Solid foam drainage agent composition, preparation method and application

A technology of composition and foam discharge agent, which is applied to drilling compositions, chemical instruments and methods, etc., can solve the problems of gas well production reduction, stop injection of liquid, difficulty and other problems, and achieve the effect of good acid resistance and good technical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

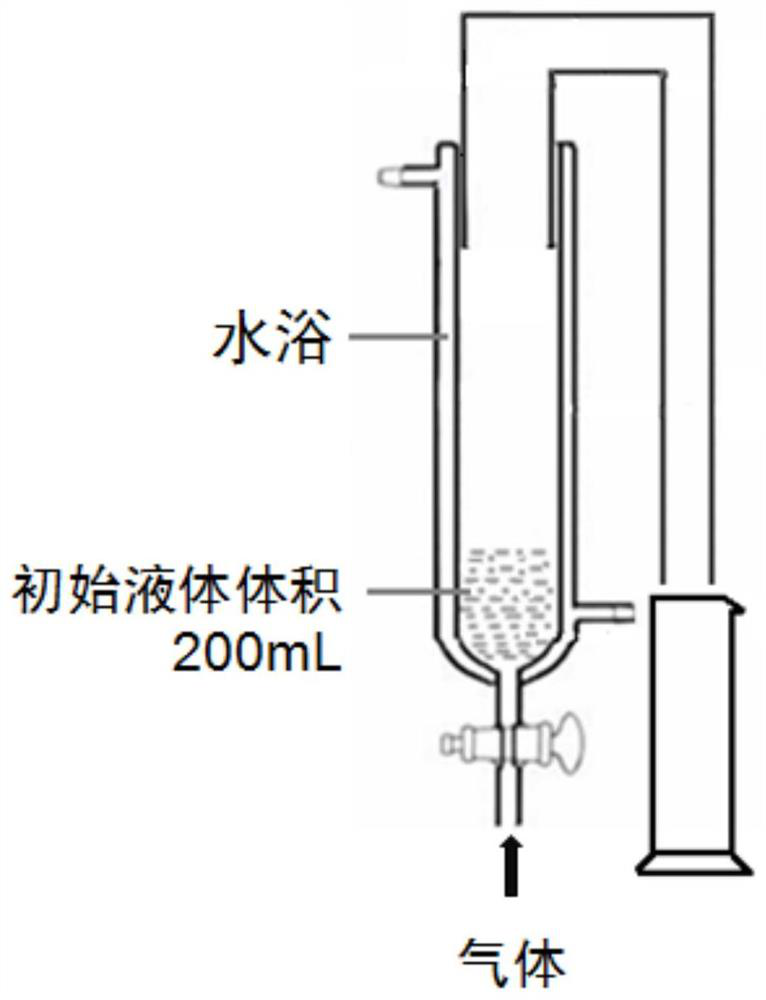

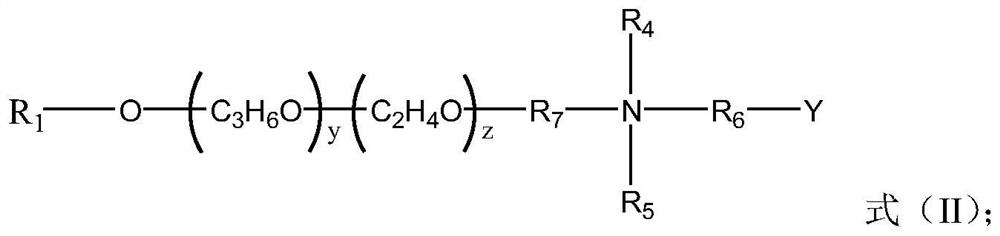

Method used

Image

Examples

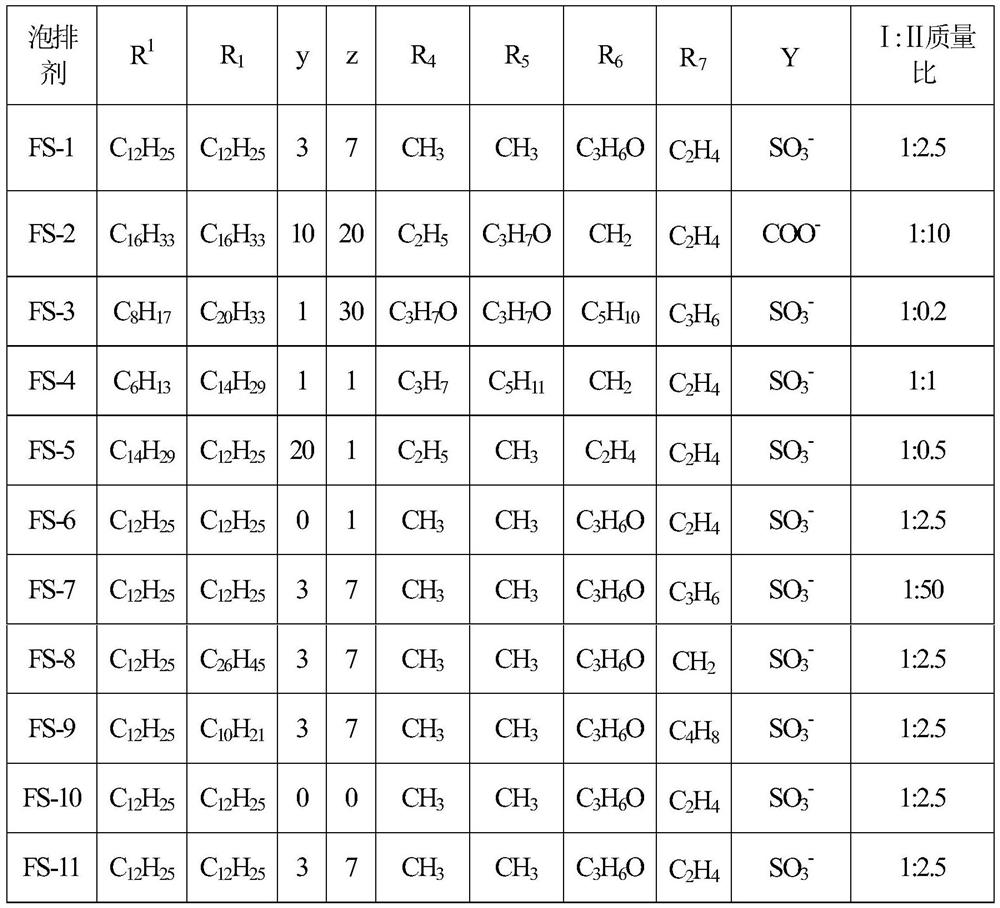

Embodiment 1

[0040] (1) At normal temperature and pressure, mix 10 grams of alkylamine, 25 grams of long-chain polyether nitrogen-containing compound, and 35 grams of sodium sulfate

[0041] homogeneous, a mixture;

[0042] (2) 0.1 gram of polyacrylamide is added with 1 gram of water and stirred until completely dissolved to obtain a binder solution;

[0043] (3) The mixture obtained in step (1) and the binder solution obtained in step (2) were uniformly mixed, and pressed to form a solid foam drainage stick FS-1, whose component structure is shown in Table 1.

Embodiment 2

[0045] (1) Under normal temperature and pressure, 5 grams of alkylamine, 50 grams of long-chain polyether nitrogen-containing compound, 30 grams of sodium sulfate, carbonic acid

[0046] 10 grams of sodium, 30 grams of sodium bicarbonate, and 30 grams of urea were mixed evenly to obtain a mixture;

[0047] (2) Add 0.5 g of polyethylene glycol with 2 g of water and stir until completely dissolved to obtain a binder solution;

[0048] (3) The mixture obtained in step (1) and the binder solution obtained in step (2) were mixed evenly, and pressed to form a solid foam drainage rod FS-2, whose component structure is shown in Table 1.

Embodiment 3

[0050] (1) Under normal temperature and pressure, 50 grams of alkylamine, 10 grams of long-chain polyether nitrogen-containing compound, 10 grams of urea, lemon

[0051] 1 gram of acid, mixed evenly to obtain a mixture;

[0052] (2) Add 0.1 g of starch and 2 g of water and stir until completely dissolved to obtain a binder solution;

[0053] (3) The mixture obtained in step (1) and the binder solution obtained in step (2) were uniformly mixed, and pressed to form a solid foam drainage stick FS-3, whose component structure is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com