Lead-zinc mine tailings pond and adjacent soil composite heavy metal pollution repairing system

A technology of pollution remediation and soil remediation agent, applied in the field of lead-zinc mine tailings pond and adjacent soil composite heavy metal pollution remediation system, can solve the problems of inability to deeply treat soil, damage to soil ecological environment, and high processing cost, and achieve the elimination of hardening. phenomenon, reducing re-leaching, and improving the effect of pellet structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

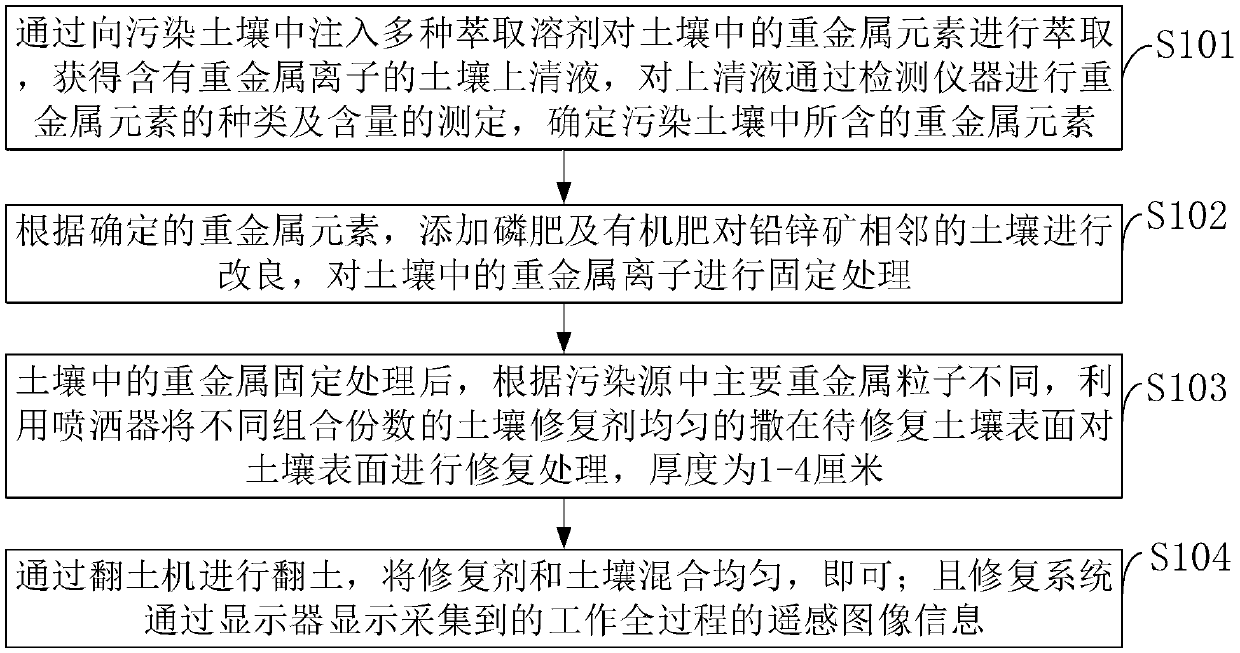

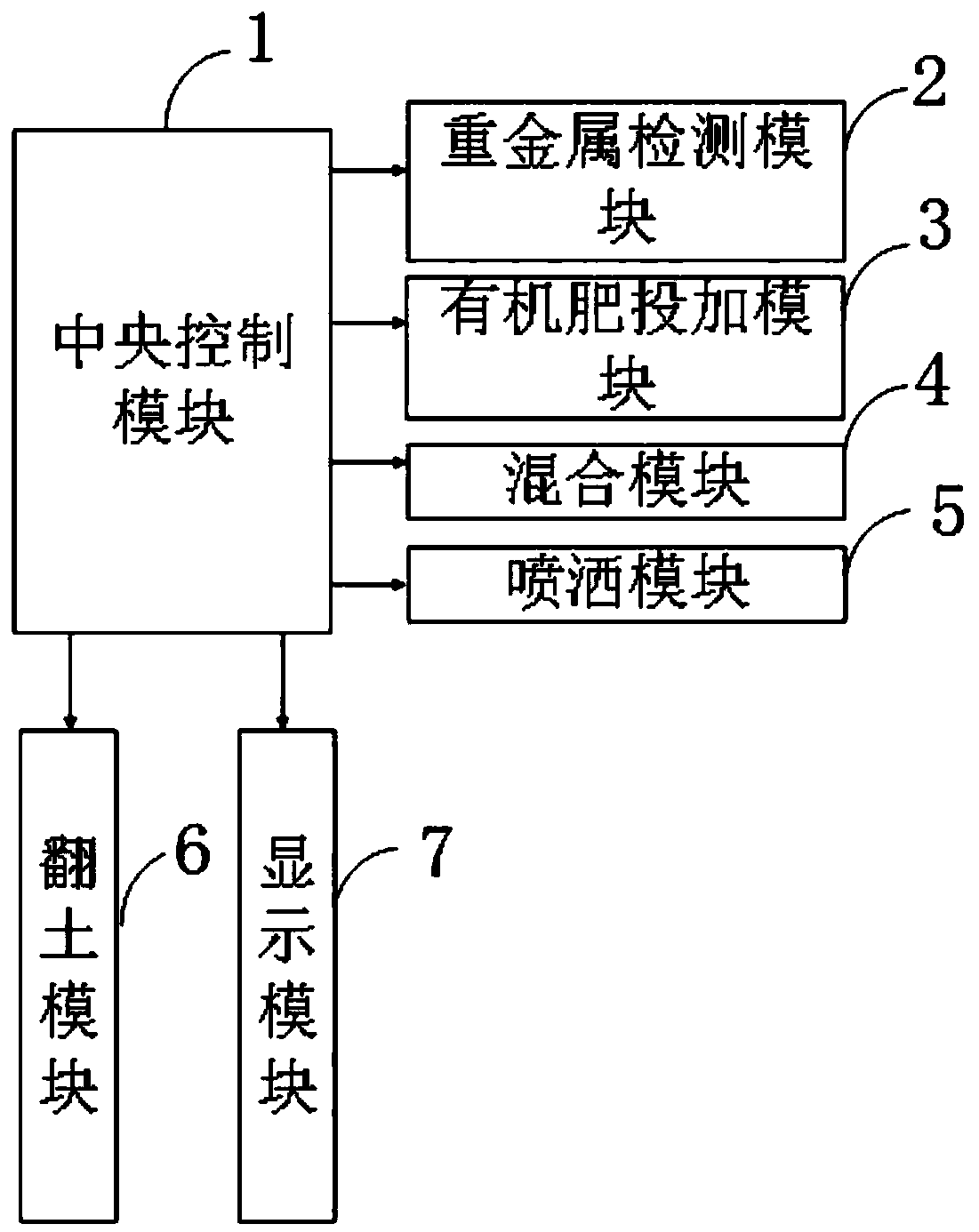

Method used

Image

Examples

preparation example Construction

[0062] In step S103, the steps of the general preparation method of the soil remediation agent provided by the embodiment of the present invention are as follows:

[0063] 1) Crushing the biomass with a grinder, passing through a 100-200 mesh sieve, exposing the obtained biomass powder to the sun, and using a reactor to uniformly mix the biomass powder and the microbial agent to obtain a mixture 1;

