Sports instrument wire harness

A sports equipment and wiring harness technology, applied in the field of sports equipment wiring harness, can solve the problems of poor tensile fracture resistance and twisting fracture resistance, poor wire harness strength, short service life, etc., to improve toughness, compression resistance, and thermal conductivity Good, the effect of improving strength and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

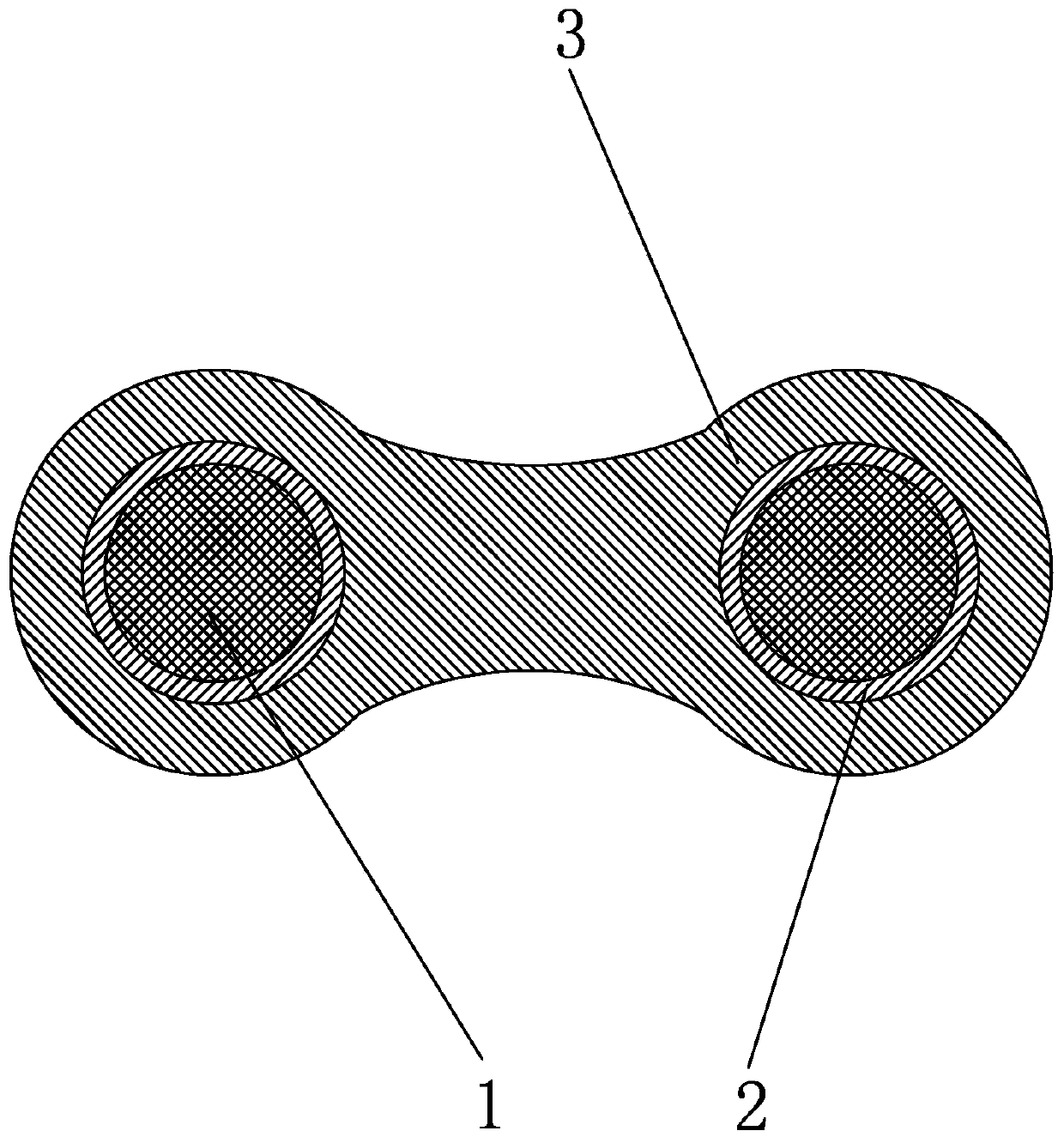

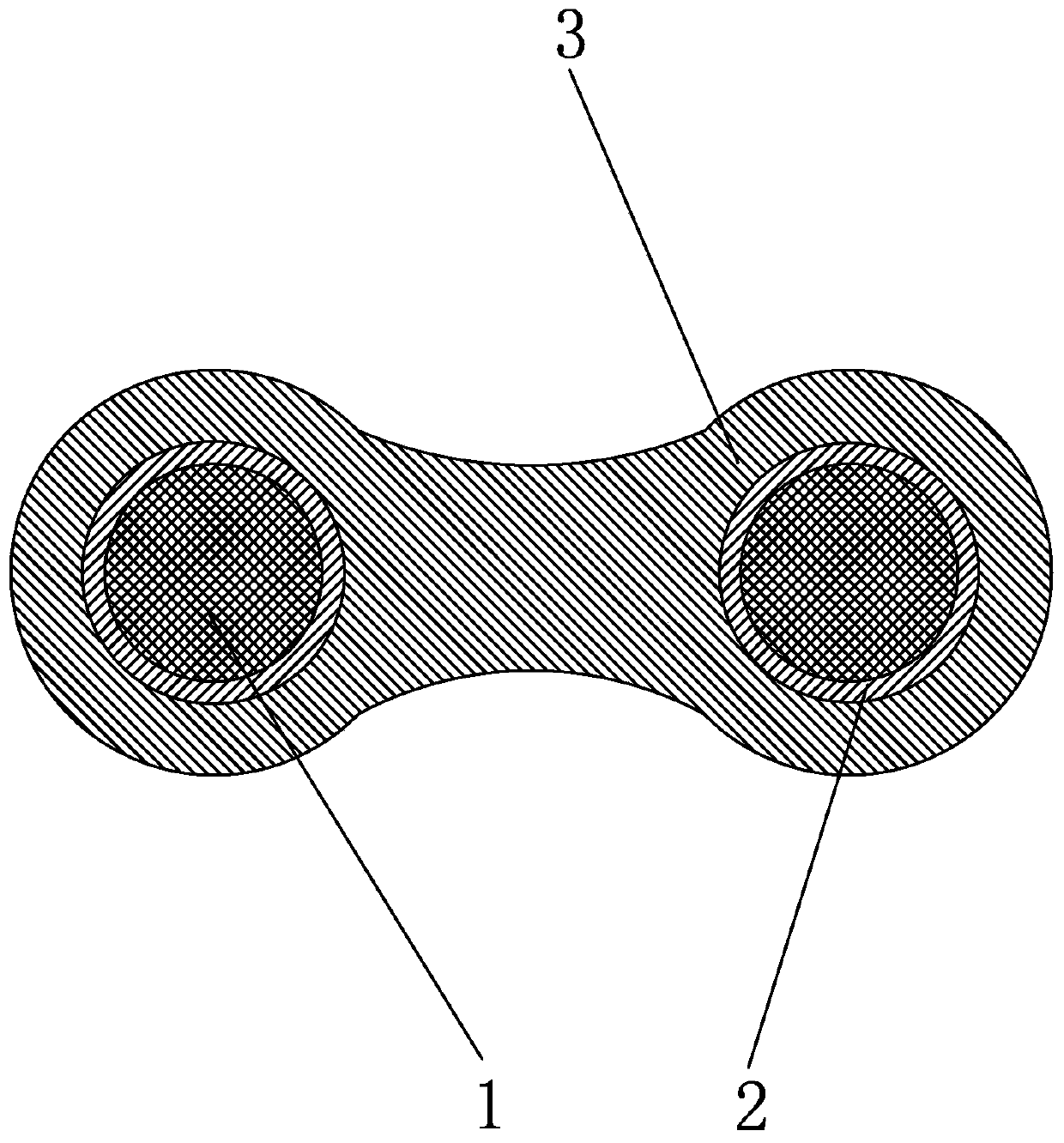

[0017] combine figure 1 , The invention discloses a wire harness for sports equipment, which includes a wire harness body. The wire harness body has a flat structure, which can effectively prevent the wire harness from twisting and knotting, and is easy to organize. The wire harness body includes a core wire 1 , an aramid wrapping layer 2 and an insulating outer layer 3 . The core wire 1 is made of aluminum alloy conductive wire and carbon fiber conductive wire twisted in parallel. The core wire 1 is mainly made of aluminum, instead of the traditional copper core wire 1, the flexibility and weight of the core wire 1 are improved, and the bending performance of the core wire 1 is greatly improved. On the one hand, the carbon fiber conductive thread can play a role of structural reinforcement and improve the strength of the core wire 1 , and on the other hand, can improve the thermal conductivity of the core wire 1 . The diameter of the aluminum alloy conductive wire is 0.25-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com