High efficiency liquid chromatograph analysis method for sodium isethionate

A technology of high performance liquid chromatography and sodium isethionate, which is applied in the field of high performance liquid chromatography analysis of sodium isethionate, can solve the problem that the use of ion chromatography is not as popular as that of high performance liquid chromatography, there is no standard release, and there are no articles Reporting and other issues, to achieve the effect of high sensitivity, fast speed and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

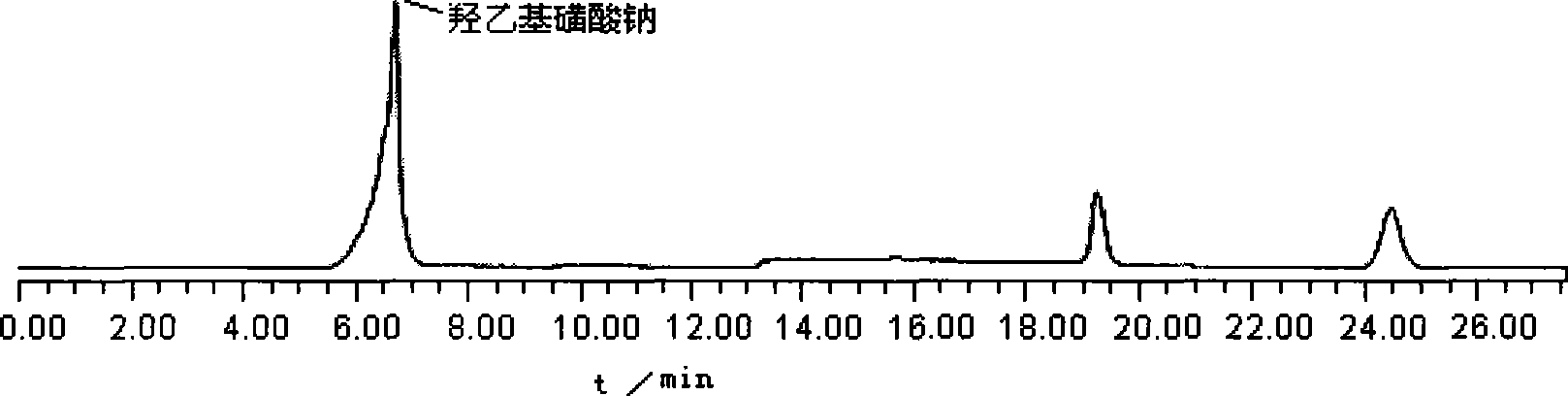

Embodiment 1

[0024] laboratory apparatus:

[0025] WATERS1525 high performance liquid chromatograph (Waters, USA);

[0026] Waters2420 type evaporative light scattering detector (Waters, USA);

[0027] Empower chromatography workstation;

[0028] Ultrasonic cleaner, Shanghai Kedao Ultrasonic Instrument Co., Ltd.;

[0029] JA1004 electronic balance (1 / 10000 balance) (Shanghai Precision Scientific Instrument Co., Ltd.);

[0030] Dionex OnGuard IIRP pre-treatment pre-column (Dionex, USA);

[0031] Dionex 500 ion chromatograph (Dionex, USA);

[0032] DionexAG11-AS11-HC separation column (Dionex, USA);

[0033] Dionex conductivity detector (Dionex, USA).

[0034] Chromatographic conditions:

[0035] Chromatographic column: 250mm×4.6mm(id) stainless steel column, Lichrospher-5μm-C 18 filler;

[0036] Mobile phase composition volume ratio: methanol: ultrapure water = 100:0;

[0037] Flow rate: 0.4mL / min;

[0038] Column temperature: 25°C;

[0039] Evaporative light scattering detector...

