Polyvinyl alcohol hydrogel as well as preparation method and application thereof

A polyvinyl alcohol and hydrogel technology, which is used in pharmaceutical formulations, medical preparations with non-active ingredients, and medical preparations containing active ingredients, can solve the problems of non-degradable polymers and high cytotoxicity, and achieve improved The effect of drug availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

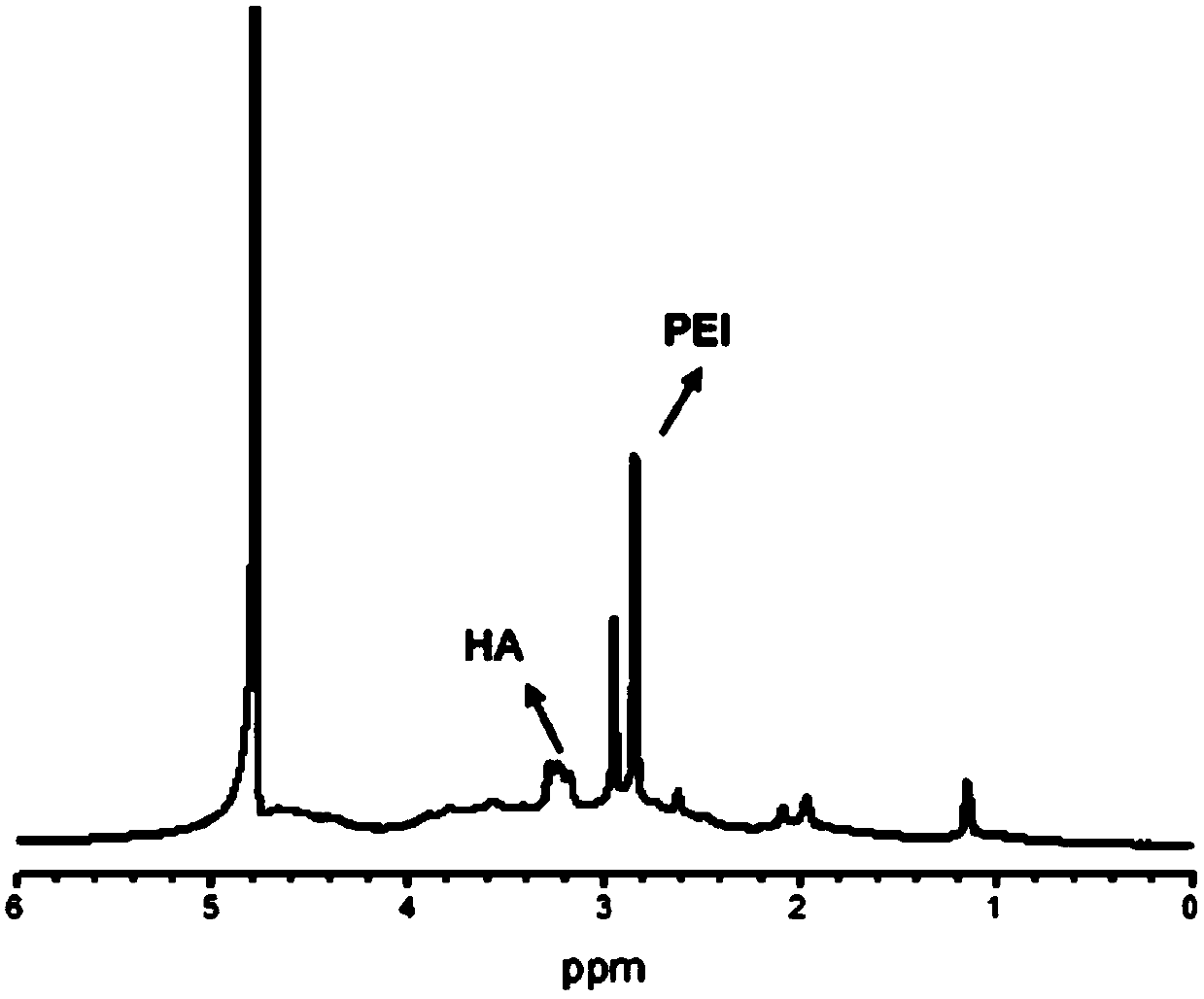

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of polyvinyl alcohol hydrogel, comprising the steps of:

[0038] (1) Prepare polyvinyl alcohol aqueous solution: add 10g polyvinyl alcohol into 100mL deionized water, stir until dissolved at 90°C to obtain polyvinyl alcohol aqueous solution, save it for later use;

[0039] (2) Preparation of loaded oridin / sodium alginate microsphere complex: mix 1mL Tween 80 and 100mL olive oil, stir at room temperature at 800r / min for 1h, add 20mL sodium alginate aqueous solution with a mass concentration of 2% dropwise into the olive oil, continue to stir at room temperature for 1 hour, and finally add calcium chloride solution with a mass concentration of 2.5% and 50 mg oridin and stir overnight; the solution is washed three times by centrifugation with isopropanol and deionized water at a centrifugal speed of 10,000 r / min. Centrifuge for 15 minutes each time, and finally freeze-dry at -60°C for 24 hours to obtain the loaded oridin / sodium alginate microsphere com...

Embodiment 2

[0049] A preparation method of polyvinyl alcohol hydrogel material, comprising the steps of:

[0050] (1) Prepare polyvinyl alcohol aqueous solution: add 15g polyvinyl alcohol into 100mL deionized water, stir until dissolved at 90°C to obtain polyvinyl alcohol aqueous solution, save it for later use;

[0051] (2) Preparation of loaded oridin / sodium alginate microsphere complex: mix 1mL Tween 80 and 100mL olive oil, stir at room temperature at 800r / min for 1h, add 20mL sodium alginate aqueous solution with a mass concentration of 2% dropwise into the olive oil, continue to stir at room temperature for 1 hour, and finally add calcium chloride solution with a mass concentration of 2.5% and 100 mg oridin and stir overnight; the solution is washed three times by centrifugation with isopropanol and deionized water, and the centrifugal speed is 10000r / min. Centrifuge for 15 minutes each time, and finally freeze-dry at -60°C for 24 hours to obtain the loaded oridin / sodium alginate mic...

Embodiment 3

[0057] A preparation method of polyvinyl alcohol hydrogel material, comprising the steps of:

[0058] (1) Prepare polyvinyl alcohol aqueous solution: add 20g polyvinyl alcohol into 100mL deionized water, stir until dissolved at 90°C to obtain polyvinyl alcohol aqueous solution, save it for later use;

[0059] (2) Preparation of loaded oridin / sodium alginate microsphere complex: mix 1mL Tween 80 and 100mL olive oil, stir at room temperature at 800r / min for 1h, add 20mL sodium alginate aqueous solution with a mass concentration of 3% dropwise into the olive oil, continue to stir at room temperature for 1 hour, and finally add calcium chloride solution with a mass concentration of 5% and 100 mg oridin and stir overnight; the solution is washed three times by centrifugation with isopropanol and deionized water, and the centrifugal speed is 10000r / min. Centrifuge for 15 minutes each time, and finally freeze-dry at -60°C for 24 hours to obtain the loaded oridin / sodium alginate micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com