Copper-based surface porous structure and manufacturing method thereof

A technology with porous surface and porous structure, applied in the field of advanced manufacturing, can solve the problems of large pore size, poor pore distribution uniformity and consistency, etc., and achieve the effect of uniform pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

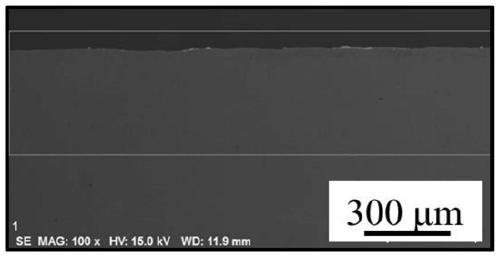

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with specific examples, but the present invention is not limited to the following examples.

[0026] In order to solve the problems of large pore size, poor pore distribution uniformity and poor consistency of the metal surface porous structure prepared by the traditional method, the present invention proposes a copper-based surface porous structure and a manufacturing method thereof.

[0027] Laser alloying adds alloying materials to the surface of the substrate, and uses a high-energy-density laser beam to melt and rapidly solidify it simultaneously with the surface of the substrate, thereby forming a metallurgically bonded surface coating on the surface of the substrate. By laser alloying, a copper-manganese alloy layer that is metallurgically bonded to the copper substrate can be prepared. On this basis, combined with the dealloying technology, the manganese element in the copper-manganes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com