A preparation method of au-ag alloy nanoparticles with tunable plasmon resonance

An alloy nanoparticle, plasmon resonance technology, applied in nanotechnology and other directions, can solve the problems of low extinction coefficient, easy oxidation, difficulty, etc., and achieve the effect of good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Synthesis of silver nanoparticles:

[0021] a. Preparation of silver seed solution: Take a 250mL round bottom flask, add 20mL 1wt% sodium citrate aqueous solution and 75mL water, stir in an oil bath at 70°C for 15min, then add 1.7mL 1wt% AgNO 3 aqueous solution, stirred vigorously, and quickly added 0.1 wt% freshly reconstituted NaBH 4 solution, stirred vigorously at 70°C for 1 hour, cooled naturally to room temperature, added water to make it up to 100mL, and obtained a solution of silver nano-seeds;

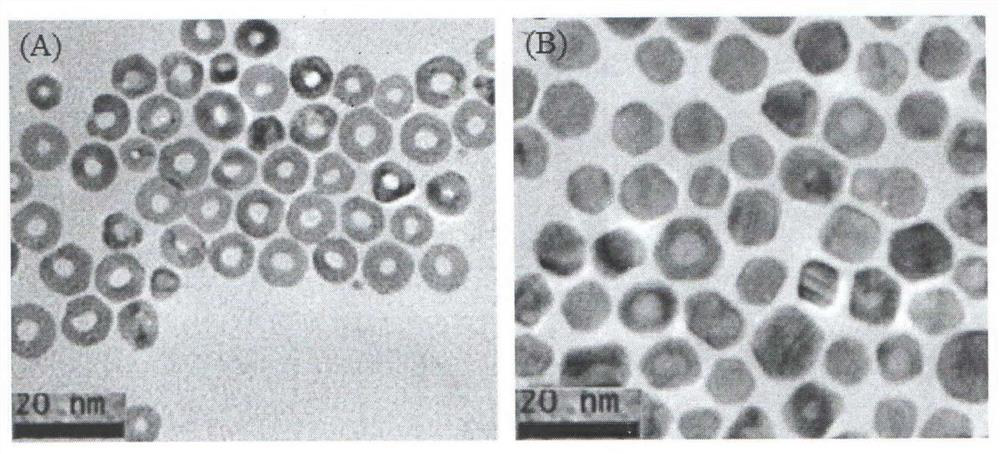

[0022] b. Growth of silver seeds: Add 1mL of sodium citrate solution to a 100mL beaker, add 75mL of water, boil for 15min, add 5mL of silver nanoseeds obtained in step a, stir vigorously, then quickly add 0.85mL of 1wt% AgNO 3 The solution was stirred for 1 h under boiling, the obtained solution was naturally cooled to room temperature, centrifuged and washed, and the centrate was dispersed in the aqueous solution to obtain 10 nm spherical silver nanoparticles;

