Mixed osthole foaming microemulsion and preparation technology

A technology of osthole and microemulsion, which can be used in emulsion delivery, medical preparations with non-active ingredients, sexual diseases, etc., and can solve problems such as irritation of mucous membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Determination of the solubility of osthole in various excipients

[0024] Take about 2mL of different oil phases, surfactants, and co-surfactants into a stoppered graduated test tube, add excess osthole raw material, vortex to disperse, shake in a constant temperature shaking box at 37°C for 48h, and centrifuge at 10,000r / min After 10 minutes, take the supernatant and dilute it with an appropriate amount of absolute ethanol, then measure the solubility of osthole in various auxiliary materials, and the results are shown in Table 1.

[0025] The solubility of table 1 osthole in excipients

[0026]

[0027] As shown in Table 1, osthole has high solubility in ethyl oleate, PGPR, OP, ODO, Labrasol, EL-40, PEG-200, and Transcutol HP, so these excipients are selected for further screening.

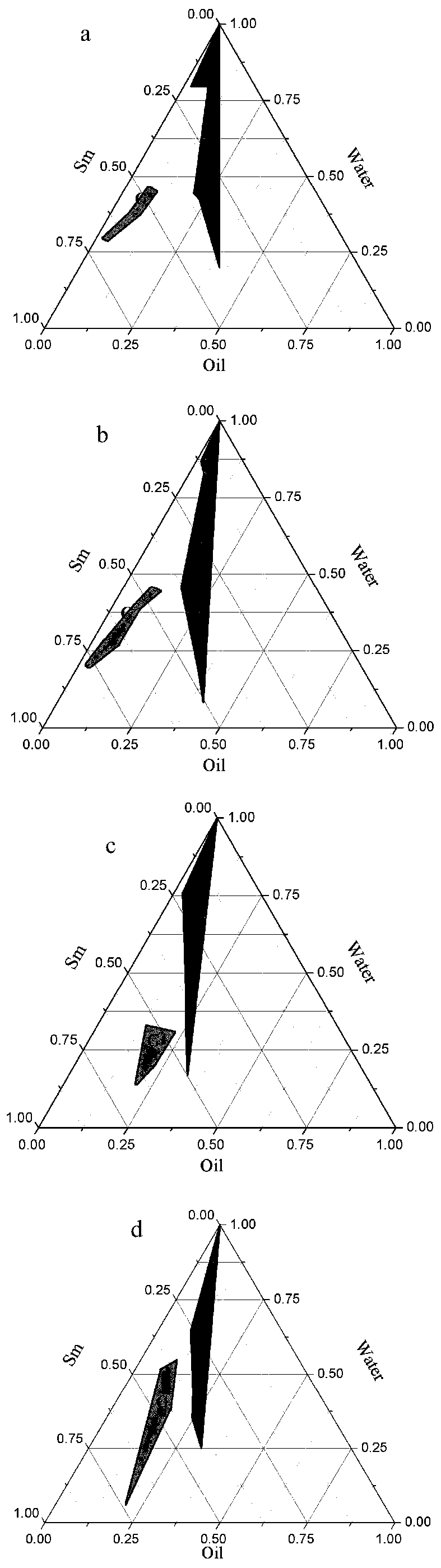

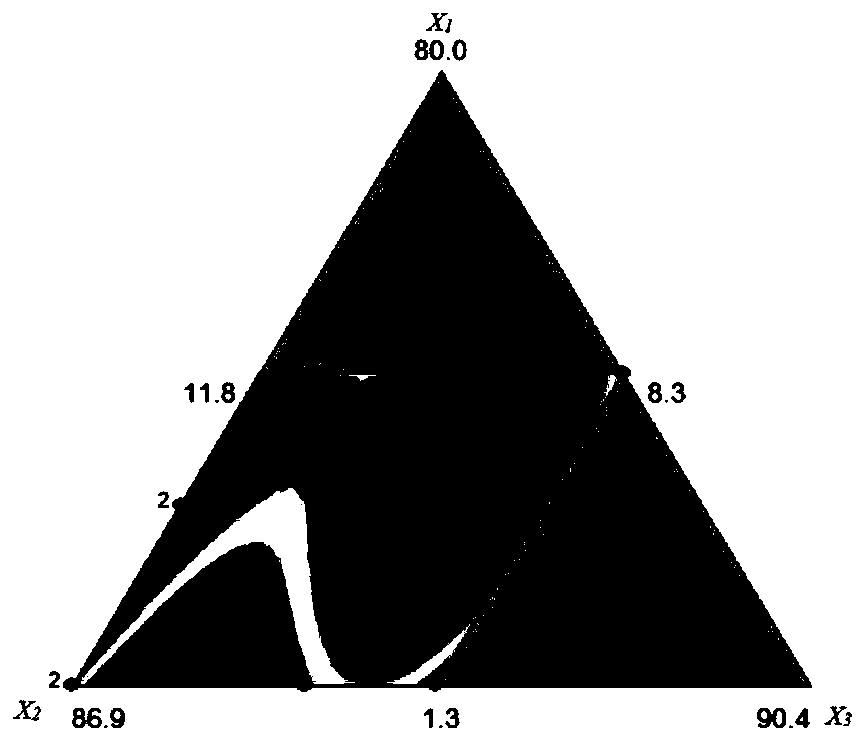

[0028] 2. Drawing of ternary phase diagram

