Method for preparing N-sodium methyl taurate

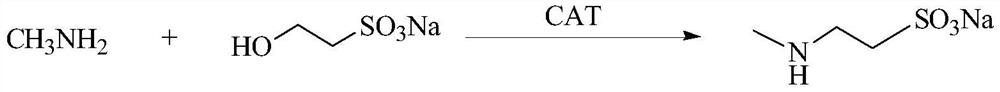

A technology of sodium methyl taurate and sodium isethionate, applied in the direction of sulfonate preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of low conversion rate, High cost, limited sources of raw materials, etc., to achieve high selectivity, reduce industrialization costs, and improve raw material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of Catalyst A:

[0032] Dissolve 10.0g of ammonium metavanadate in 50ml of 4.5wt% oxalic acid solution, stir until dissolved; then add 3.0g of TiO 2 Powder, stir well, stand at room temperature for 24 hours, filter under reduced pressure, wash the filter cake with 20ml deionized water for 3 times, dry in an oven at 90°C for 12 hours, then place in a muffle furnace at a heating rate of 3°C / min Raise from room temperature to 280°C, keep the temperature constant for 3 hours, then reach 550°C at a rate of 3°C / min, keep the temperature constant for 4 hours, take it out after cooling, grind and sieve the (80-120) mesh part to get V 2 o 5 / TiO 2 Powder.

[0033] Dissolve 15.0g of ammonium tungstate in 50ml of 4.5wt% oxalic acid solution, stir until dissolved; then add 3.0g of V 2 o 5 / TiO 2 Powder, stir well, stand at room temperature for 24 hours, filter under reduced pressure, wash the filter cake with 20ml deionized water for 3 times, dry in an oven at 90°...

Embodiment 2

[0040] Add 486.6g of 30.4wt% sodium isethionate solution into the reactor, add 0.75g of catalyst A, replace with N2, add 34.1g of methylamine to the system, control the temperature at 35°C, and fill the system with N2, The pressure in the system was controlled at 0.2MpaG, and the temperature was lowered after 150min of heat preservation reaction to take a sample. The mass of sodium N-methyl taurate was detected by LC to be 152.9g. The conversion rate of this reaction was 96.7%, and the selectivity was 98.2%.

[0041] 1H NMR (400MHz, D2O) δ3.55(t, J=7.1Hz, 2H), 3.24(s, 3H), 3.13(t, J=7.1Hz, 2H).

Embodiment 3

[0043] Add 378.3g of 46.99wt% sodium isethionate solution into the reactor, add 1.778g of catalyst A, replace with N2, add 123.0g of methylamine to the system, control the temperature at 35°C, and fill the system with N2, The pressure in the system was controlled at 7.8MpaG, and the temperature was lowered to take samples after the heat preservation reaction was performed for 285 minutes.

[0044] The mass of sodium N-methyl taurate detected by LC was 118.1 g. The conversion rate of this reaction was 73.2%, and the selectivity was 83.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com