Method for synchronously optimizing ammonia injection quantity and ammonia covering rate of diesel engine Urea-SCR system

An optimization method and coverage technology, applied in design optimization/simulation, mechanical equipment, engine components, etc., can solve problems such as inability to build, and achieve the effects of emission optimization, performance optimization, and cost-effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

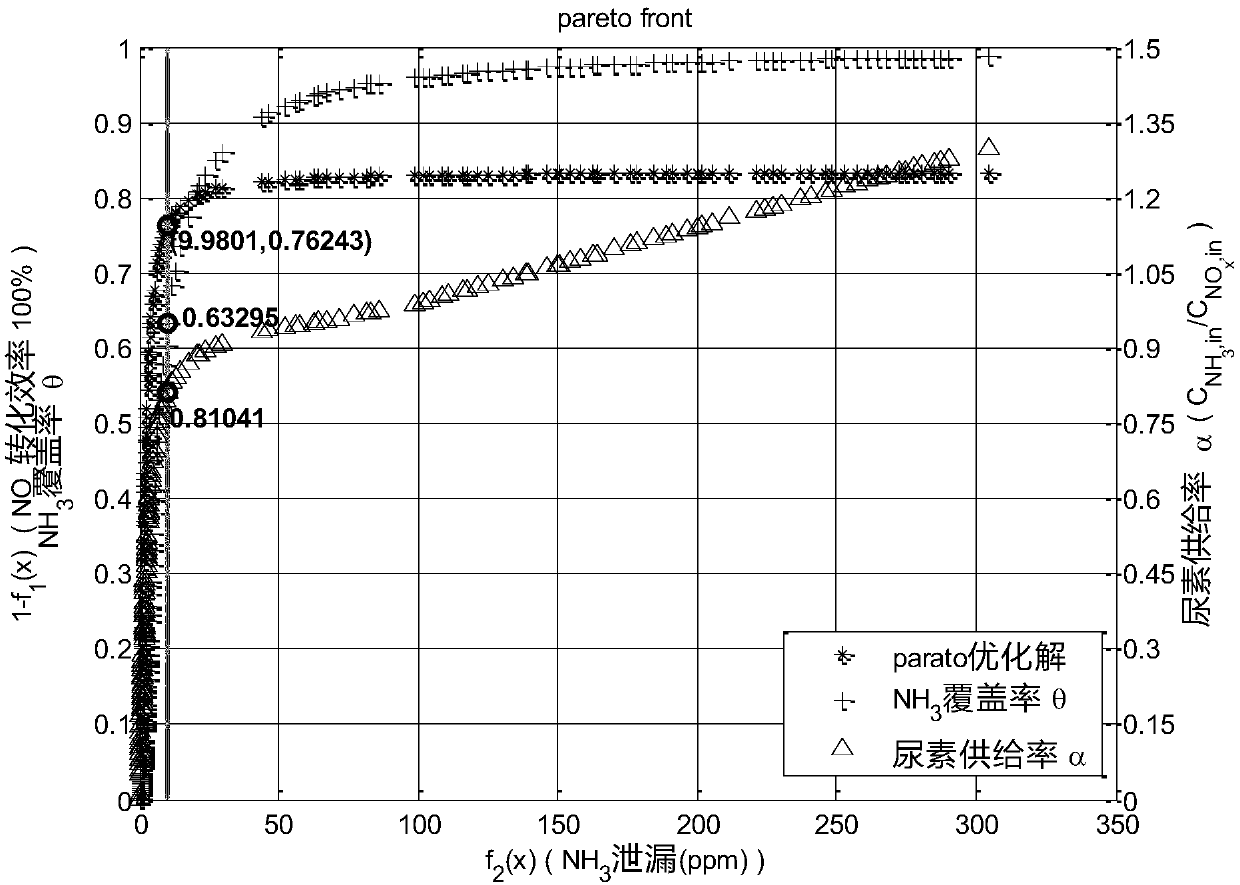

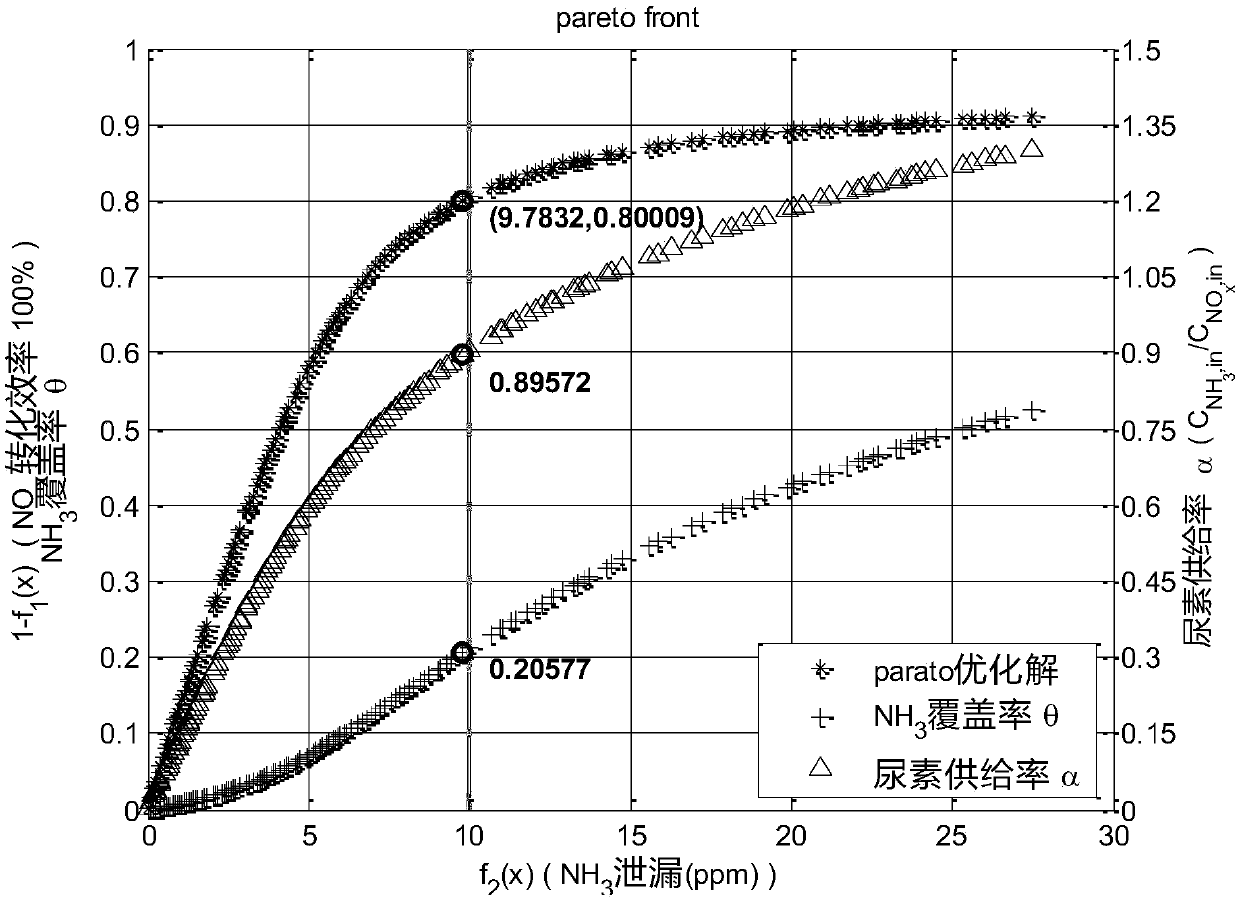

