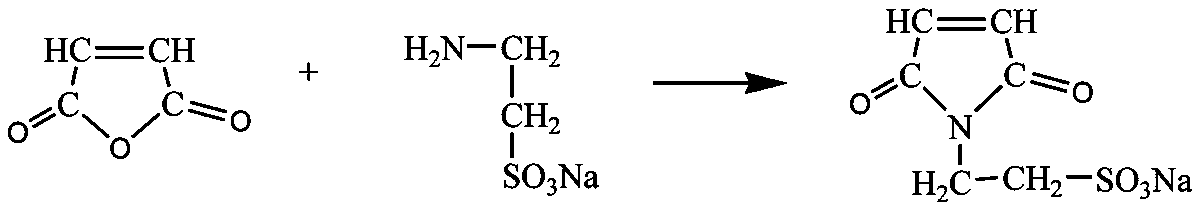

N-maleimide-N-sodium isethionate and method for preparing same

A technology of maleimide and sodium ethylsulfonate, applied in the field of material preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

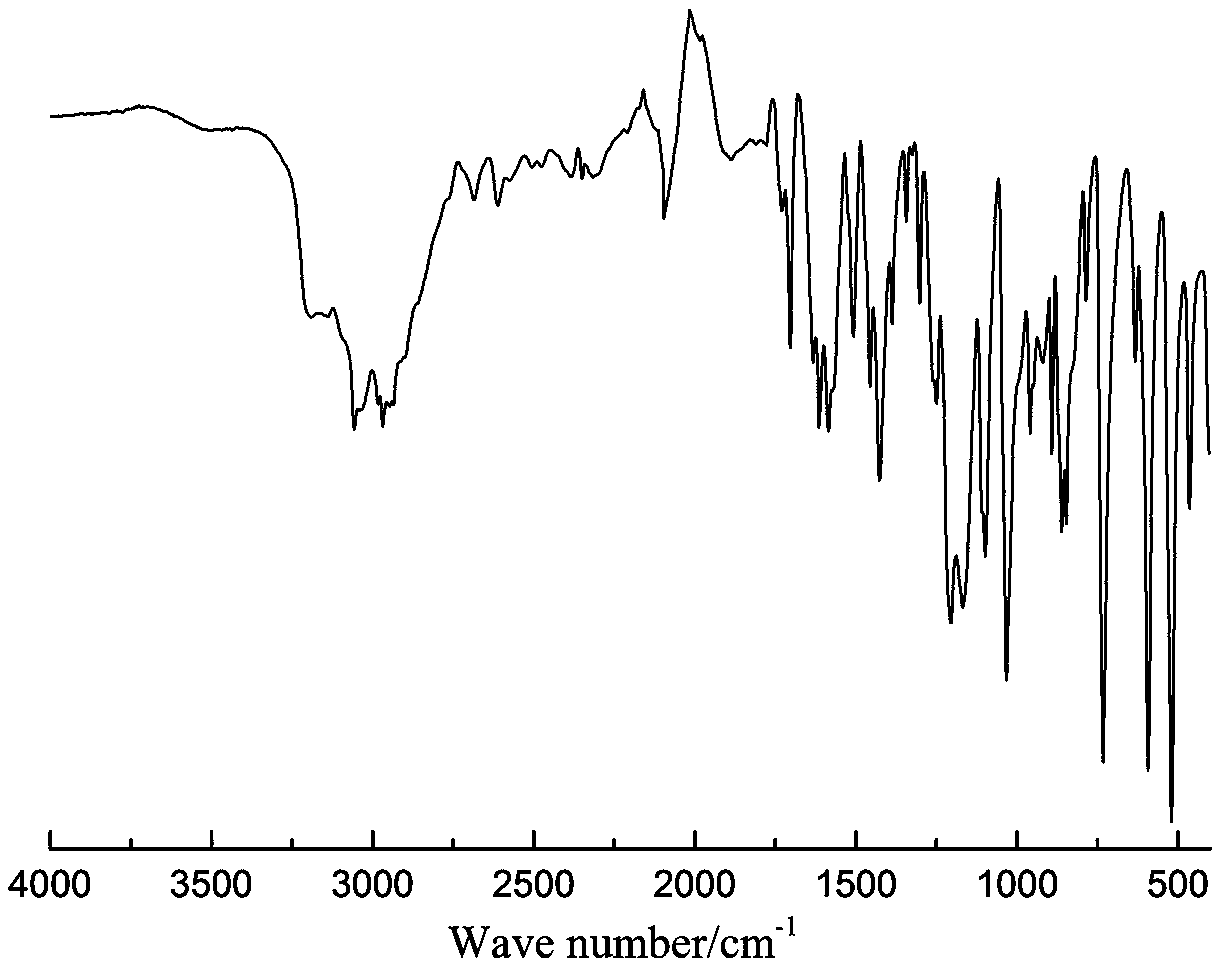

Method used

Image

Examples

preparation example Construction

[0025] A kind of preparation method of above-mentioned N-maleimide-N-sodium ethylsulfonate, the steps are as follows:

