An edge computing controller and its working method for intelligent manufacturing

An edge computing and intelligent manufacturing technology, applied in the direction of computer control, general control system, control/regulation system, etc., can solve the problems of limited development interface, fixed controller function, difficulty in meeting the demand of edge computing data flow, etc., to achieve Improve the applicability, improve the interface ability and computing ability, and facilitate the effect of popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the purpose, technical solution and advantages of the present invention clearer and clearer, the present invention will be further described in detail with reference to the accompanying drawings and examples.

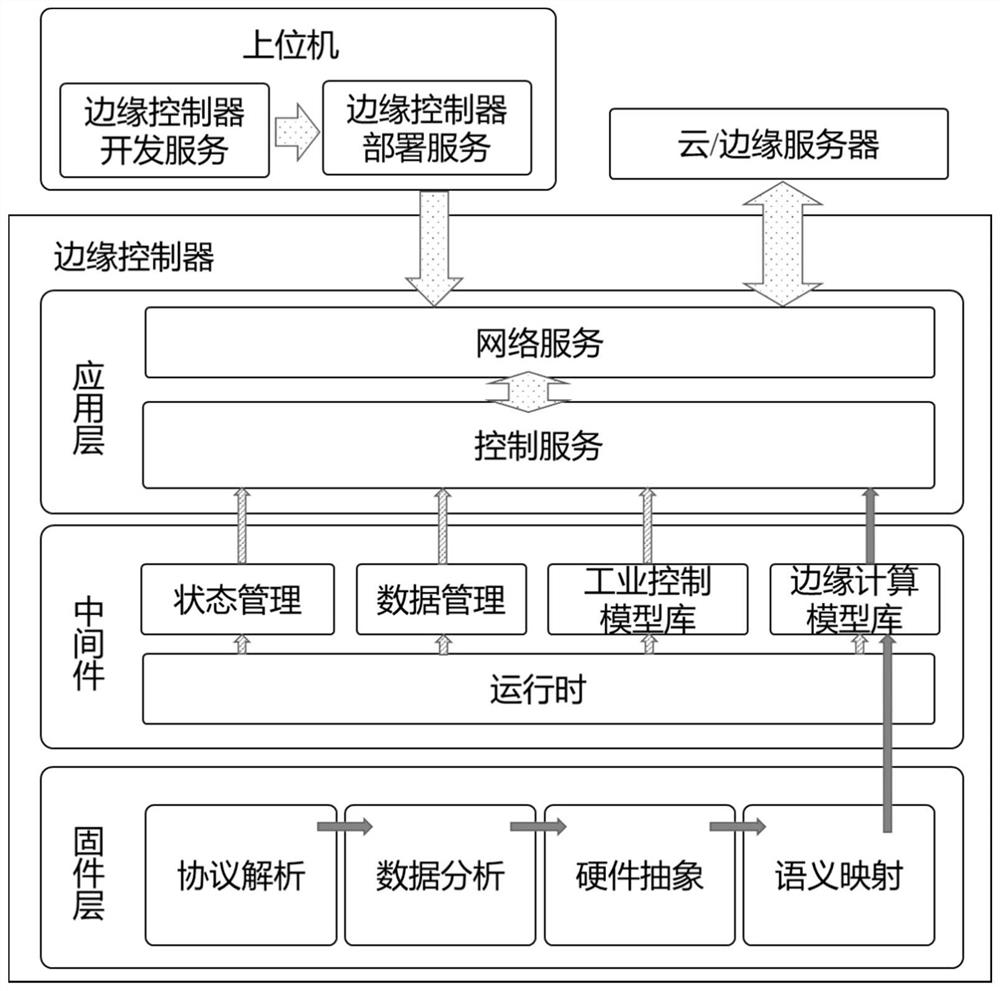

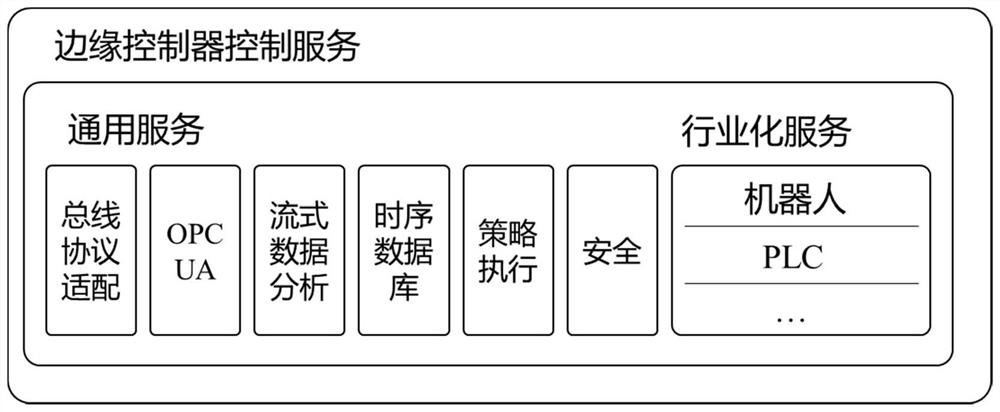

[0046] see figure 1 , including two parts: the edge computing controller and the upper computer for intelligent manufacturing. The edge controller mainly involves: firmware layer, middleware and application layer.

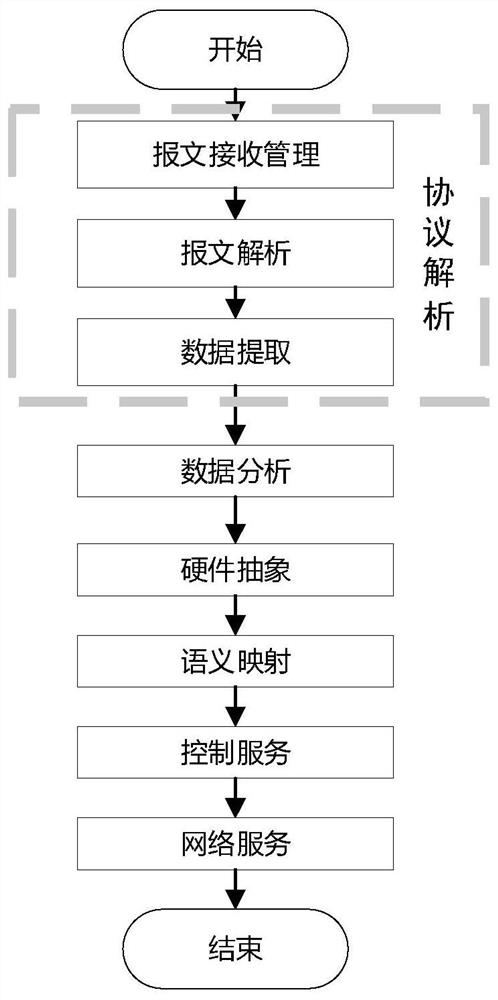

[0047] The firmware layer provides the bottom device driver for the edge controller, including IO interface, industrial bus interface, etc., and summarizes and classifies the collected data information. It includes four parts: protocol analysis, data analysis, hardware abstraction, and semantic mapping.

[0048] Among them, the protocol analysis means that the edge controller should have protocol analysis functions such as field bus or real-time Ethernet, and the edge controller of the production equipment can communicate with the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com