Preparation method of debitterized high-temperature soybean meal peptide powder capable of promoting calcium absorption

A technology of calcium absorption and soybean meal, which is applied in the field of preparation of high-temperature soybean meal peptide powder for debittering and promoting calcium absorption, which can solve the problems of less functionality, poor flavor, and single source of raw materials for peptide powder, and achieve the effect of low bitterness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

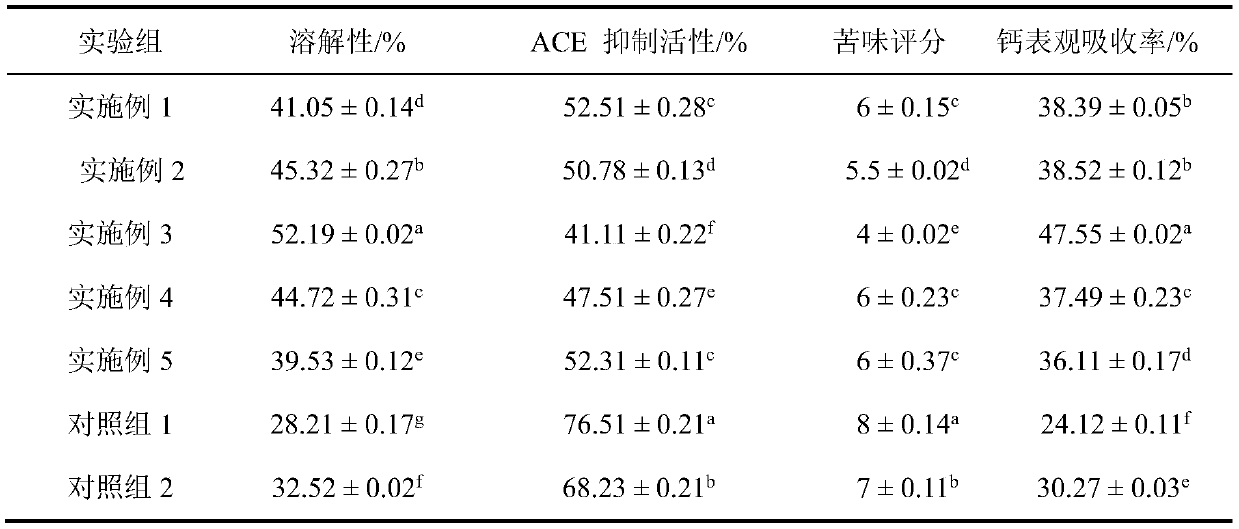

Examples

preparation example Construction

[0015] A preparation method for debittering and promoting calcium absorption of high-temperature soybean meal peptide powder, which is characterized in that the method includes the following steps: (1) high-temperature soybean meal pretreatment: crush the high-temperature soybean meal, pass through a 60-mesh sieve, and mix the soybean meal powder and water at a ratio of 1:6 Mix the ratio, stir evenly, and adjust the pH to 8.5 to obtain a high-temperature soybean meal mixture; (2) Jet cavitation treatment: The high-temperature soybean meal mixture is subjected to jet cavitation treatment to obtain a soybean meal solution, and the jet cavitation time is 3-6min; (3) Enzyme Solution: Take soybean meal solution adjusted to pH 8.5 as substrate, add compound enzyme preparation with 3%-5% of substrate mass, mix well, hydrolyze at 50°C for 3 hours, boil to kill enzyme for 20min, cool to room temperature, Obtain high-temperature soybean meal hydrolyzate; solution, described compound enzy...

Embodiment 1

[0021] A preparation method for debittering and promoting calcium absorption of high-temperature soybean meal peptide powder, which is characterized in that the method includes the following steps: (1) high-temperature soybean meal pretreatment: crush the high-temperature soybean meal, pass through a 60-mesh sieve, and mix the soybean meal powder and water at a ratio of 1:6 Mix the mixture in the same ratio, stir evenly, and adjust the pH to 8.5 to obtain a high-temperature soybean meal mixture; (2) jet cavitation treatment: perform jet cavitation treatment on the high-temperature soybean meal mixture to obtain a soybean meal solution, and the jet cavitation time is 3 minutes; (3) enzymatic hydrolysis: Take the soybean meal solution adjusted to pH 8.5 as the substrate, add a compound enzyme preparation of 3% of the substrate mass, mix well, hydrolyze at 50°C for 3 hours, boil to kill the enzyme for 20 minutes, and cool to room temperature to obtain a high-temperature soybean mea...

Embodiment 2

[0023] A preparation method for debittering and promoting calcium absorption of high-temperature soybean meal peptide powder, which is characterized in that the method includes the following steps: (1) high-temperature soybean meal pretreatment: crush the high-temperature soybean meal, pass through a 60-mesh sieve, and mix the soybean meal powder and water at a ratio of 1:6 Mix in the same ratio, stir evenly, and adjust the pH to 8.5 to obtain a high-temperature soybean meal mixture; (2) Jet cavitation treatment: The high-temperature soybean meal mixture is subjected to jet cavitation treatment to obtain a soybean meal solution, and the jet cavitation time is 6 minutes; (3) Enzymolysis: Take the soybean meal solution adjusted to pH 8.5 as the substrate, add a compound enzyme preparation of 5% of the substrate mass, mix well, hydrolyze for 3 hours at 50°C, boil to kill the enzyme for 20 minutes, and cool to room temperature to obtain a high-temperature soybean meal hydrolyzate S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vitality | aaaaa | aaaaa |

| Enzyme activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com