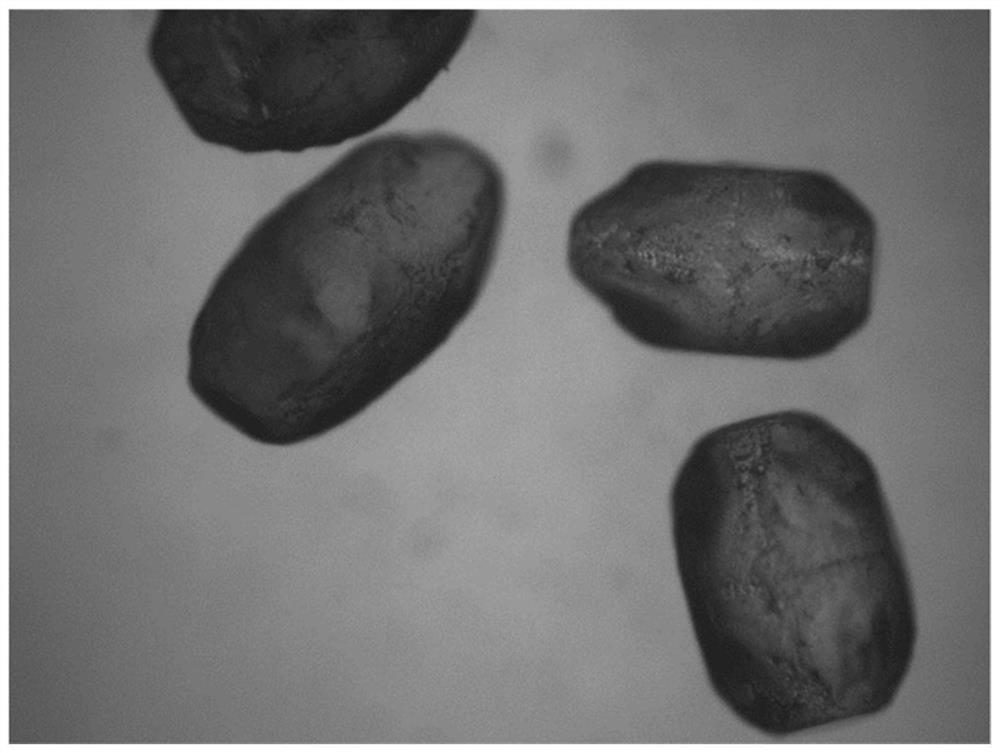

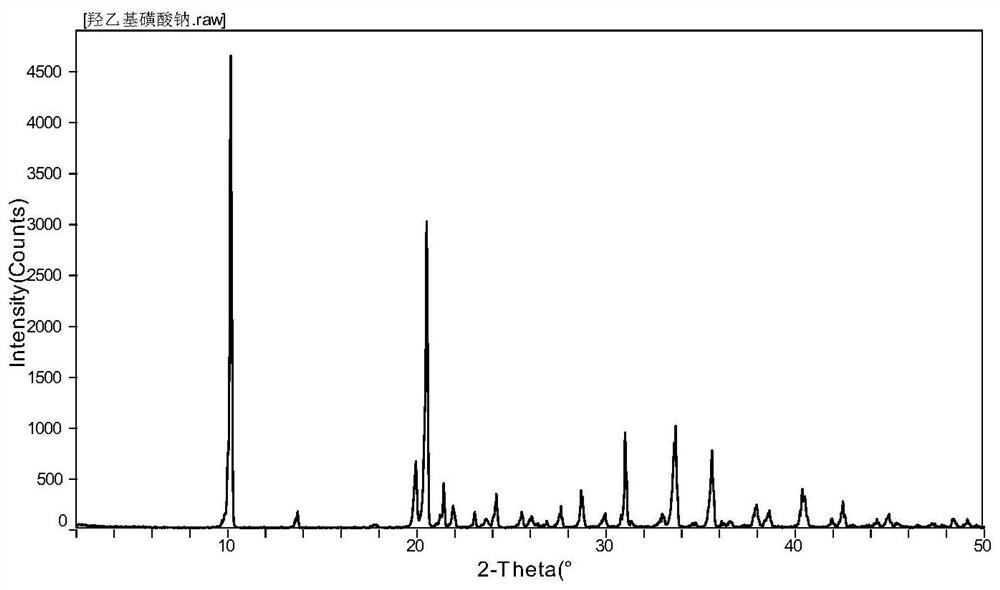

A kind of sodium isethionate ellipsoidal crystal and preparation method thereof

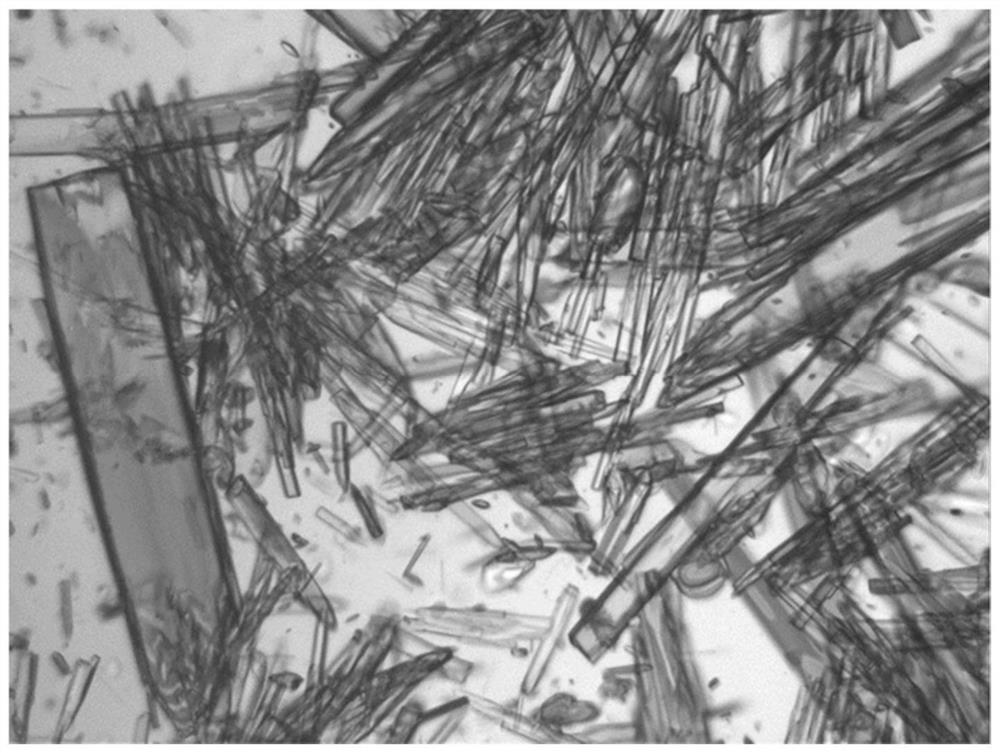

A sodium isethionate, ellipsoid technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as uneven distribution, poor formulation performance, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A suspension of sodium isethionate with a concentration of 40% in water was prepared, 500 ppm of gallic acid was added thereto, the temperature was raised to 85° C., and the system was stirred to dissolve. The pressure of the system was controlled by a diaphragm vacuum pump, and gradually decreased linearly from 0.1 MPa to 0.01 MPa within 1 hour, and the system was concentrated to 56%. Stop stirring and grow the crystal for 1h. Then, the temperature was gradually and linearly lowered to 25° C. in a constant temperature bath at a cooling rate of 6° C. / h. After centrifuging, washing and spray-drying the crystalline slurry liquid, ellipsoidal sodium isethionate crystals are obtained. The main particle size of the product is 520 μm, and the bulk density is 1.10 g / mL.

Embodiment 2

