High-gloss scratch-resistant extrusion-grade modified polypropylene material, preparation method and automobile external water slot

A polypropylene material and scratch-resistant technology, which is used in the field of water-cutting, preparation, high-gloss and scratch-resistant extrusion-grade modified polypropylene materials, and modified polypropylene materials. It can solve the complex production process and is not suitable for automobiles. The development trend of diversification of exterior appearance, low scratch resistance and other issues, to reduce processing cost pressure, colorful appearance effect, good scratch resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

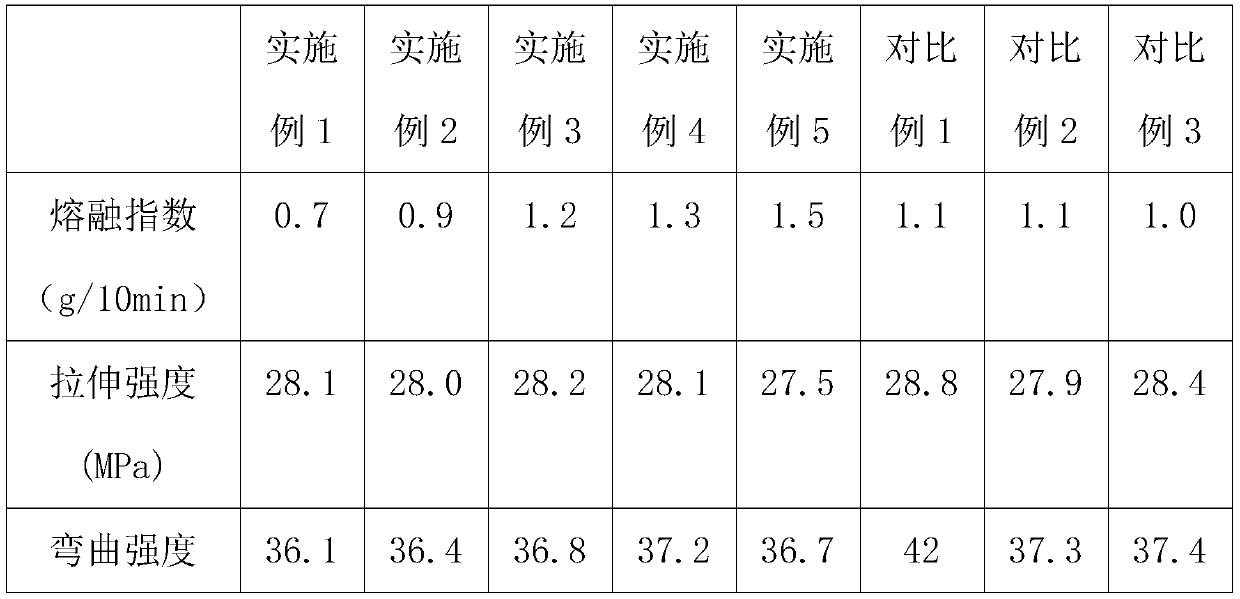

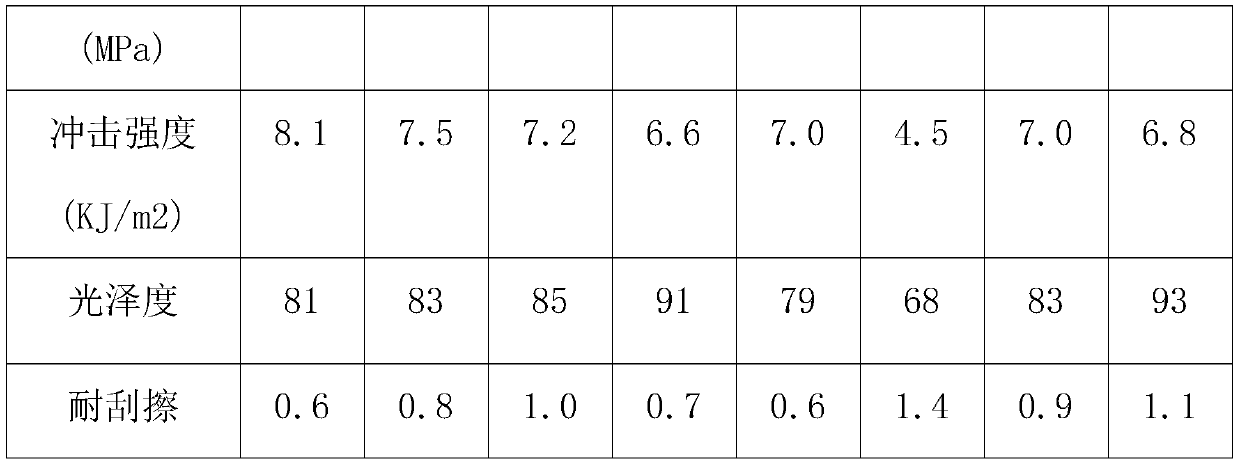

Examples

Embodiment 1

[0031] PP resin: 95 parts

[0032] Precipitated barium sulfate masterbatch: 0 parts

[0033] Toughener: 5 parts

[0034] Antioxidant: 0.7 parts

[0035] UV absorber: 0.6 parts

[0036] Nucleating agent: 0.2 parts

[0037] Anti-scratch agent: 0.5 parts

[0038] High-gloss masterbatch: 0.5 parts

[0039] In this example, the PP resin is Ningbo Formosa Plastics 5003H, and the random copolymerization method and extrusion granulation process optimization ensure its high gloss and few crystal points; the precipitated barium sulfate masterbatch is Liaoning Beihai Talc Group 3810, microscopic The spherical structure makes the appearance have a high gloss; the toughening agent is ExxonMobil propylene-based elastomer 6202; the antioxidant is BASF 1010, 168 and PS802 compound antioxidant system; the ultraviolet absorber is Cytec 3808 and 5411; the nucleating agent is Asahi Denka NA-960; the scratch resistance agent is Dow Corning MB-50-001G2; the high-gloss color masterbatch is a s...

Embodiment 2

[0041] Polypropylene resin: 85 parts

[0042] Precipitated barium sulfate masterbatch: 10 parts

[0043] Toughener: 5 parts

[0044] Antioxidant: 0.7 parts

[0045]UV absorber: 0.6 parts

[0046] Nucleating agent: 0.2 parts

[0047] Anti-scratch agent: 0.5 parts

[0048] High-gloss masterbatch: 0.5 parts

[0049] In this example, on the basis of Example 1, 10 parts of precipitated barium sulfate masterbatches are added, and the number of parts of polypropylene resin is reduced to 85 parts. The raw materials are the same as in Example 1.

Embodiment 3

[0051] Polypropylene resin: 75 parts

[0052] Precipitated barium sulfate masterbatch: 20 parts

[0053] Toughener: 5 parts

[0054] Antioxidant: 0.7 parts

[0055] UV absorber: 0.6 parts

[0056] Nucleating agent: 0.2 parts

[0057] Anti-scratch agent: 0.5 parts

[0058] High-gloss masterbatch: 0.5 parts

[0059] In this example, on the basis of Example 1, 20 parts of precipitated barium sulfate masterbatches are added, and the content of polypropylene resin is reduced to 75 parts. The raw materials are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com