Anti-seepage treatment process of connecting flange

A treatment process and anti-seepage technology, which is applied to flange connections, pipes/pipe joints/fittings, passing components, etc., and can solve problems such as inconvenient installation and removal of internal gaskets, flange plate water seepage, liquid leakage, etc. , to achieve the effect of reducing process cost, avoiding leakage and preventing erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

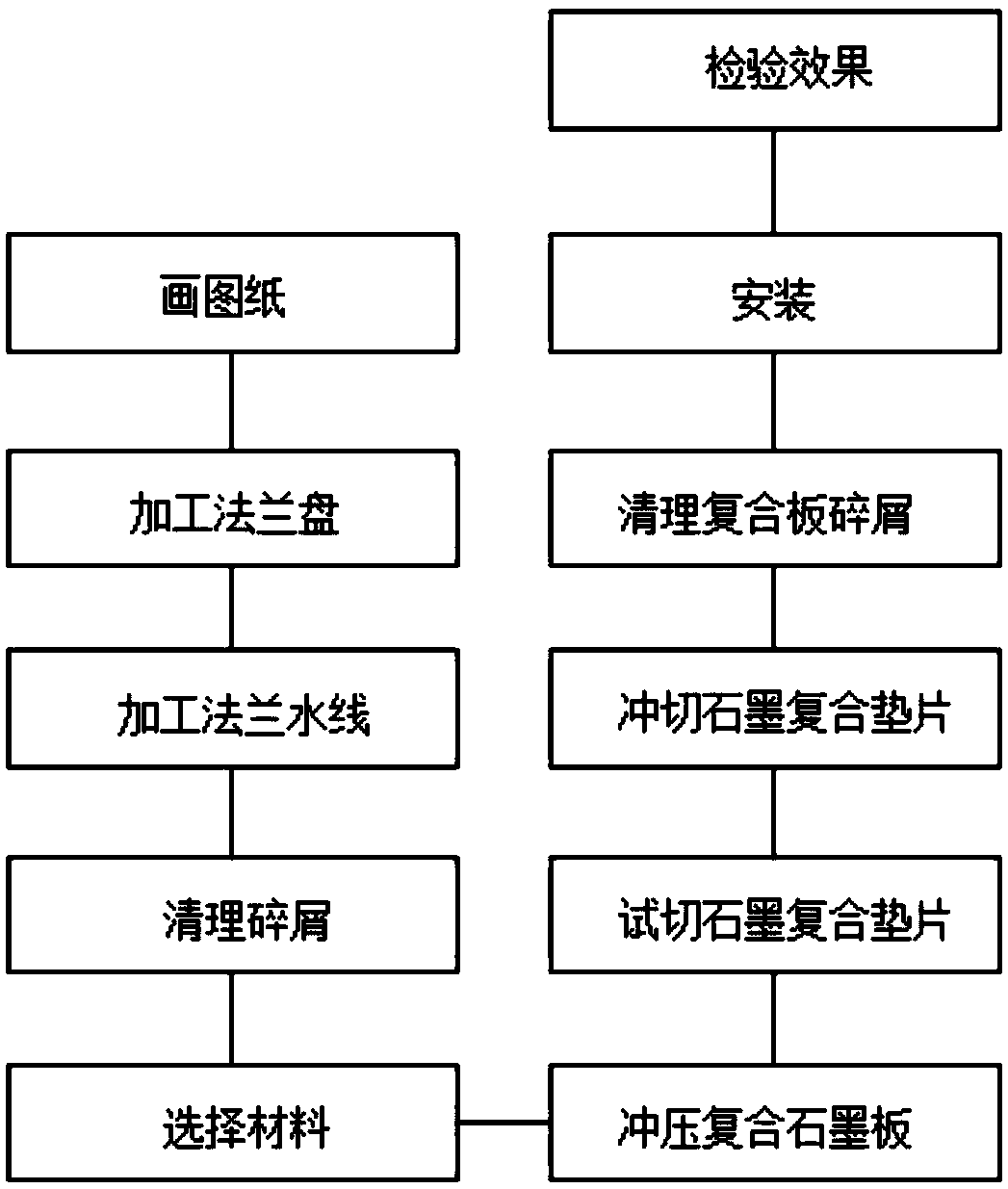

[0025] The invention provides a technical solution: an anti-seepage water treatment process for connecting flanges, comprising the following steps:

[0026] S1: Draw drawings, determine the type of flange waterline, the size of flange waterline and graphite composite gasket, the types of flange waterline include spiral waterline, concentric circle waterline and three waterlines, and select the type according to customer requirements ;

[0027] S2: Processing and manufacturing of flanges. The steps of processing flanges include selecting raw materials, inspecting raw materials, determining the amount of materials used, rough turning, initial polishing, rough forging, re-polishing, fine forging, edge trimming, drilling, heat treatment, Post-polishing, benchmarking, finishing turning, deburring, processing completion, cleaning and inspection;

[0028] S3: Process the waterline of the flange. According to the requirements of the drawing, choose a CNC machine tool with a model of ...

Embodiment 2

[0038] The invention provides a technical solution: an anti-seepage water treatment process for connecting flanges, comprising the following steps:

[0039] S1: Draw drawings, determine the type of flange waterline, the size of flange waterline and asbestos rubber gasket, the types of flange waterline include spiral waterline, concentric circle waterline and three waterlines, and select the type according to customer requirements ;

[0040] S2: Processing and manufacturing of flanges. The steps of processing flanges include selecting raw materials, inspecting raw materials, determining the amount of materials used, rough turning, initial polishing, rough forging, re-polishing, fine forging, edge trimming, drilling, heat treatment, Post-polishing, benchmarking, finishing turning, deburring, processing completion, cleaning and inspection;

[0041] S3: Process the waterline of the flange. According to the requirements of the drawing, choose a CNC machine tool of model Z3050 for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com