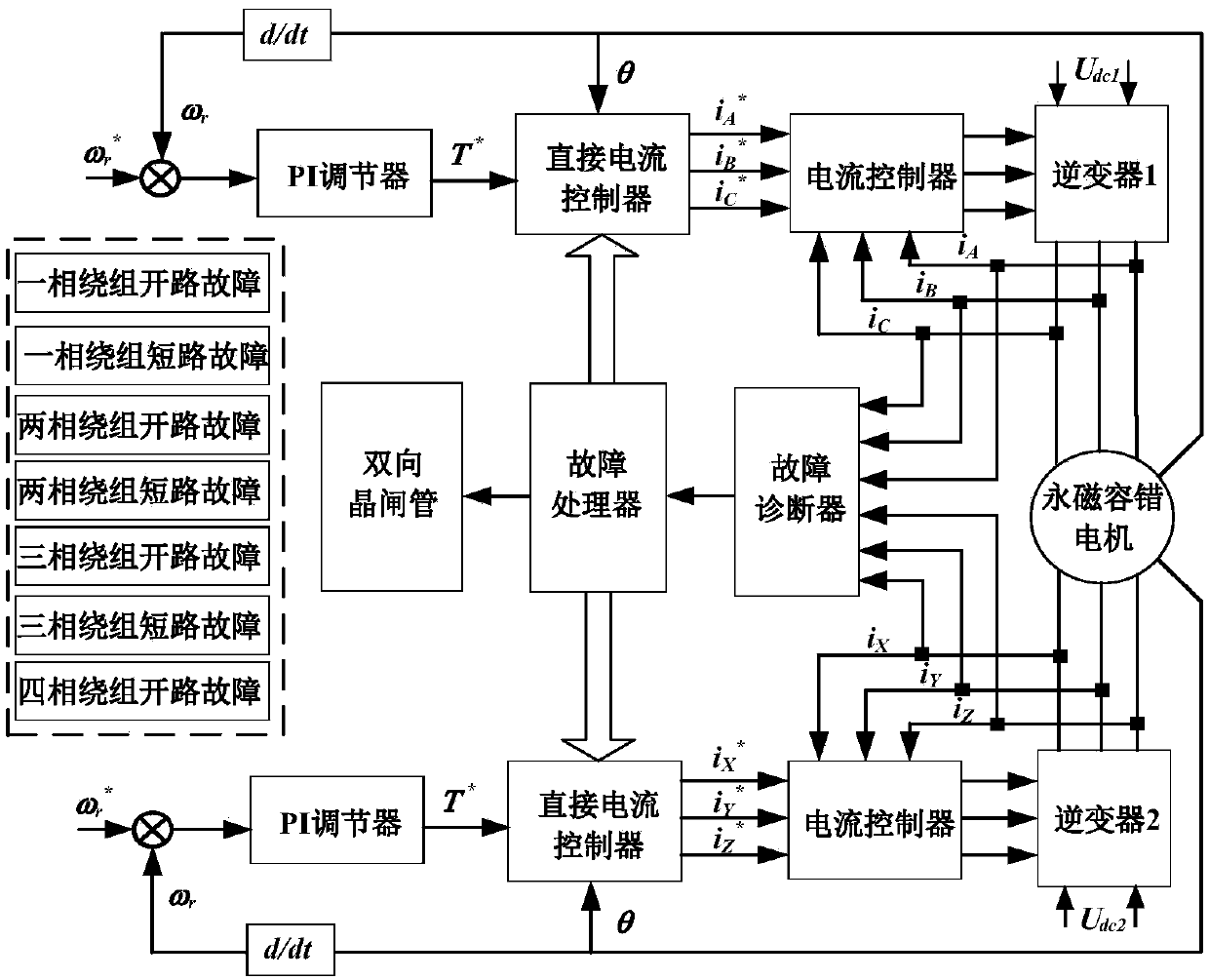

[0045] combine figure 1 , the high reliability permanent magnet fault-tolerant motor drive system for electric vehicles of the present invention includes a high-reliability permanent magnet fault-tolerant motor, first to thirteenth power switch tubes, braking resistors, a first bidirectional thyristor, a second bidirectional thyristor, an independent DC power supply, first electrolytic capacitor and second electrolytic capacitor;

[0046] The high-reliability permanent magnet fault-tolerant motor is an outer rotor hub-type permanent magnet fault-tolerant motor, and its stator includes two sets of mutually independent and symmetrical three-phase single-layer centralized armature windings wound with teeth separated by ABC windings. and XYZ windings;

[0047] The first to twelfth power switch tubes form two sets of three-phase full-bridge drive circuits, which are respectively the first to sixth power switch tubes T1, T2, T3, T4, T5, T6 and the seventh to twelfth power switch tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com