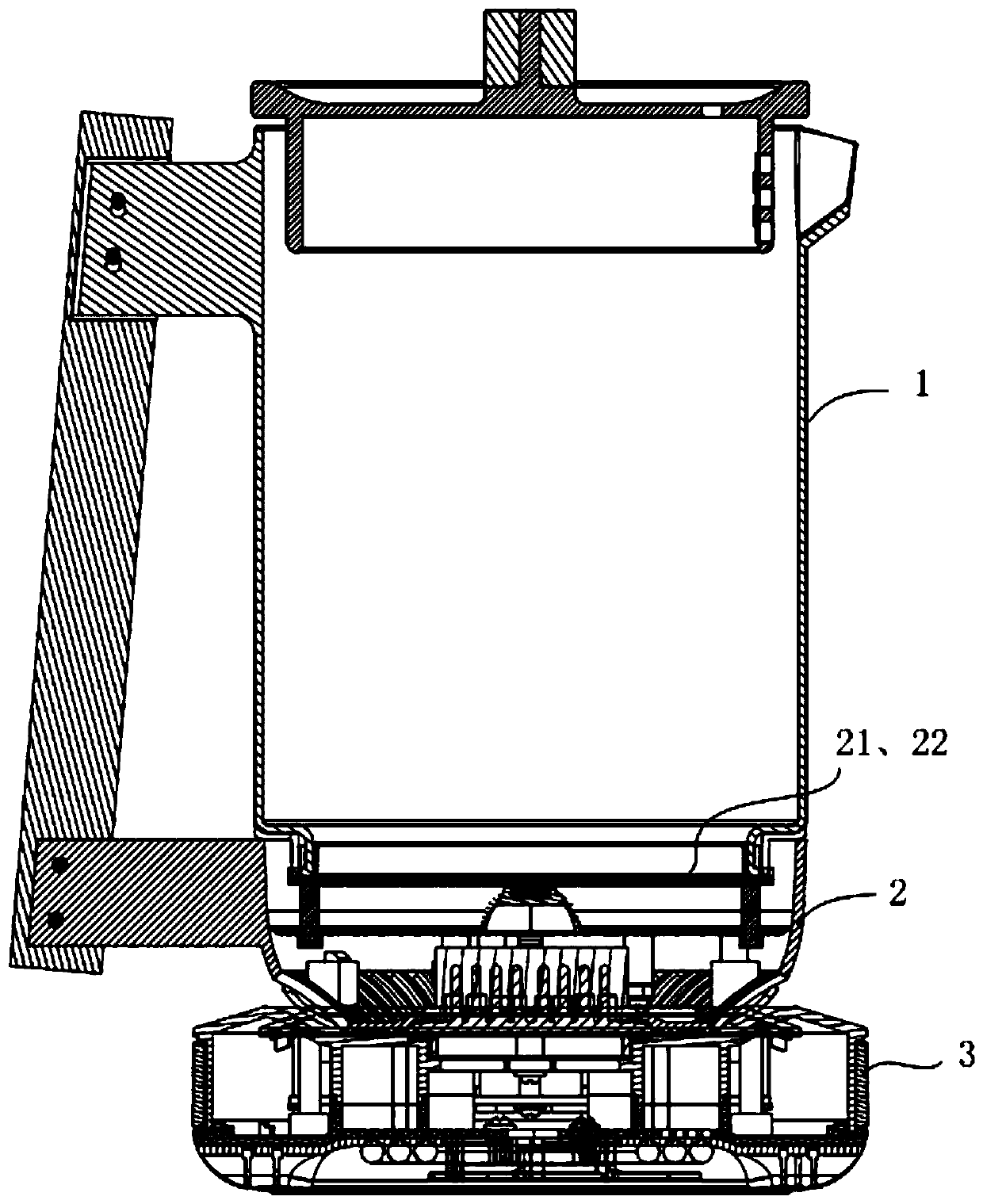

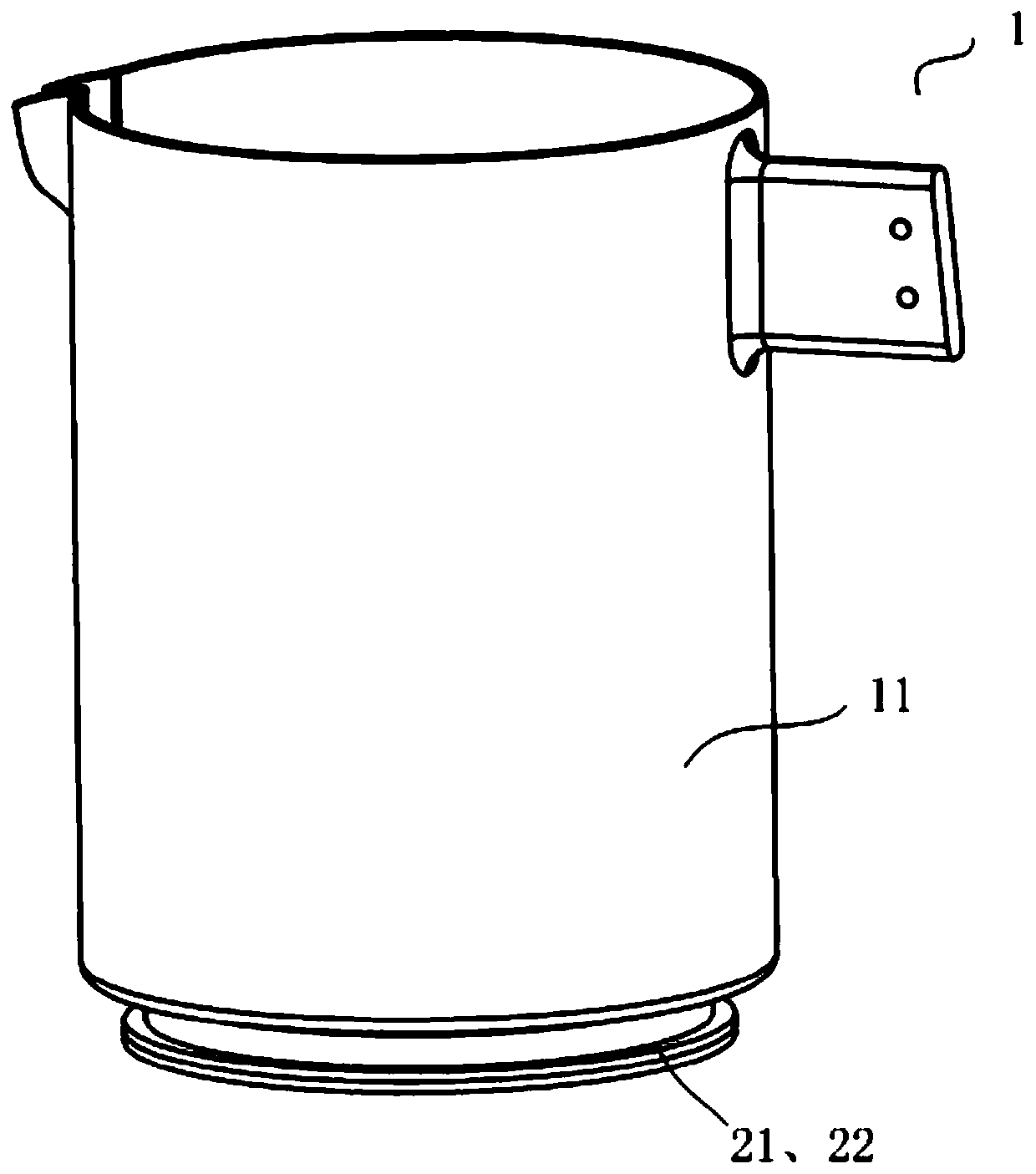

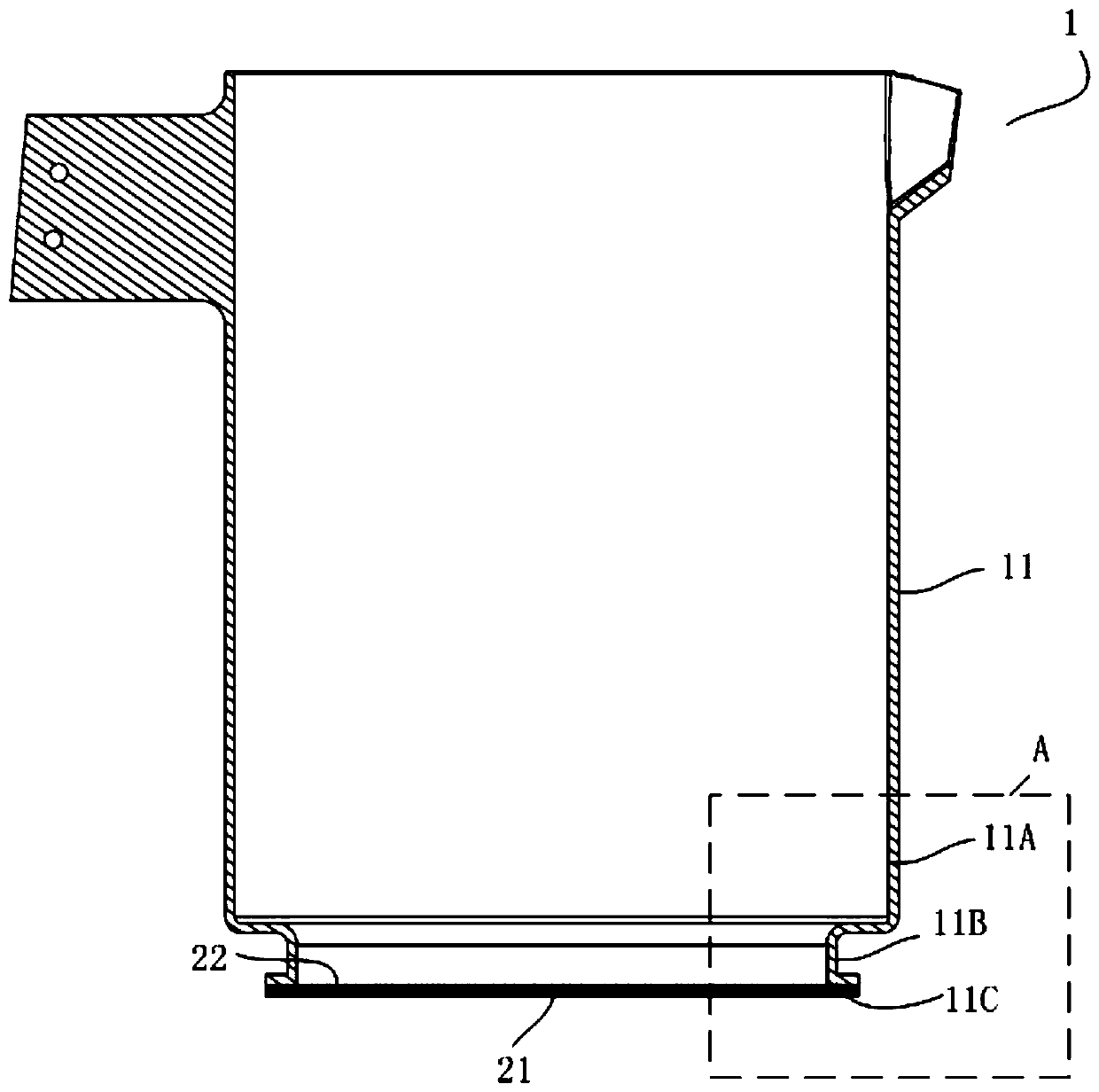

Non-metallic heating device for cooking

A heating device, non-metal technology, applied in the direction of boiling water appliances, etc., can solve the problems of low cost, achieve the effects of light weight, good mechanical strength, and ensure the safety of electricity consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] 1. Preparation of front glass glaze (in contact with water): mix 72% SiO 2 , 3%Al 2 o 3 , 14% B 2 o 3 , 5%Na 2 O, 5.5% CaO, 0.5% SiC, mixed evenly, kept at 1650°C for 1 hour, then water quenched to obtain transparent glass slag, dried, crushed, and passed through a 250-mesh sieve to obtain a powder with an average particle size of 1.5-2.5 μm body.