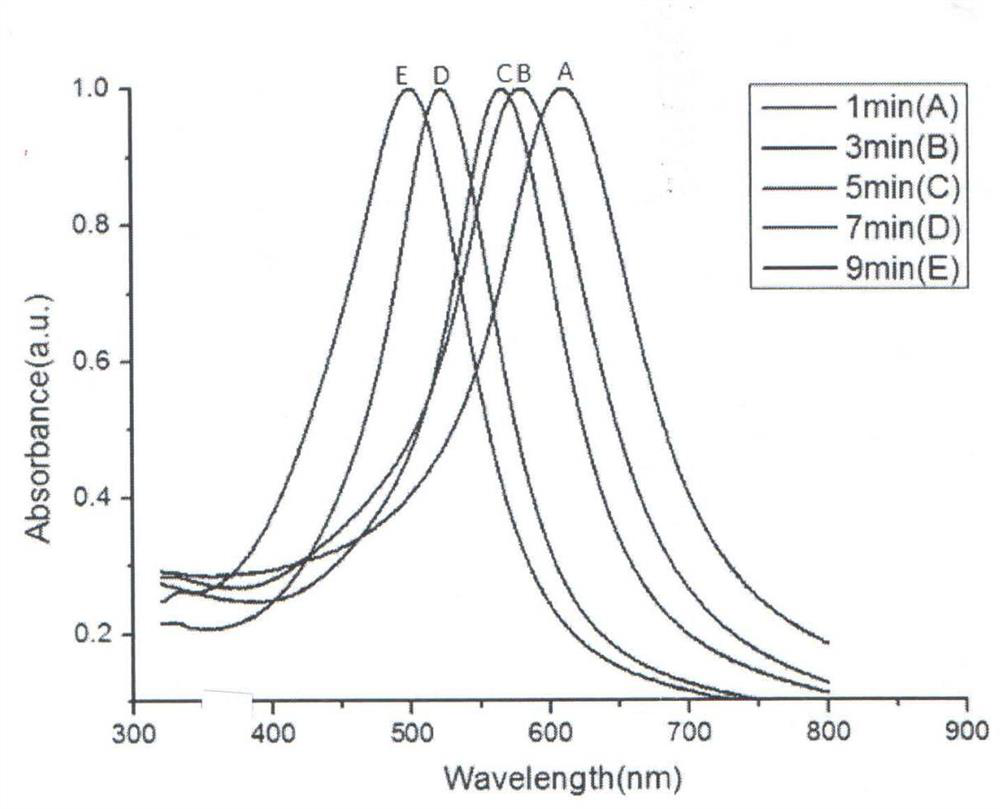

[0023...

Embodiment 2

[0026] Synthesis of silver nanoparticles:

[0027] a. Preparation of silver seed solution: Take a 250mL round bottom flask, add 20mL 1wt% sodium citrate aqueous solution and 75mL water, stir in an oil bath at 70°C for 15min, then add 1.7mL 1wt% AgNO 3 aqueous solution, stirred vigorously, and quickly added 0.1 wt% freshly reconstituted NaBH 4 solution, stirred vigorously at 70°C for 1 hour, cooled naturally to room temperature, added water to make it up to 100mL, and obtained a solution of silver nano-seeds;

[0028] b. Growth of silver seeds: Add 1mL of sodium citrate solution to a 100mL beaker, add 75mL of water, boil for 15min, add 5mL of silver nanoseeds obtained in step a, stir vigorously, then quickly add 0.85mL of 1wt% AgNO 3 solution, stirred for 1 h under boiling, and repeated 1 time to add 1 mL of sodium citrate solution to the solution, followed by rapid addition of 0.85 mL of 1wt% AgNO 3 solution, stirring for 1 h under boiling, naturally cooling the final obtain...

Embodiment 3

[0032] Synthesis of silver nanoparticles:

[0033] a. Preparation of silver seed solution: Take a 250mL round bottom flask, add 20mL 1wt% sodium citrate aqueous solution and 75mL water, stir for 15min under a temperature of 70°C in an oil bath, then add 1.7mL 1wt% AgNO3 aqueous solution, stir vigorously, and quickly Add 0.1 wt% freshly configured NaBH 4 solution, stirred vigorously at 70°C for 1 hour, cooled naturally to room temperature, added water to make it up to 100mL, and obtained a solution of silver nano-seeds;

[0034] b. Growth of silver seeds: Add 1mL of sodium citrate solution to a 100mL beaker, add 75mL of water, boil for 15min, add 5mL of silver nanoseeds obtained in step a, stir vigorously, then quickly add 0.85mL of 1wt% AgNO 3 solution, stirred for 1 h under boiling, and repeated 4 times to add 1 mL of sodium citrate solution to the solution, followed by rapid addition of 0.85 mL of 1 wt% AgNO 3 solution, stirring for 1 h under boiling, naturally cooling the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com