Steam condensing and recovering system

A steam system and condensation recovery technology, which is applied in steam/steam condensers, refrigerators, refrigeration and liquefaction, etc., can solve the problems of high steam humidity, poor use experience, energy waste, etc., and achieve zero emission and condensation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

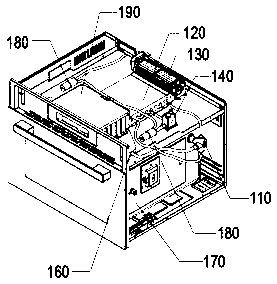

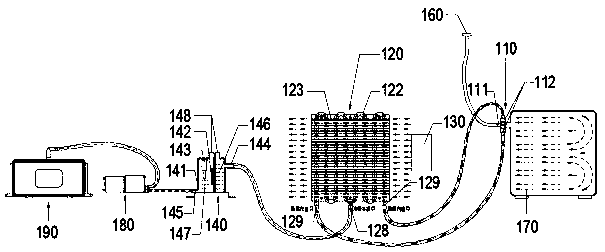

[0039] Please refer to figure 1 and figure 2 , figure 1Show the use state diagram of the condensate recovery steam system, figure 2 Schematic showing the condensate recovery vapor system. The condensing steam recovery system includes a switching orienter 110 , a condensing device 120 , a cold power source 130 and a purified and filtered water storage tank 140 . The switching orienter 110 has a three-way port and is installed in the cooking inner cavity 170. The one-way port 111 is connected to the ventilation interface seat 160, and the two-way port 112 is connected to the condensing device 120 for condensing saturated waste steam. The purified and filtered water storage tank 140 is also connected to the condensing device 120 . The cold power source 130 is used to provide cold air to the condensing device 120 . It should be noted that the switching orienter 110 has or can be two-way ports or other number of ports more than two-way. As long as there are ports connected t...

no. 2 example

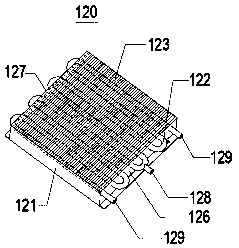

[0047] Please refer to Figure 8-Figure 12 , the present embodiment provides a condensing recovery steam system, which is substantially the same as the condensing recovery steam system in the first embodiment, the difference between the two lies in the structure of the condensing device 120 in this embodiment.

[0048] Please continue to refer to Figure 8-Figure 10 , the condensation device 120 includes a refrigerator generating source 221 , a heat conducting plate 222 , an NP type semiconductor cold chip 223 , a cold conducting plate 224 , a condensation box 225 and a silicone sealing ring 226 . The refrigerator generating source 221 , heat conduction fins 222 , NP type semiconductor cold chips 223 , and cold conduction fins 224 are arranged sequentially from top to bottom. In this embodiment, the refrigerator generating source 221 is an axial flow cooling fan, please refer to Figure 11 , is a schematic diagram of the installation of the condensing device 120 in this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com