Silver-containing copper-based composite antibacterial coating material and preparation method thereof

A copper-based composite and antibacterial coating technology, which is applied in coatings, biocide-containing paints, antifouling/underwater coatings, etc., can solve the problems of poor wear resistance of antibacterial coatings, hindering drug efficacy, uneven drug distribution, etc. Problems, to achieve strong wear resistance, expand the scope of application, long-lasting effect of sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

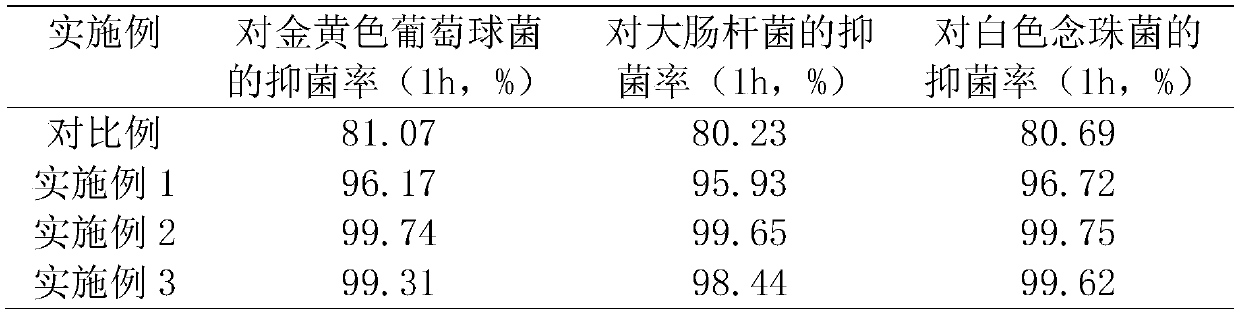

Examples

Embodiment 1

[0058] Example 1: Method 1 is used to prepare silver-containing copper-based composite antibacterial coating material

[0059] 1) Take a certain amount of micron silver powder, put it into the radio frequency induction plasma powder making equipment, heat the spheroidizing powder, add 20wt% absolute ethanol to the obtained powder, disperse it at high speed, and then classify it with a tube centrifuge 2- 3 times, finally the powder with good dispersibility is obtained and dried in a vacuum oven at 35-45℃ for later use;

[0060] 2) Take a certain amount of Ti(OH) 4 , Use radio frequency induction plasma to prepare nano titanium dioxide powder, add 20wt% absolute ethanol to the prepared powder, disperse it at high speed, and then use a tubular centrifuge to classify it for 2-3 times, and finally obtain a powder with good dispersion in 35- Dry in a vacuum oven at 45°C for later use;

[0061] 3) Preparation of silver-containing copper-based composite antibacterial coating material:

[006...

Embodiment 2

[0069] Example 2: Using method two to prepare silver-containing copper-based composite antibacterial coating material

[0070] 1) Take a certain amount of micron silver powder, put it into the radio frequency induction plasma powder making equipment, heat the spheroidizing powder, add 20wt% absolute ethanol to the obtained powder, disperse it at high speed, and then classify it with a tube centrifuge 2- 3 times, finally the powder with good dispersibility is obtained and dried in a vacuum oven at 35-45℃ for later use;

[0071] 2) Take a certain amount of TiO(OH) 2 , Use radio frequency induction plasma to prepare nano titanium dioxide powder, add 20wt% absolute ethanol to the prepared powder, disperse it at high speed, and then use a tubular centrifuge to classify it for 2-3 times, and finally obtain a powder with good dispersion in 35- Dry in a vacuum oven at 45°C for later use;

[0072] 3) Preparation of silver-containing copper-based composite antibacterial coating material:

[00...

Embodiment 3

[0080] Example 3: Method 3 is used to prepare silver-containing copper-based composite antibacterial coating material

[0081] 1) Take a certain amount of micron silver powder, put it into the radio frequency induction plasma powder making equipment, heat the spheroidizing powder, add 20wt% absolute ethanol to the obtained powder, disperse it at high speed, and then classify it with a tube centrifuge 2- 3 times, finally the powder with good dispersibility is obtained and dried in a vacuum oven at 35-45℃ for later use;

[0082] 2) Take a certain amount of TiO 2 , Use radio frequency induction plasma to prepare nano titanium dioxide powder, add 20wt% absolute ethanol to the prepared powder, disperse it at high speed, and then use a tubular centrifuge to classify it for 2-3 times, and finally obtain a powder with good dispersion in 35- Dry in a vacuum oven at 45°C for later use;

[0083] 3) Preparation of silver-containing copper-based composite antibacterial coating material:

[0084] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com