[0026] Put the ethanol solution of 10wt%-30wt% maleic anhydride in the reactor, heat slowly at a heating rate of 2°C / min, when the temperature rises to 60-70°C, add 10wt%-30wt% 2-aminoethyl The sodium sulfonate aqueous solution and the ethanol solution of 10wt%-30wt% catalyst are slowly dropped into the reactor at the same time, the dropping time is 1-2h, the reaction temperature is 60-70°C; the reaction is 6-8h. After the reaction, excessive ethanol was added to the reactor, and the product was precipitated from the system, and filtered, washed and dried to obtain refined N-maleimide-N-sodium ethylsulfonate; 2- The mass ratio of sodium amino ethyl sulfonate, maleic anhydride and catalyst is 1:0.8-1.2:0.2-0.5.

[0027] In the step, the catalyst is one or both of triethanolamine, sodium hydroxide and potassium hydroxide.

Embodiment 1

[0029] N-maleimide-N-sodium ethylsulfonate is made from the following raw materials in parts by weight:

[0030] Sodium 2-aminoethylsulfonate 10 parts

[0031] 10 parts maleic anhydride

[0032] 10 parts of triethanolamine.

[0033] The preparation method of above-mentioned N-maleimide-N-ethylsulfonate sodium, the steps are as follows:

[0034] Dissolve 10 g of maleic anhydride in 90 g of ethanol, place it in a reactor, and heat it slowly at a heating rate of 2° C. / min. When the temperature rises to 60°C, dissolve 8g of sodium 2-aminoethylsulfonate in 72g of aqueous solution and 2g of triethanolamine in 18g of ethanol solution and slowly drop them into the reactor at the same time, the dropping time is 1h, and the reaction temperature is 60°C ; Reaction 6h. After the reaction is finished, excess ethanol is added into the reactor, and the product is precipitated from the system, filtered, washed and dried to obtain refined N-maleimide-N-ethylsulfonate sodium.

Embodiment 2

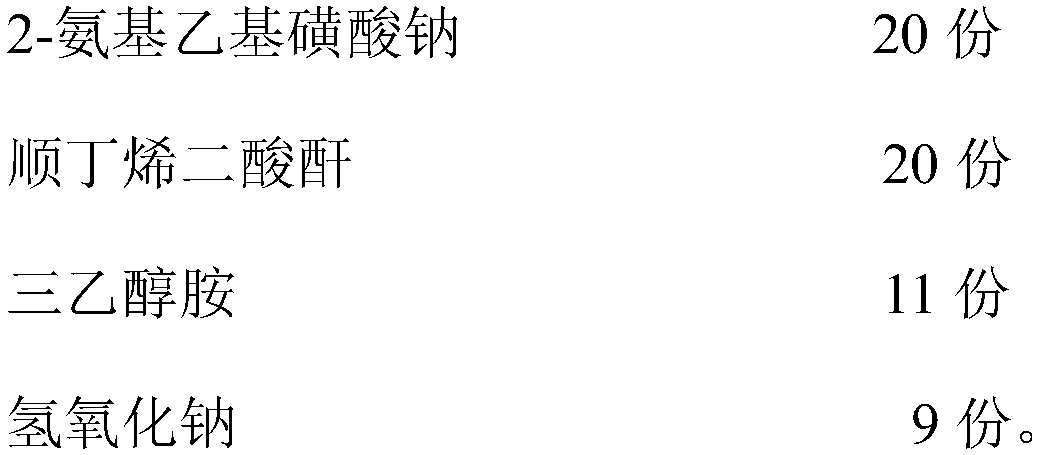

[0036] N-maleimide-N-sodium ethylsulfonate is made from the following raw materials in parts by weight:

[0037] Sodium 2-aminoethylsulfonate 20 parts

[0038] 20 parts maleic anhydride

[0039] 20 parts of sodium hydroxide.

[0040] The preparation method of above-mentioned N-maleimide-N-ethylsulfonate sodium, the steps are as follows:

[0041] Dissolve 20g of maleic anhydride in 80g of ethanol, place it in a reactor, and heat it slowly at a heating rate of 2°C / min. When the temperature rises to 65°C, 20g of sodium 2-aminoethylsulfonate dissolved in 80g of aqueous solution and 8g of sodium hydroxide dissolved in 32g of ethanol solution are slowly dropped into the reactor at the same time, the time of dropping is 1.5h, and the reaction temperature is 65°C; Reaction for 7h. After the reaction is finished, excess ethanol is added into the reactor, and the product is precipitated from the system, filtered, washed and dried to obtain refined N-maleimide-N-ethylsulfonate sodium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com