Reflective near-ultraviolet cut-off diffusion film

A near-ultraviolet, reflective technology, applied in the direction of diffusion elements, optics, instruments, etc., can solve the problems of high equipment investment, complex process, high cost, etc., and achieve the effect of high light transmittance, simple manufacturing process and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be further described below in combination with specific embodiments.

[0024] 1. First put the tin foil on the flat iron plate and put it in the oven, bake it to 70-90°C (the actual normal is 75-80°C);

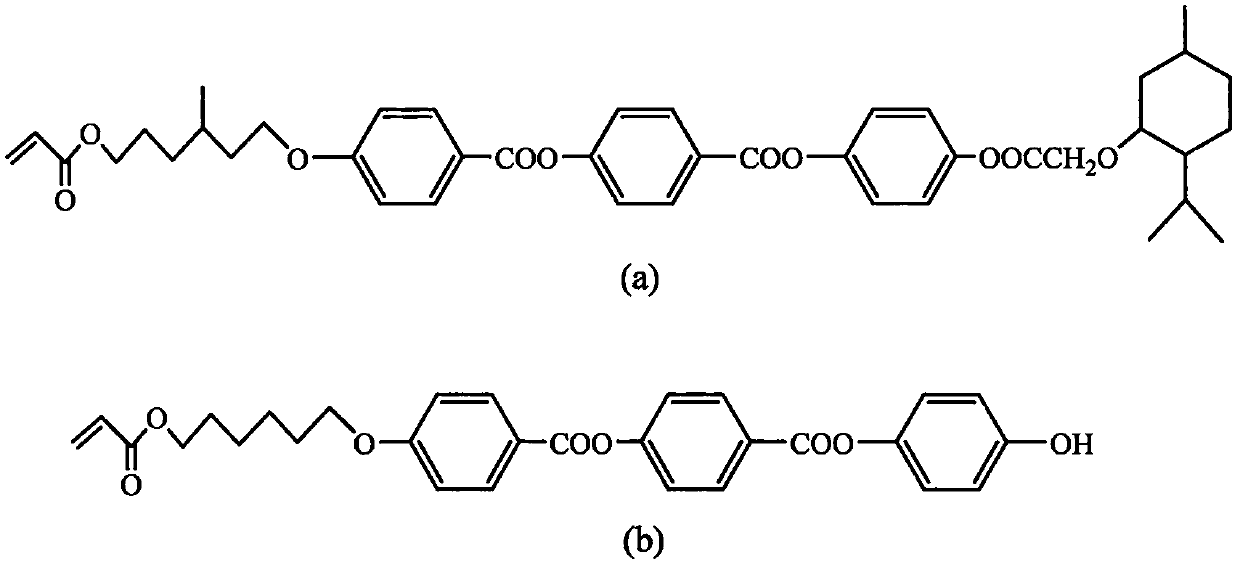

[0025] 2. Get 10 parts of 5% nitroaniline next, 10 parts of chiral polymerizable monomer (a), 10 parts of achiral polymerizable monomer (b), PMMA resin microsphere (average particle diameter is 10 microns) 20 parts 0.6 part of initiator perketene silane acetal, 0.1 part of leveling agent Solvesso150, 20 parts of cyclohexanone, 100 parts of toluene, 0.2 part of curing agent DACH, stir and mix the above materials evenly to obtain a near-ultraviolet cut-off polymer Coating solution, use RDS4# wire rod (wet film gap 10μm), control the wet film thickness to 2-20μm and evenly coat it on 50μm PET without any HC or primer;

[0026] 3. After the coating is completed, put the wet film on the tin foil or iron plate of the oven,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com