Fabric skewing improvement method

A fabric and weft skew technology, applied in the field of textile manufacturing, can solve problems such as inaccurate bundle angles, long equipment stop times, and difficulty in reaching them, so as to reduce the process of connecting bundles, ensure quality and appearance, and facilitate post-processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

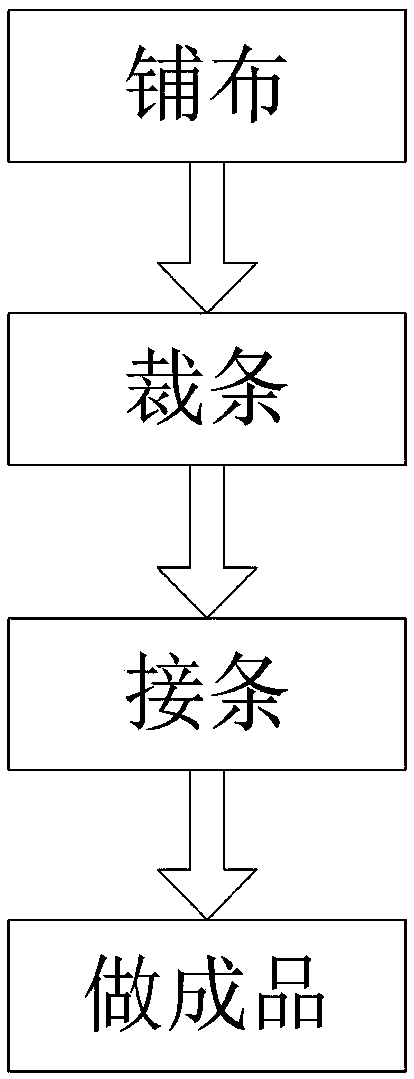

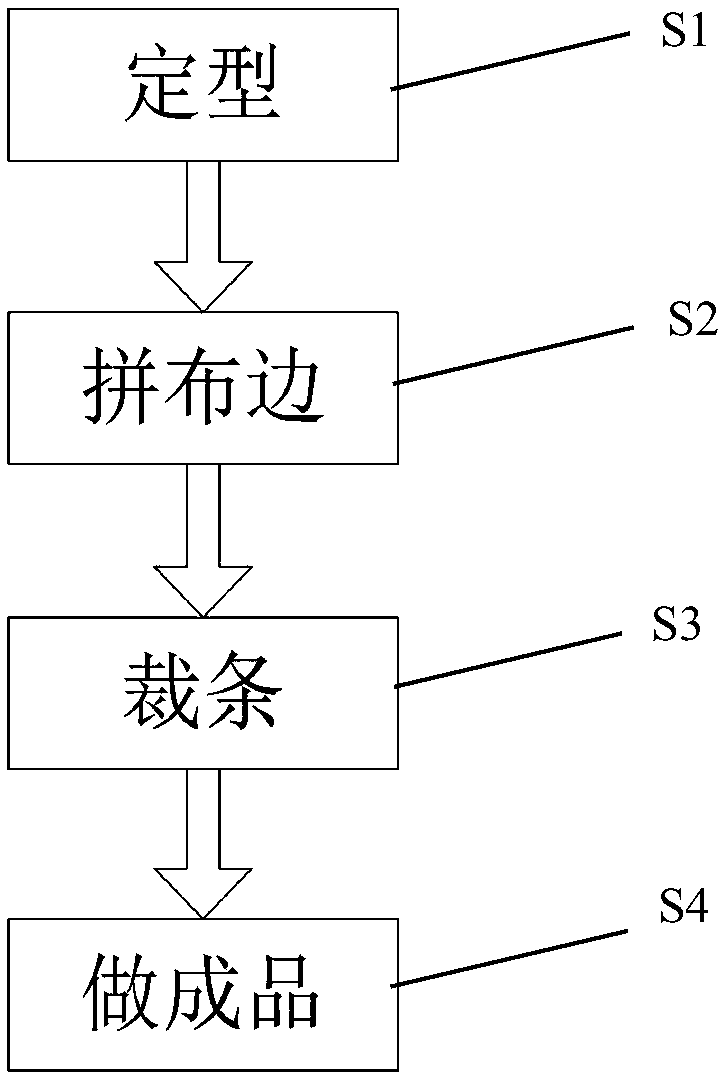

Method used

Image

Examples

Embodiment 2

[0034] The method for improving the weft weft of the fabric in this embodiment is basically the same as that in Embodiment 1, the difference being that the shaping operation in this embodiment is to use coating equipment to coat rice milk on the fabric and then dry it.

Embodiment 3

[0036] The method for improving the weft skew of the fabric in this embodiment is basically the same as that in Embodiment 1, the difference is that the raw material used in the setting operation in this embodiment is slurry made from flour or starch.

[0037] According to the invention, the materials are selected and shaped according to the characteristics of the materials, which is simple and environmentally friendly, and has high operating reliability, which can ensure the quality and appearance of the products; It is also very convenient; adopting the method of the present invention can reduce the operation of binding strips, reduce the cost of supplementary materials, improve production efficiency, and reduce the cost of comprehensive production; the method has wide applicability and can be applied to other products that need to be shaped Cloth can produce better social benefits and greater economic benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com