Preparation method and application of nanoporous gold-based catalyst modified by atomic layer deposition ultrathin titanium oxide

A technology of atomic layer deposition and catalyst, which is applied in the direction of molecular sieve catalyst, preparation of organic compounds, physical/chemical process catalyst, etc., can solve the problem of aspect ratio limitation modification, etc., to solve the cumbersome and time-consuming steps, and solve the problem of uneven deposition , the effect of improving catalyst performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Preparation of Nanoporous Gold-Based Catalysts Modified by Titanium Oxide Ultrathin

[0027] S1, put 5mLH 4 AuCl 4 4H 2 O (6 mM) was added to 20 mL of water. Then 500 mg of SBA-15 was slowly added to the solution. The pH value of the solution was adjusted to 9.0 with aqueous ammonia, and finally the mixture was vigorously stirred for 24 h under dark conditions. The mixture was then filtered and washed several times with deionized water to remove residual chloride ions. Finally, the obtained solid was dried at room temperature under vacuum for 24 h, and used as a catalyst precursor.

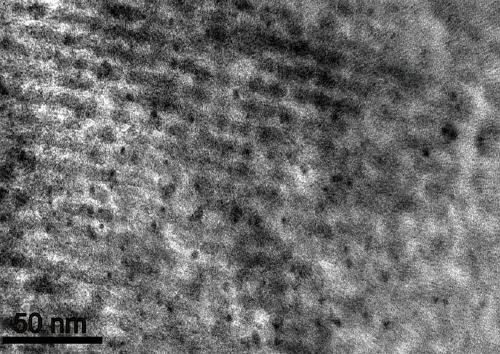

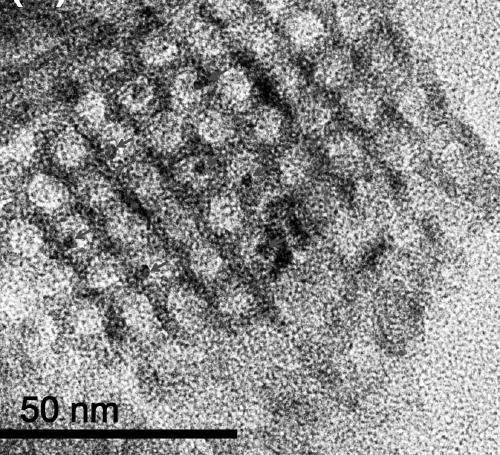

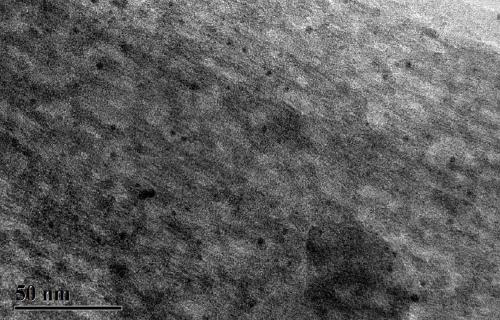

[0028] S2, place the previous body in H 2 A gold nanoparticle catalyst confined on the inner wall of the silica (SBA-15) with mesoporous channels was obtained by reduction at 200 °C for 2 h in a gas atmosphere, named SBA-15 / Au.

[0029] S3. Weigh 10 mg of the powder sample prepared in step S2, disperse it with an appropriate amount of ethanol, and after ultrasonic dispersi...

Embodiment 2

[0031] Example 2: Preparation of Nanoporous Gold-Based Catalysts Modified by Titanium Oxide Ultrathin

[0032] S1, put 5mLH 4 AuCl 4 4H 2 O (6 mM) was added to 20 mL of water. Then 500 mg of SBA-15 was slowly added to the solution. The pH value of the solution was adjusted to 9.0 with aqueous ammonia, and finally the mixture was vigorously stirred for 24 h under dark conditions. The mixture was then filtered and washed several times with deionized water to remove residual chloride ions. Finally, the obtained solid was dried at room temperature under vacuum for 24 h, and used as a catalyst precursor.

[0033] S2, place the previous body in H 2 A gold nanoparticle catalyst confined on the inner wall of the SBA-15 channel was obtained by reduction at 200 °C for 2 h in a gas atmosphere, named SBA-15 / Au.

[0034] S3. Weigh 10 mg of the powder sample prepared in step S2, disperse it with an appropriate amount of ethanol, and after ultrasonic dispersion, drop the suspension on...

Embodiment 3

[0036] Example 3: Preparation of Nanoporous Gold-Based Catalysts Modified by Titanium Oxide Ultrathin

[0037] S1, put 5mLH 4 AuCl 4 4H 2 O (6 mM) was added to 20 mL of water. Then 500 mg of SBA-15 was slowly added to the solution. The pH value of the solution was adjusted to 9.0 with aqueous ammonia, and finally the mixture was vigorously stirred for 24 h under dark conditions. The mixture was then filtered and washed several times with deionized water to remove residual chloride ions. Finally, the obtained solid was dried at room temperature under vacuum for 24 h, and used as a catalyst precursor.

[0038] S2, place the previous body in H 2 A gold nanoparticle catalyst confined on the inner wall of the SBA-15 channel was obtained by reduction at 200 °C for 2 h in a gas atmosphere, named SBA-15 / Au.

[0039] S3. Weigh 10 mg of the powder sample prepared in step S2, disperse it with an appropriate amount of ethanol, and after ultrasonic dispersion, drop the suspension onto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com