Micro-liquidity composite polishing die for large-caliber easily deformed zinc sulfide optical window parts and manufacturing method thereof

An optical window and composite polishing technology, which is applied in the direction of grinding/polishing equipment, manufacturing tools, grinding machine parts, etc., can solve the problems of uneven surface shape accuracy, long processing cycle, and easy deformation of multi-spectral zinc sulfide optical windows. Difficult polishing processing and other problems, to achieve the effect of regular motion trajectory, controllable motion trajectory, and solve the problem of shrinking heat conduction groove and plugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

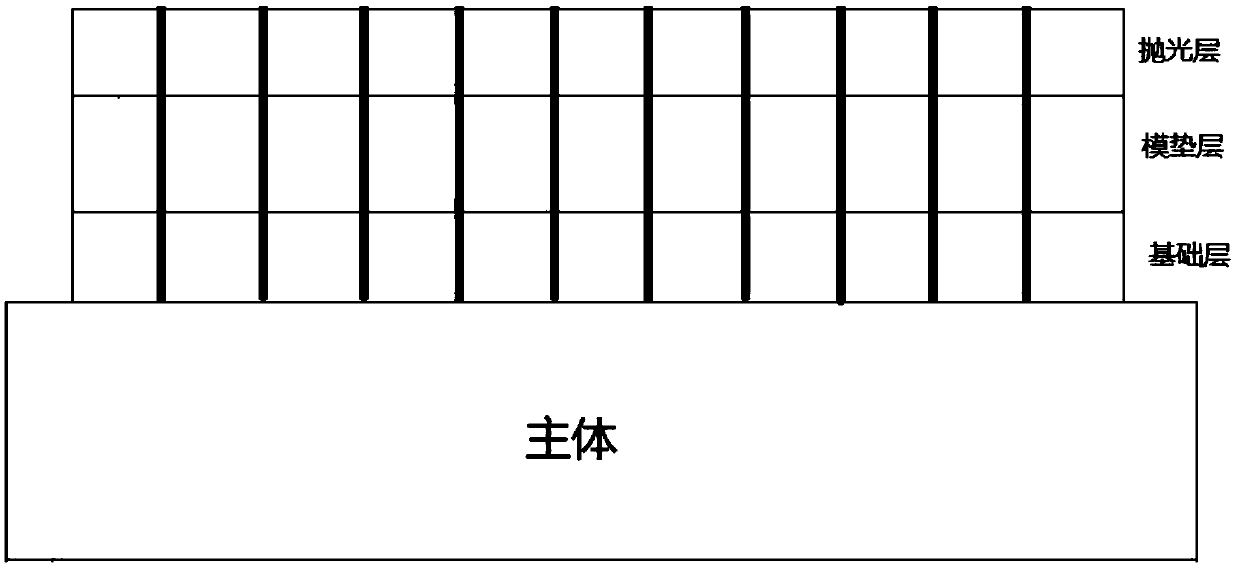

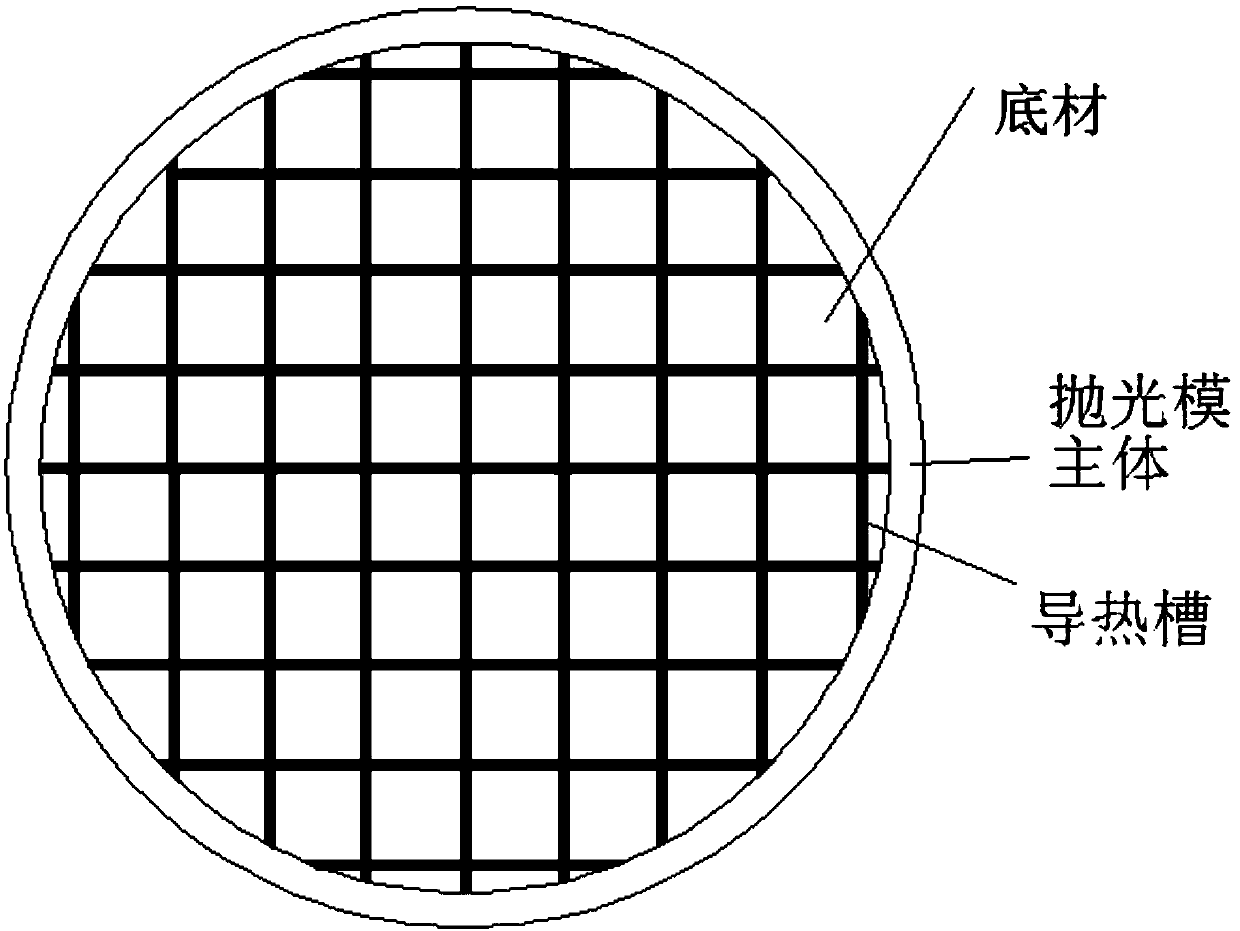

[0038] Such as figure 1 As shown, a microfluidic composite polishing mold for large-diameter deformable zinc sulfide optical window parts above 600mm in this embodiment consists of a polishing mold main body, a base layer, a mold cushion layer and a polishing layer.

[0039] The expansion coefficient of the main body material of the polishing mold is 1.2×10-5 / ℃~0.8×10-6 / ℃, the modulus of elasticity is 120GPa~40GPa; the flatness of the working surface of the main body of the polishing mold is 0.2μm~8μm, and the surface roughness is 0.012μm~1μm; the cross-sectional shape of the main body of the polishing die is circular, the diameter-to-thickness ratio is 8:1-10:1, and the diameter is larger than the diameter or diagonal size of the large-diameter deformable zin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com