Active and passive collaborative heat storage wall heating system for solar greenhouse

A solar greenhouse and heating system technology, applied in greenhouse cultivation, heating devices, solar heating devices, etc., can solve the problems of limited heat storage of walls, reduction of active heat storage energy efficiency, crop chilling damage and freezing damage, etc. The effect of high heating efficiency, improving heat collection intensity and efficiency, and preventing environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

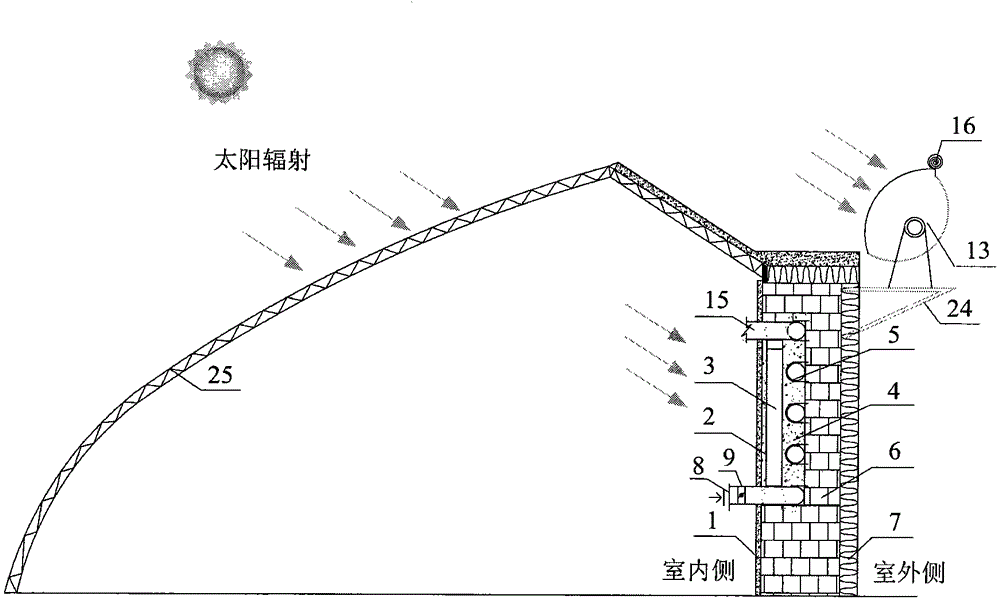

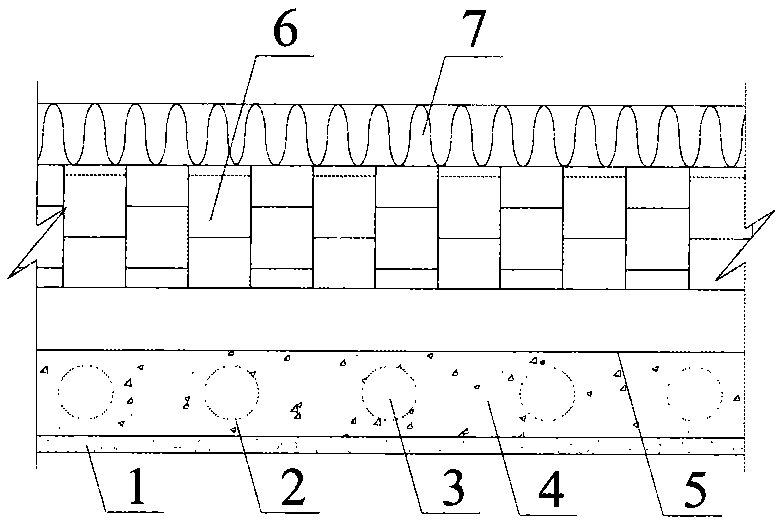

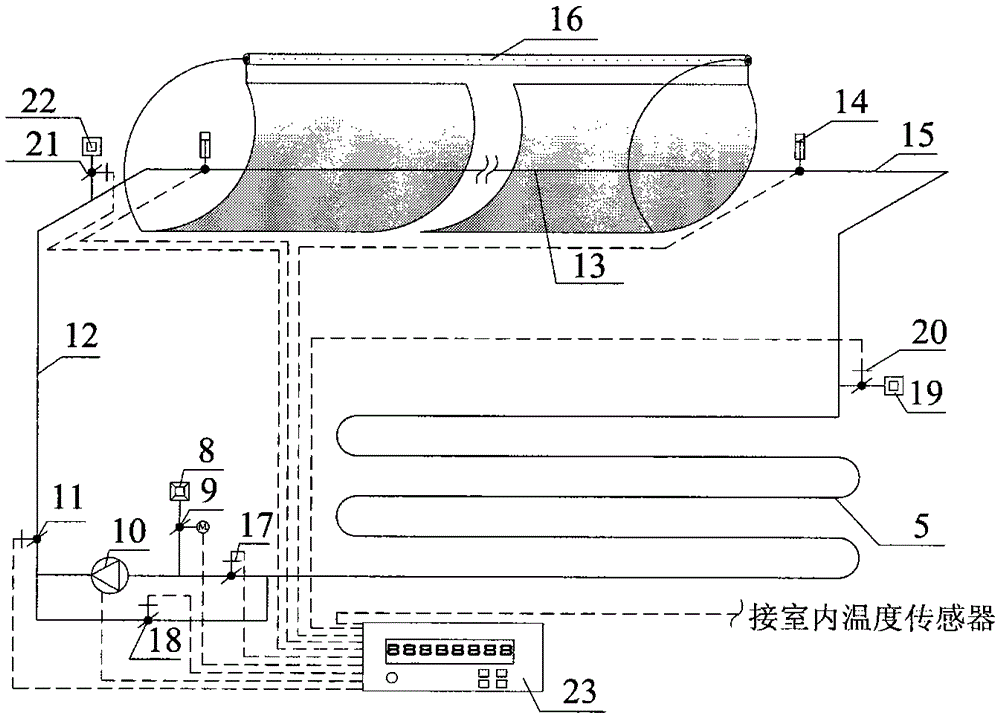

[0036] Attached below Figure 1-3 Specific embodiments of the present invention will be described in detail.

[0037] Such as Figure 1-3 As shown, the active and passive collaborative thermal storage wall heating system of the solar greenhouse consists of a phase change thermal storage wall, a concentrating solar air heat collector system, an active thermal storage heating system and an equipment control unit. The phase-change thermal storage wall is composed of a cement mortar layer 1, a phase-change material 3 encapsulated by a steel column barrel 2, a thermal storage coil 5 and sandstone cement 4 from the indoor side to the outdoor side. The load-bearing block layer 6 and the insulation layer 7 are composed; the solar air heat collector system is composed of multiple concentrating solar air heat collectors 13 connected in series, and a summer sunshade device 16 is arranged on the upper part of the heat collector; the active storage The heat supply system is composed of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com