Method for catalytically synthesizing biodiesel by using solid base KF/MgO-CeO2 in spherical structure

A spherical structure, solid base technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of high reaction temperature, insufficient catalyst stability, unsatisfactory effect, etc., to achieve preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

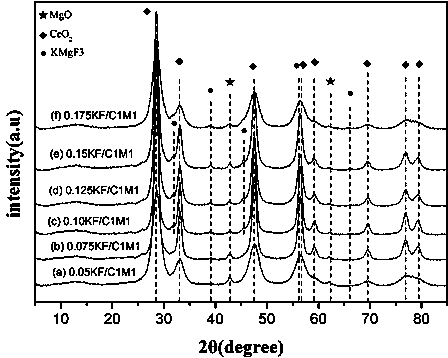

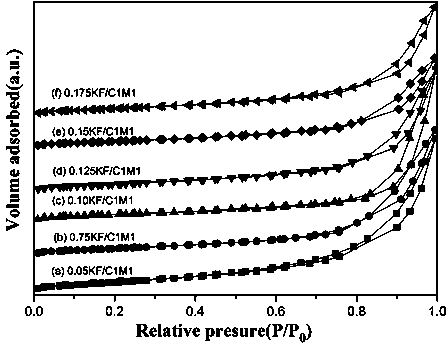

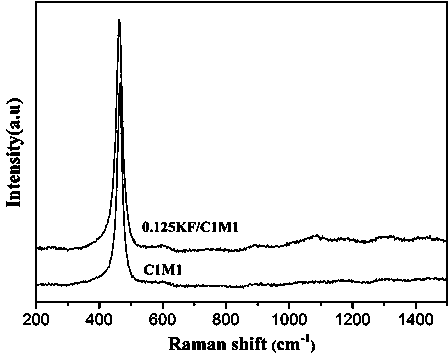

[0024] 1. Spherical structure solid base KF / MgO-CeO 2 preparation of

[0025] Mg(NO 3 ) 2 ·6H 2 O, Ce(NO 3 ) 3 ·6H 2 O is added into deionized water according to a 1:1 molar ratio to form solution A with a metal ion molar solubility of 0.2 mol / L; configure 1 mol / L of sodium hydroxide solution B, and slowly add solution B to solution A until Mix solution pH=10, heat and stir at 40°C for 5 hours to obtain a sol-gel mixture, stand still for 1 hour, wash with a mixture of alcohol and water with a mass ratio of 0.5 to 1:1 and suction filter until the pH of the washing solution is 7, and the obtained filter cake is released Dry in an oven at 100°C overnight, then grind to a fine powder, put it into a muffle furnace and calcinate at 550°C for 4 hours at a heating rate of 2°C / min to obtain spherical structure MgO-CeO 2 Carrier, carrier particle diameter 15~28nm, specific surface area 59~94m 2 / g.

[0026] Then KF, the prepared spherical structure MgO-CeO 2Carrier and impregn...

Embodiment 2

[0029] Embodiment 2 operating steps are the same as embodiment 1, but the solid base catalyst is 0.1KF / CeO 2 , namely KF and CeO 2 The mass ratio of carrier is 0.1, and the mass yield of biodiesel product is 25.4%.

Embodiment 3

[0030] Embodiment 3 operating steps are the same as embodiment 1, but the solid base catalyst is 0.1KF / MgO-CeO 2 , where KF and MgO-CeO 2 The mass ratio of the carrier is 0.1, the molar ratio of Mg and Ce is 1:3, and the mass yield of biodiesel product is 85.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com