Liquid crystal medium, polarization separation film, and preparation method thereof

A polarization separation film and liquid crystal medium technology, applied in liquid crystal materials, polarizing elements, chemical instruments and methods, etc., can solve problems such as poor polarization separation effect, difficult orientation of liquid crystal polymers, and uneven optical properties of birefringent films. Good temperature adaptability, good optical anisotropy, and good polarization separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

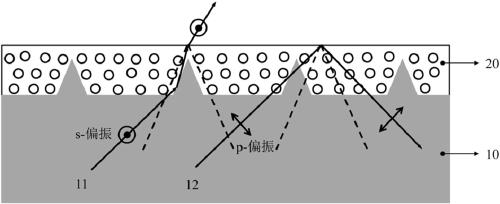

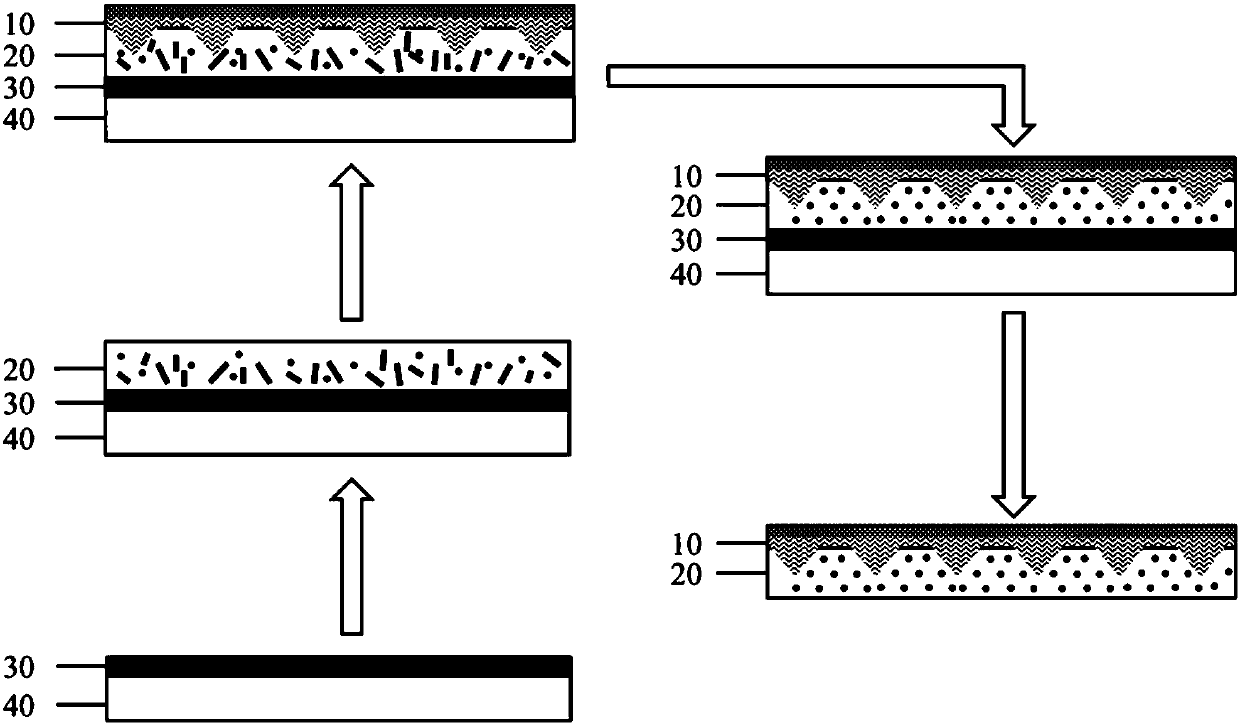

[0046] Such as figure 2 As shown, the preparation method of the polarization separation film includes the following steps: first, an alignment layer 30 is formed on the substrate 40, and the formation methods include rubbing alignment, photo-controlled alignment technology, oblique evaporation method, LB film technology, etc. The substrate 40 may include hard materials (such as optical glass), or flexible substrates (such as PET) and the like. The material of the alignment layer 30 may be polyimide. Next, a liquid crystal medium in a liquid crystal state is coated on the alignment layer 30 to form a birefringent layer 20 in a liquid crystal state. Then, the base layer 10 and the birefringent layer 20 in the liquid crystal state are laminated by means of a device having a laminating function. When laminating, the base layer 10 can be positioned above the birefringent layer 20, and the upper surface of the base layer 10 can be gradually pressurized, so that the surface of the...

Embodiment 1

[0050]

[0051] Among them, the Δn of the liquid crystal medium is 0.191, where n o It is 1.51, which is the n of common light guide plate materials (such as PMMA) p match. The clearing point temperature of the liquid crystal medium is 131°C, and its working temperature range as a birefringent layer medium is greater than the glass transition temperature of PET (70°C) and the glass transition temperature of PEN (120°C). The polarization contrast ratio of the polarization separation film is 6.5:1.

Embodiment 2

[0053]

[0054]

[0055] Among them, the Δn of the liquid crystal medium is 0.191. The polarization contrast ratio of the polarization separation film is 6:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| optical anisotropy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com