Grouting material for concrete reinforcement

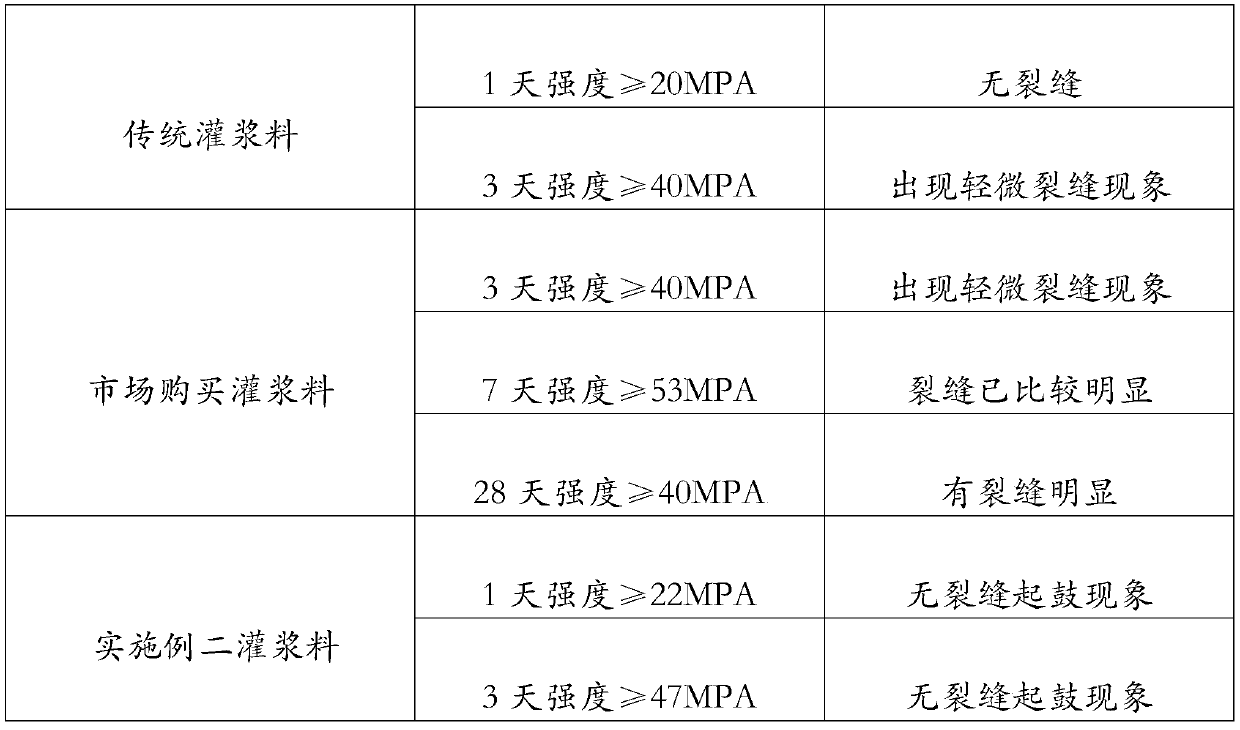

A technology of concrete reinforcement and grouting materials, which is applied in the field of building structure reinforcement, can solve problems such as cracking and swelling of grouting materials, and achieve the effects of improving cohesiveness, tensile strength, and stable strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A concrete reinforcement grouting material, comprising the following raw materials in parts by weight: ordinary portland cement 600kg, sulphoaluminate cement 80kg, quartz sand 1000kg, expansion agent 0.3kg, water reducing agent 3kg, defoamer 1kg, cellulose Ether 1kg, redispersible latex powder 4kg, polypropylene short fiber 0.8kg, silicon micropowder 40kg.

[0030] The preparation method of the concrete reinforcement grouting material is as follows: mixing and stirring each raw material evenly.

[0031] The application of the concrete reinforcement grouting material in self-leveling ground repair: the concrete reinforcement grouting material is mixed with water and stirred evenly, and the reinforcement grouting material is obtained for use; the surface of the concrete that needs to be repaired and reinforced is chiseled, and the broken sand and dust are cleaned , and then sprinkle water on its surface. After the surface is dry, apply a layer of styrene-acrylic emulsion ...

Embodiment 2

[0033] A concrete reinforcement grouting material, comprising the following raw materials in parts by weight: 800kg of ordinary portland cement, 100kg of sulphoaluminate cement, 1100kg of quartz sand, 0.5kg of CSA expansion agent, 3.5kg of polycarboxylate water reducer, P803 Foaming agent 1.5kg, cellulose ether 1.3kg, redispersible latex powder 5kg, polypropylene short fiber 1.1kg, silicon micropowder 50kg.

[0034] The preparation method of the concrete reinforcement grouting material is as follows: mixing and stirring each raw material evenly.

[0035] Application of the concrete reinforcement grouting material in self-leveling ground repair: mix and stir the concrete reinforcement grouting material with a weight ratio of 100:16 and water evenly to obtain a reinforcement grouting material for use; chiseling the surface of the concrete that needs to be repaired and reinforced Treatment, clean up the crushed sand and dust, and then sprinkle water on the surface. After the surf...

Embodiment 3

[0037] A concrete reinforcement grouting material, comprising the following raw materials in parts by weight: 800kg of ordinary Portland cement, 110kg of sulphoaluminate cement, 1150kg of quartz sand, 0.4kg of CSA expansion agent, 3kg of polycarboxylate water reducer, and P803 defoaming agent Agent 1.6kg, cellulose ether 1.2kg, redispersible latex powder 5.3kg, polypropylene short fiber 1.1kg, silicon micropowder 55kg.

[0038] The preparation method of the concrete reinforcement grouting material is as follows: mixing and stirring each raw material evenly.

[0039] Application of the concrete reinforcement grouting material in self-leveling ground repair: mix and stir the concrete reinforcement grouting material with a weight ratio of 100:18 and water evenly to obtain a reinforcement grouting material for use; chiseling the surface of the concrete that needs to be repaired and reinforced Treatment, clean up the crushed sand and dust, and then sprinkle water on the surface. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com