Fe2O3-CeO2/SiO2 solid base catalyst as well as preparation method and application thereof

A solid base catalyst, fe2o3-ceo2 technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve harsh reaction conditions, high production costs, equipment Large investment and other problems, to achieve the effect of simple preparation method, less by-products, and lower reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

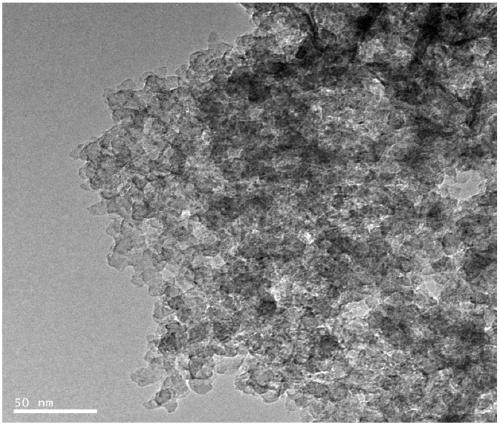

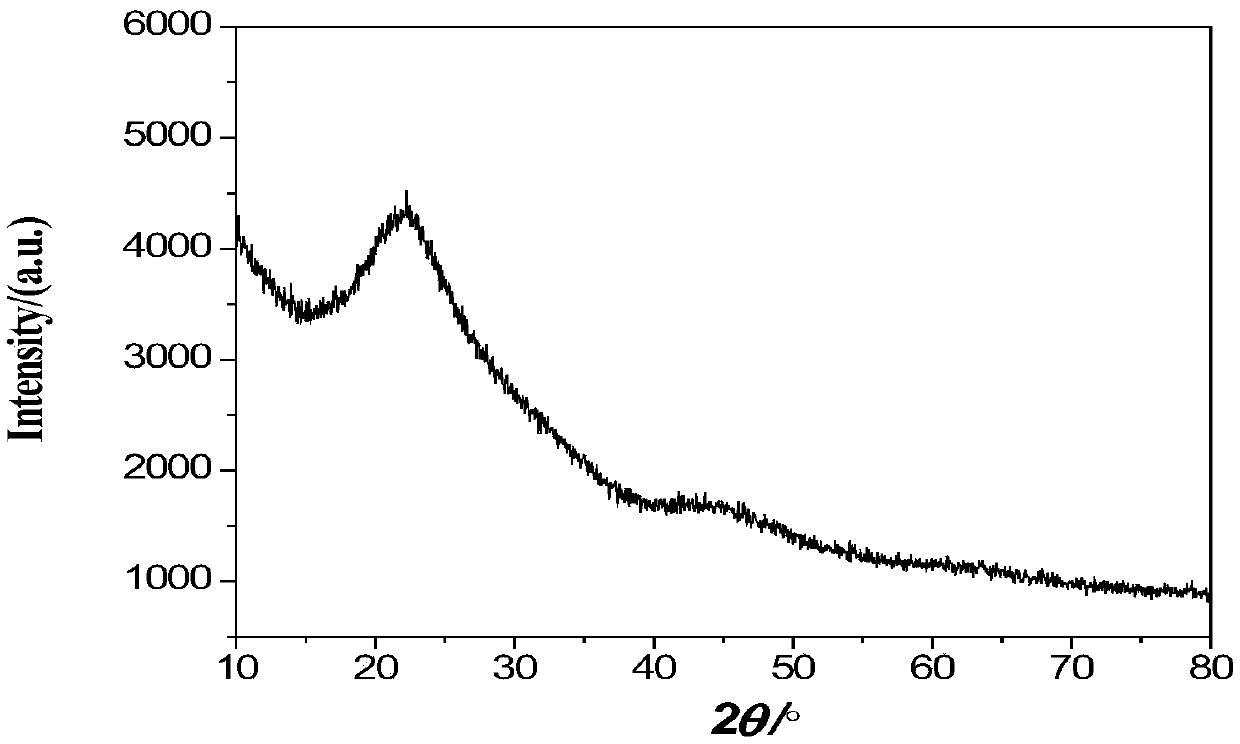

Embodiment 1

[0033] 1.44gFe(NO3 ) 3 9H 2 O, 1.0gCe(NO 3 ) 3 ·6H 2 O, dissolved in 60g of water and 32g of absolute ethanol to make a mixed solution. At 30 °C, the above mixed solution was impregnated in 3.4 g SiO 2 The catalyst precursor was obtained on the support and stirred for 1.5 hours. Add dropwise 50ml of KBH with a concentration of 0.5mol / L to the impregnated catalyst precursor 4 Aqueous solution, soak for 1 hour after dropwise addition. Filter, wash with 250ml of deionized water, wash with 250ml of methanol, put the solid into an oven after drying, and dry it under vacuum for 4 hours at 25°C to obtain Fe 2 o 3 -CeO 2 / SiO 2 catalyst.

Embodiment 2

[0035] 1.44gFe(NO 3 ) 3 9H 2 O was dissolved in 60g of water and 32g of absolute ethanol to make a mixed solution. At 30 °C, the above mixed solution was impregnated in 3.8 g SiO 2 The catalyst precursor was obtained on the support and stirred for 1.5 hours. Add dropwise 50ml of KBH with a concentration of 0.5mol / L to the impregnated catalyst precursor 4 Aqueous solution, soak for 1 hour after dropwise addition. Filter, wash with 250ml of deionized water, wash with 250ml of methanol, put the solid into an oven after drying, and dry it under vacuum for 4 hours at 25°C to obtain Fe 2 o 3 / SiO 2 catalyst.

Embodiment 3

[0037] 1.0gCe(NO 3 ) 3 ·6H 2 O was dissolved in 60g of water and 32g of absolute ethanol to make a mixed solution. At 30 °C, the above mixed solution was impregnated in 3.6 g SiO 2 The catalyst precursor was obtained on the support and stirred for 1.5 hours. Add dropwise 50ml of KBH with a concentration of 0.5mol / L to the impregnated catalyst precursor 4 Aqueous solution, soak for 1 hour after dropwise addition. Filter, wash with 250ml deionized water, wash with 250ml methanol, put the solid into an oven after drying, and dry it in vacuum at 25°C for 4 hours to obtain CeO 2 / SiO 2 catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com