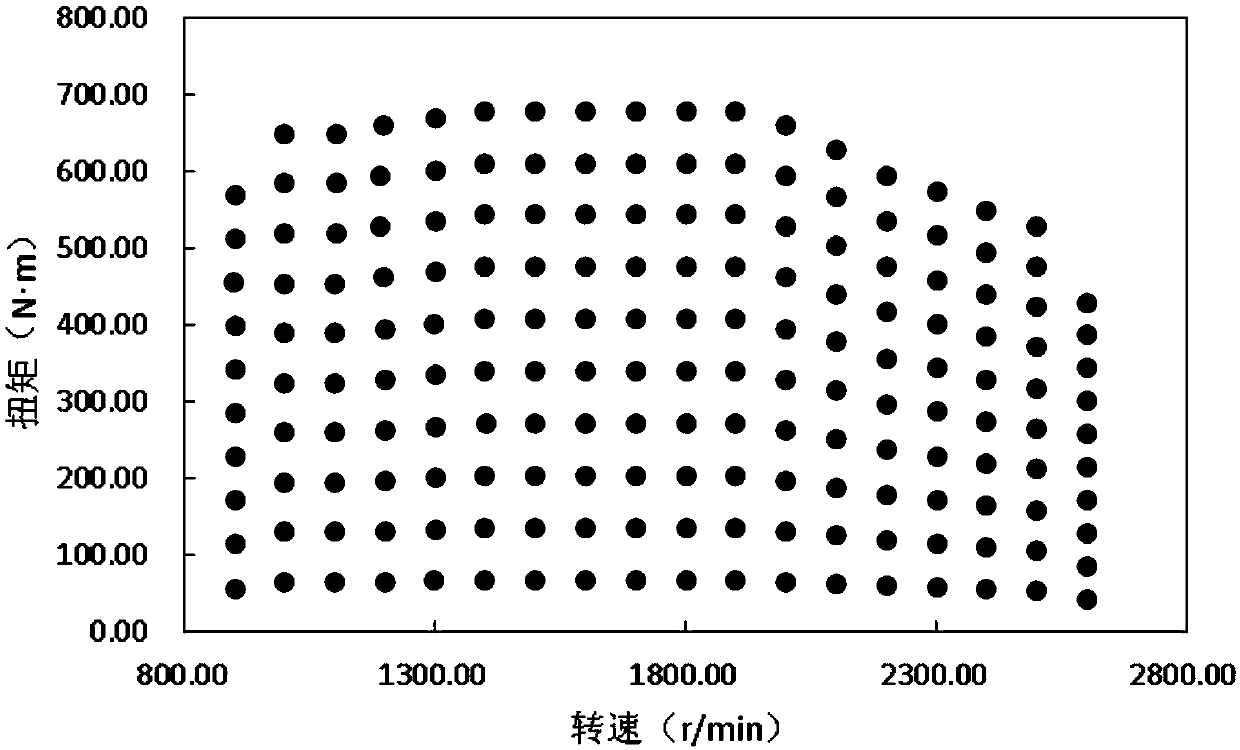

[0049] The specific implementation of the method for synchronously optimizing the ammonia injection amount and ammonia coverage of the diesel engine Urea-SCR system involved in the present invention will be described in detail below in conjunction with the accompanying drawings.

[0050]

[0051] This example is based on the model-based NSGA-II algorithm of the diesel engine Urea-SCR system ammonia injection amount and ammonia coverage synchronous optimization method, which specifically includes the following steps:

[0052] Step 1. Build the SCR system model, including:

[0053] Step 1-1. Establish a Urea-SCR system three-state model based on the four main chemical reactions and reaction rate equations inside the SCR system to predict the NO inside the catalyst x Concentration, NH 3 Concentration and ammonia coverage three state quantities.

[0054] Urea-SCR system catalytic reaction mechanism: The Urea-SCR system for vehicles usually uses 32.5% urea aqueous solution (Tia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com