Embodiment 2

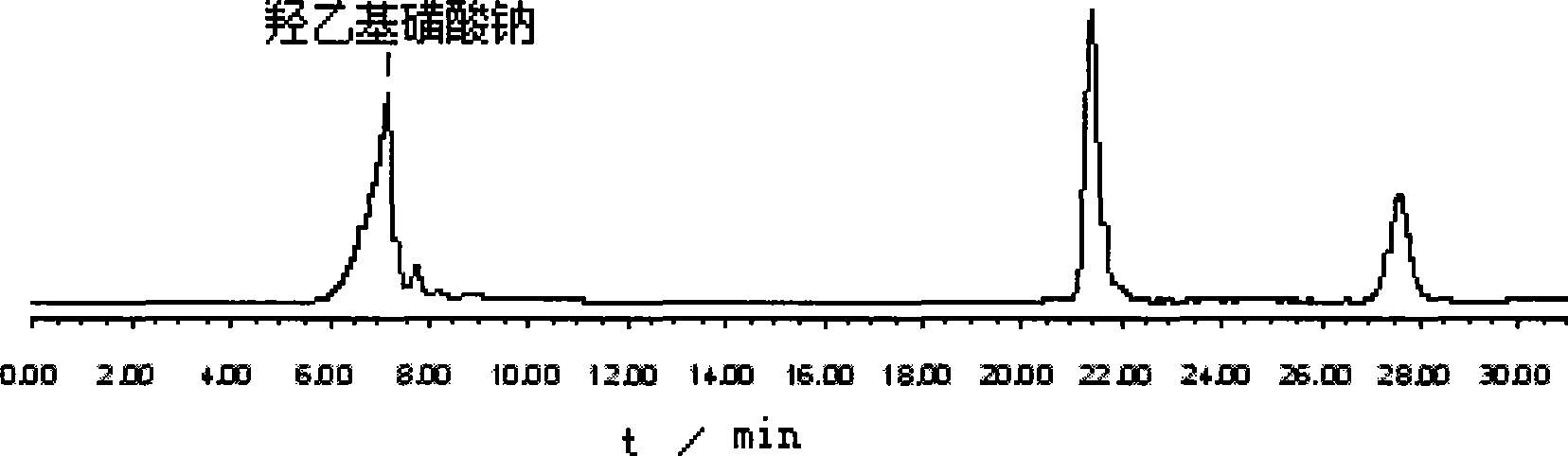

[0076] Chromatographic conditions:

[0077] Chromatographic column: 250mm×4.6mm(id) stainless steel column, Lichrospher-5μm-C 18 filler;

[0078] Mobile phase composition volume ratio: methanol: ultrapure water = 100:0;

[0079] Flow rate: 0.8mL / min;

[0080] Column temperature: 25°C;

[0081] Evaporative light scattering detector;

[0082] Spray chamber level of the detector: 60%;

[0083] Drift tube temperature: 40°C;

[0084] Nitrogen pressure: 20psi;

[0085] The injection volume was 20 μL.

[0086] All the other implementations are the same as in Example 1.

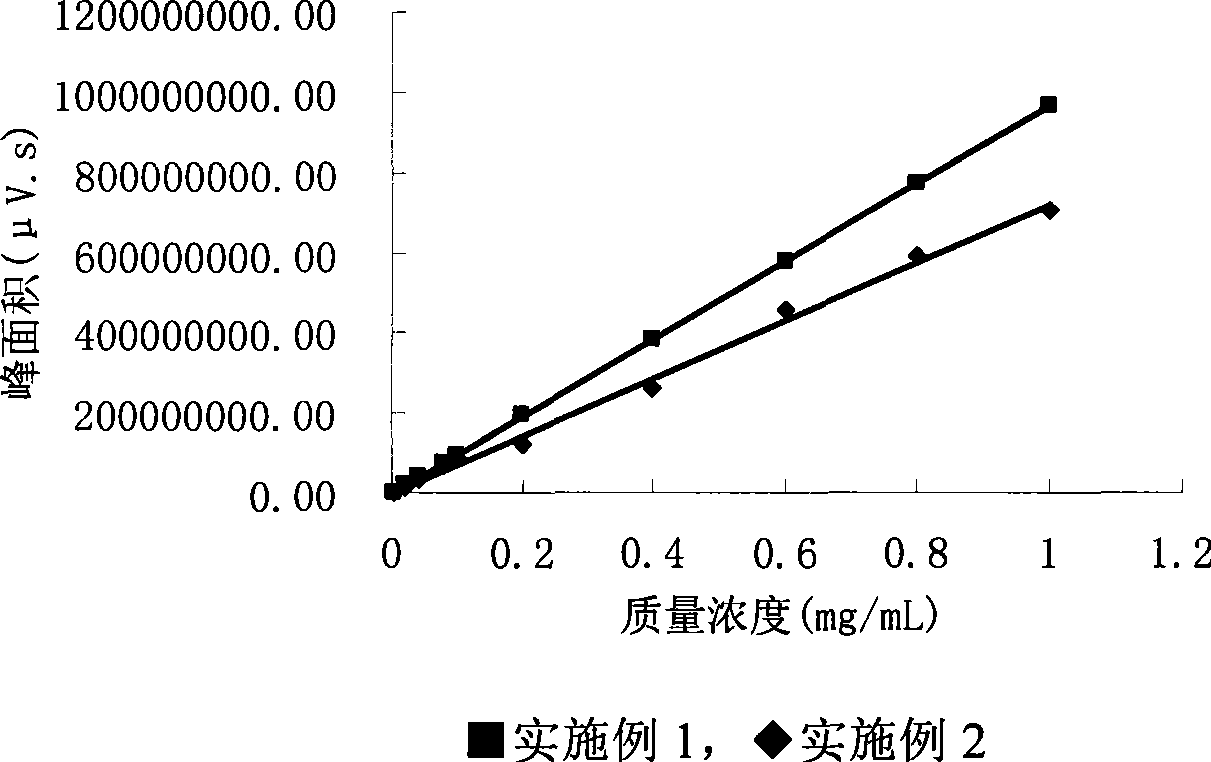

[0087] 1. Standard curve and linear relationship

[0088] Precisely draw the SI standard solution in Step 2 of Example 1, place it in a volumetric flask, and constant volume with methanol to obtain mass concentrations of 0.004mg / mL, 0.02mg / mL, 0.04mg / mL, 0.08mg / mL, 0.1mg SI standard solutions of / mL, 0.2mg / mL, 0.4mg / mL, 0.6mg / mL, 0.8mg / mL and 1.0mg / mL were measured according to the above chromatographic con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com