[0064] 2) uniformly mixing sulfoaluminate cement and silica fume to obtain mixture 2;

[0065] 3) After the mixtures 1 and 2 are fully mixed, the soil remediation agent of the present invention is obtained.

[0066] In step S103, the amount of the soil remediation agent provided by the embodiment of the present invention is 6%-10% of the mass of the soil, followed by spraying and watering, and the quality of water used for spraying and sprinkling is 70%-80% of the mass of the soil remediation agent.

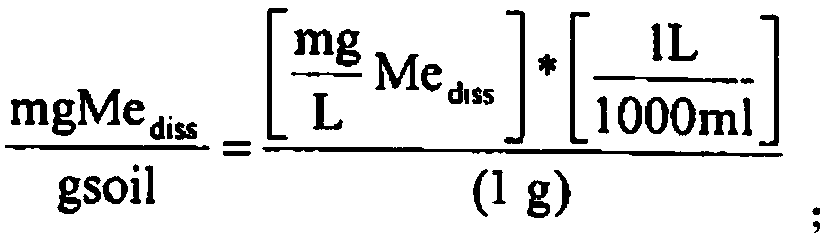

[0067] The assay method that heavy metal exists in the beneficiation liquid tha...

Embodiment 1

[0095] The soil remediation agent provided by the embodiment of the present invention consists of 20 parts of sulfoaluminate cement, 10 parts of silica fume, 28 parts of biomass and 8 parts of microbial agent according to the mass parts.

Embodiment 2

[0097] The soil remediation agent provided by the embodiment of the present invention consists of 40 parts of sulfoaluminate cement, 20 parts of silica fume, 38 parts of biomass, and 16 parts of microbial agent according to the parts by mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com