[0036] Prepare a suspension of sodium isethionate with a concentration of 50% in water, add 10,000 ppm of gallic acid therein, heat up to 95° C., and stir to dissolve the system. The pressure of the system was controlled by a diaphragm vacuum pump, and gradually decreased linearly from 0.1 MPa to 0.01 MPa within 4 hours, and the system was concentrated to 63%. Stop stirring and grow the crystal for 3h. Then, the temperature was gradually and linearly lowered to 15° C. in a constant temperature bath at a cooling rate of 30° C. / h. After centrifuging, washing and spray-drying the crystalline slurry liquid, ellipsoidal sodium isethionate crystals are obtained. The main particle size of the product is 708 μm, and the bulk density is 1.31 g / mL.

Embodiment 3

[0038] A suspension of sodium isethionate with a concentration of 42% in water was prepared, 2000 ppm of gallic acid was added thereto, the temperature was raised to 90° C., and the system was stirred to dissolve. The pressure of the system was controlled by a diaphragm vacuum pump, and gradually decreased linearly from 0.1 MPa to 0.01 MPa within 2 hours, and the system was concentrated to 58%. Stop stirring and grow the crystal for 2h. Then, the temperature was gradually and linearly lowered to 20° C. in a constant temperature bath at a cooling rate of 10° C. / h. After centrifuging, washing and spray-drying the crystalline slurry liquid, ellipsoidal sodium isethionate crystals are obtained. The main particle size of the product is 572 μm, and the bulk density is 1.14 g / mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com