[0029] Select the mass ratio (Km value) of surfactant and co-surfactant to be 1:1, 2:1, 3:1, 4:1 respectively, and the mass ratio of o...

Embodiment 2

[0049] Validation of the optimized prescription According to the optimal prescription, the foaming microemulsion was prepared and repeated 3 times. The ratio of the excipients and the test results are shown in Table 4. The results verify that the actual values of each index of the prescription are close to the predicted values, indicating that the D-optimal mixture design has accurate predictability for the ratio of microemulsions.

[0050] Table 4 Comparison of measured value and predicted value of optimized and verified prescription

[0051]

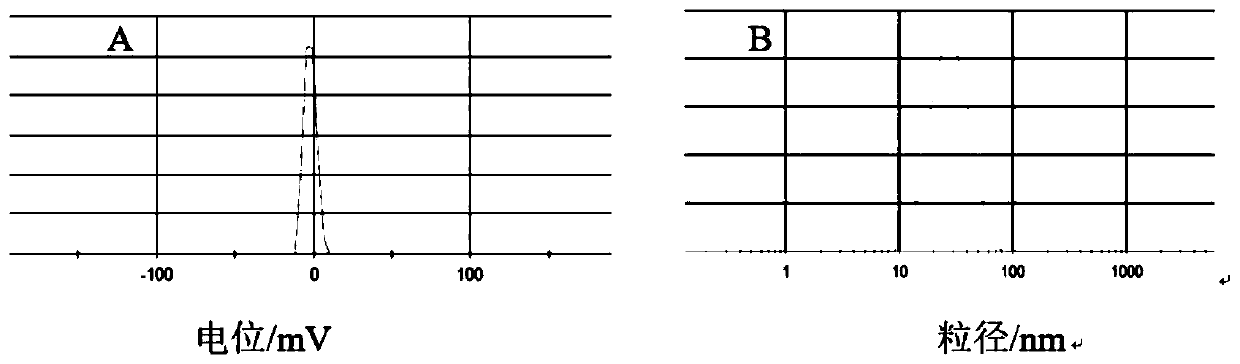

[0052] 1. Characterization of physical and chemical properties of foaming microemulsion

[0053] The microemulsion prepared according to Table 4 was used to characterize its physical and chemical properties such as potential, particle size, polydispersity coefficient, solubility and drug loading.

[0054] Appearance: The Cnidium Fructus Foaming Microemulsion is a clear and transparent liquid with light blue opalescence. Particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com