[0099] 2. Preparation of front glass glaze coating: mix the front glass glaze powder and organic carrier evenly according to the ratio of 73:27, and pass through a three-roll mill to obtain a viscous fluid with a viscosity of 30-70 Pa.S and a fineness of less than 12 μm .

[0100] 3. Preparation of back glass powder (printed circuit): 77% SiO 2 , 3%Al 2 o 3 , 14% B 2 o 3 , 5%Na 2 O, 0.5% CaO, mixed evenly, kept at 1650°C for 1 hour, then quenched in water to obtain transparent glass slag, dried, crushed, and passed through a 250-mesh sieve to obtain a powder with an average particle size of 1.5-2.5 μm.

[0101] ...

Embodiment 2

[0105] 1. Preparation of front glass glaze (in contact with water): mix 62% SiO 2 , 17%Al 2 o 3 , 10% B 2 o 3 , 7.7% CaO, 1.3% MgO, 0.5% Y 2 o 3 , 1.5% SiC, mixed evenly, kept at 1650°C for 1 hour, and then quenched in water to obtain transparent glass slag, dried, crushed, and passed through a 250-mesh sieve to obtain a powder with an average particle size of 1.5-2.5 μm.

[0106] 2. Preparation of front glass glaze coating: mix the front glass glaze powder and organic carrier evenly at a ratio of 75:25, and pass through a three-roll mill to obtain a viscous fluid with a viscosity of 30-70 Pa.S and a fineness of less than 12 μm .

[0107] 3. Preparation of back glass powder (printed circuit): 62% SiO 2 , 17%Al 2 o 3 , 10% B 2 o 3 , 7.7% CaO, 3.3% MgO, mix evenly, keep the temperature at 1650°C for 1 hour, then quench in water to obtain transparent glass slag, after drying, crushing, and passing through a 250-mesh sieve, a powder with an average particle size of 1.5-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com