Drive substrate and display device

A technology for driving substrates and display devices, applied in the field of driving substrates and display devices, can solve problems such as high power loss, increased parasitic capacitance, and high current intolerance, so as to improve signal delay and high power consumption, and minimize parasitic capacitance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

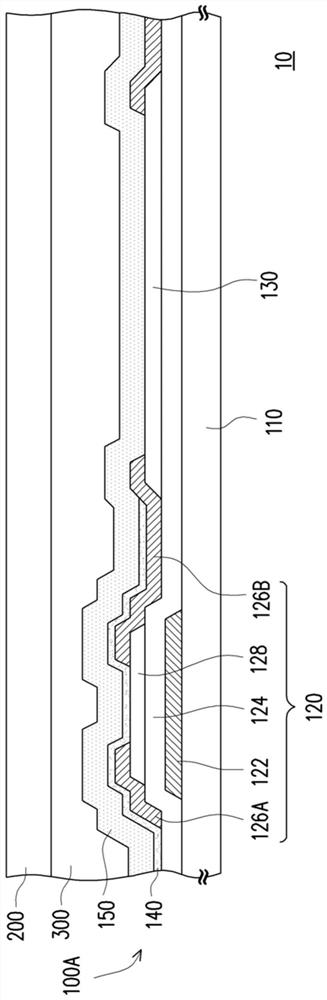

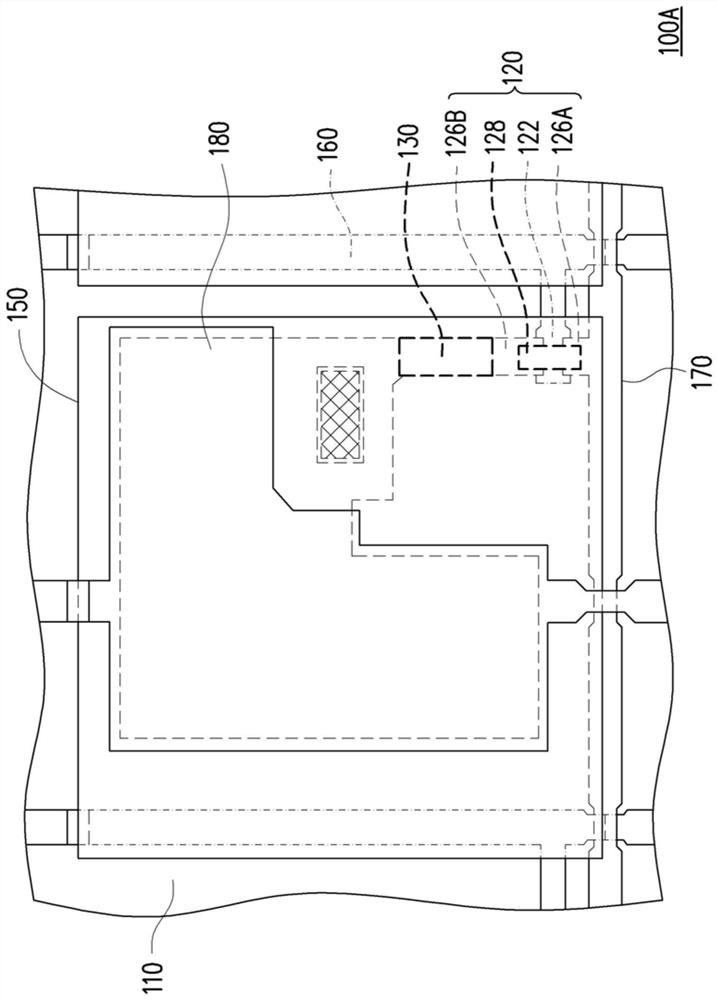

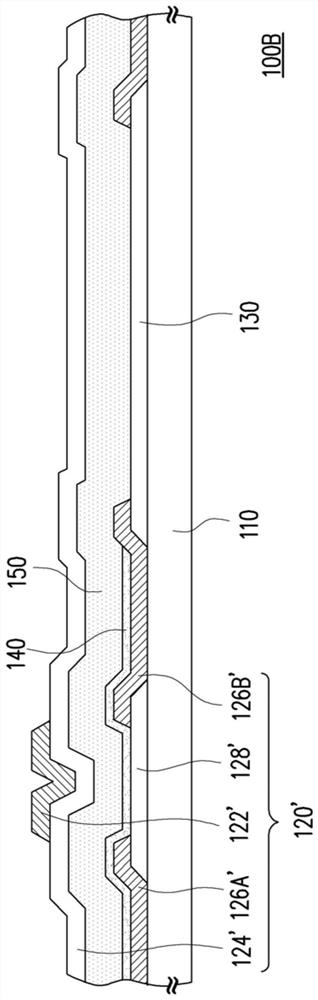

[0046] Figure 1A A schematic partial cross-sectional view of a display device according to an embodiment of the present invention is shown. Figure 1B shown as Figure 1A The schematic top view of the driving substrate. Please refer to Figure 1A , the display device 10 of this embodiment includes a driving substrate 100A and a display medium 200 , wherein the display medium 200 is disposed on the driving substrate 100A. Here, the display medium 200 is, for example, an electrophoretic display film or an electrowetting display film, but is not limited thereto. Such as Figure 1A As shown, the display device 10 of this embodiment may further include a planarization layer 300 disposed between the driving substrate 100A and the display medium 200 for planarizing the driving substrate 100A.

[0047] For details, please also refer to Figure 1A and Figure 1B , the driving substrate 100A of the display device 10 of this embodiment includes a substrate 110, at least one active ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com