Natto mushroom sauce and preparation method thereof

A technology of mushroom sauce and natto, which is applied in the direction of food science and the like, can solve the problem of late start of the natto industry, and achieve the effects of simple and easy preparation method, rich sauce flavor and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

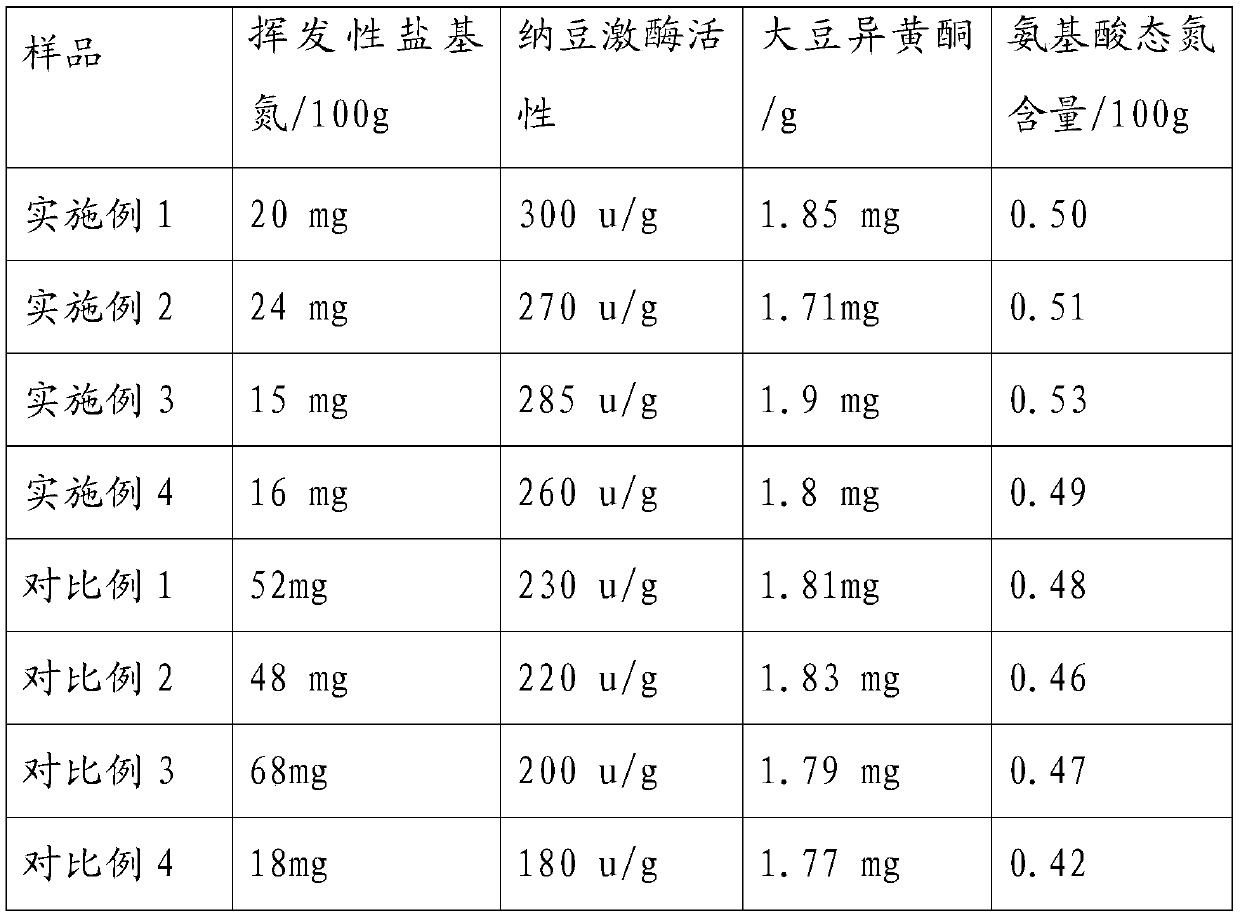

Examples

Embodiment 1

[0024] A natto and shiitake mushroom sauce, comprising the following raw materials in parts by weight:

[0025] 145 parts of natto, 55 parts of shiitake mushroom handle, 135 parts of rapeseed oil, 12 parts of red oil watercress, 43 parts of soybean paste, 22 parts of sweet noodle sauce, 28 parts of fermented bean curd, 23 parts of light soy sauce, 8 parts of shiitake mushroom powder, 8 parts of monosodium glutamate, 10 parts of chicken essence, 1.8 parts of white sugar and 0.25 parts of potassium sorbate.

[0026] A preparation method of natto mushroom sauce, comprising the following steps:

[0027] S1. Pretreatment: wash the mushroom stalks of the formula amount, add to boiling water with 4 times the weight of the mushroom stalks and soak for 1.8h, then cut into 0.4cm×0.4cm particles;

[0028] S2. Frying: Add the amount of rapeseed oil in the pot, heat it until it smokes, pour the pretreated mushroom stalks, and fry for 6 minutes; then add red oil and watercress in the pot, ...

Embodiment 2

[0038] A kind of natto mushroom sauce, comprising the following raw materials in parts by weight: 140 parts of natto, 50 parts of mushroom stems, 130 parts of rapeseed oil, 10 parts of red oil watercress, 40 parts of soybean paste, 20 parts of sweet noodle sauce, 25 parts of fermented bean curd, raw 20 parts of soy sauce, 6 parts of mushroom powder, 6 parts of monosodium glutamate, 8 parts of chicken essence, 1.5 parts of white sugar and 0.2 parts of potassium sorbate.

[0039] A preparation method of natto mushroom sauce, comprising the following steps:

[0040] S1. Pretreatment: Wash the mushroom stalks of the formula amount, add to boiling water with 3 times the weight of the mushroom stalks and soak for 1.5h, then cut into 0.4cm×0.4cm particles;

[0041] S2. Frying: Add the amount of rapeseed oil in the pot, heat it until it smokes, pour the pretreated mushroom stalks, and fry for 5 minutes; then add red oil and watercress in the pot, and fry for 4 minutes on low heat , a...

Embodiment 3

[0051] A kind of natto mushroom sauce, comprising the following raw materials in parts by weight: 150 parts of natto, 60 parts of mushroom stems, 140 parts of rapeseed oil, 15 parts of red oil watercress, 50 parts of soybean paste, 25 parts of sweet noodle sauce, 30 parts of fermented bean curd, raw 25 parts of soy sauce, 9 parts of mushroom powder, 9 parts of monosodium glutamate, 12 parts of chicken essence, 2 parts of white sugar and 0.3 parts of potassium sorbate.

[0052] A preparation method of natto mushroom sauce, comprising the following steps:

[0053] S1. Pretreatment: wash the mushroom stalks of the formula amount, add to boiling water with 3.5 times the weight of the mushroom stalks and soak for 2 hours, then cut into 0.4cm×0.4cm particles;

[0054] S2. Frying: Add the amount of rapeseed oil in the pot, heat it until it smokes, pour the pretreated mushroom stalks, and fry for 8 minutes; then add red oil and watercress in the pot, and fry for 5 minutes on low heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com