Preparation of two-dimensional layered WS by a molten salt electrochemical exfoliation method 2 material method

A two-dimensional layered, electrochemical technology, applied in the direction of electrolysis components, electrolysis process, etc., can solve the problems of limiting the size and layer distribution of two-dimensional materials, high reaction temperature, non-uniformity, etc., to improve electrochemical performance, process flow and so on. Simple, environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

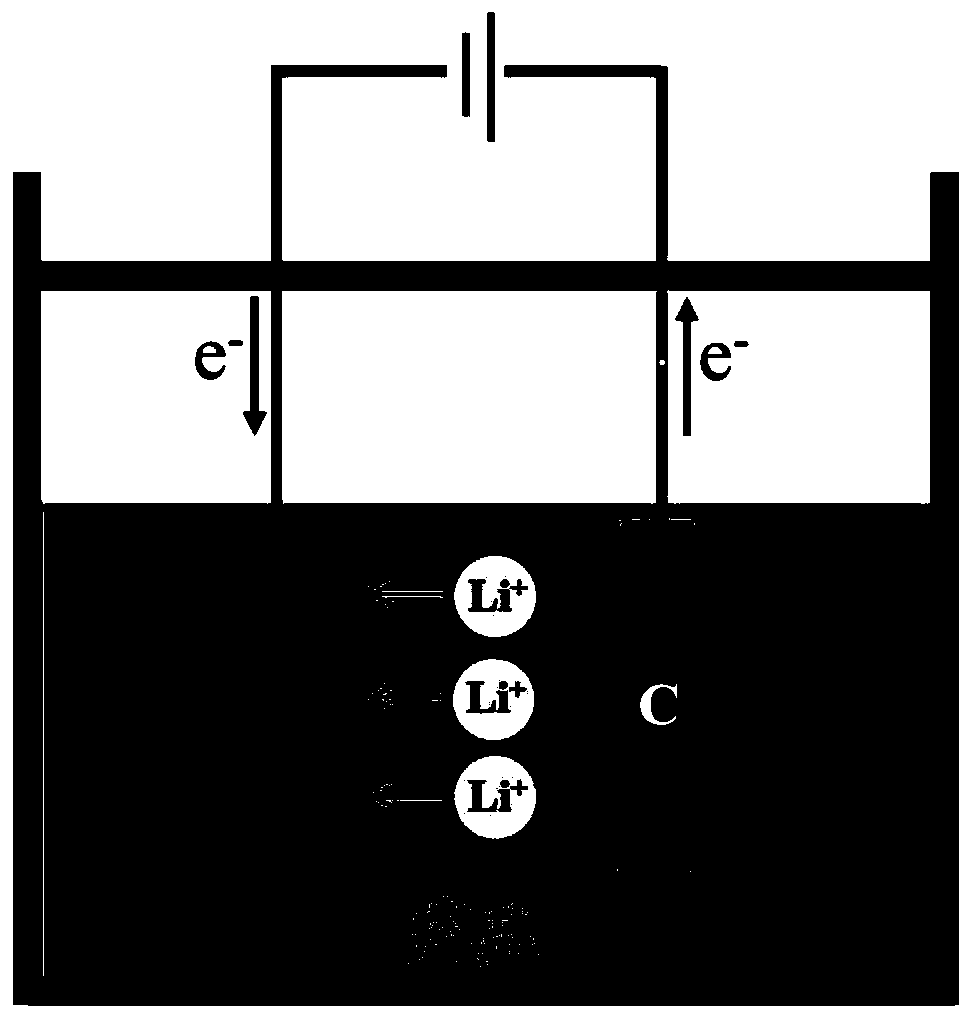

Method used

Image

Examples

Embodiment 1

[0056] Preparation of two-dimensional layered WS by a molten salt electrochemical exfoliation method 2 Material method, proceed as follows:

[0057] In this embodiment, the molten salt used is a chloride molten salt, specifically NaCl-CaCl 2 A mixture, by molar ratio, of NaCl:CaCl 2 =0.479:0.521.

[0058] Step 1: NaCl and CaCl 2 salt pretreatment

[0059] (1) NaCl and CaCl 2 Grinding separately to obtain NaCl powder with a particle size of 2 mm and CaCl powder with a particle size of 2 mm 2 Powder, respectively poured into beakers, and placed in a muffle furnace to seal;

[0060] (2) In a vacuum state, raise the temperature of the muffle furnace to 200-350 ° C and keep the temperature for 12 hours for pretreatment to remove the water in the molten salt, and then cool down to room temperature to take out the molten salt to obtain dehydrated NaCl and dehydrated salt respectively. After CaCl 2 ;

[0061] Step 2: Electrode Preparation

[0062] (1) 1gWS 2 The powder was ...

Embodiment 2

[0075] Preparation of two-dimensional layered WS by a molten salt electrochemical exfoliation method 2 Material method, proceed as follows:

[0076] In this embodiment, the molten salt used is a chloride molten salt, specifically a mixture of LiCl-KCl, in a molar ratio, LiCl:KCl=0.592:0.408.

[0077] Step 1: Pretreatment of LiCl and KCl salts

[0078] (1) Grind LiCl and KCl separately to obtain NaCl powder with a particle size of 2 mm and CaCl powder with a particle size of 2 mm 2 Powder, respectively poured into beakers, and placed in a muffle furnace to seal;

[0079] (2) In a vacuum state, raise the temperature of the muffle furnace to 300°C and keep the temperature constant for 12 hours for pretreatment to remove the water in the molten salt, and then cool down to room temperature to take out the molten salt to obtain dehydrated LiCl and dehydrated LiCl respectively. KCl;

[0080] Step 2: Electrode Preparation

[0081] (1) 1gWS 2 The powder was pressed into an electr...

Embodiment 3

[0092] Preparation of two-dimensional layered WS by a molten salt electrochemical exfoliation method 2 Material method, proceed as follows:

[0093] In this embodiment, the molten salt used is a chloride molten salt, specifically MgCl 2 -Mixture of NaCl-KCl, in molar ratio, MgCl 2 : NaCl: KCl = 0.454: 0.33: 0.216.

[0094] Step 1: MgCl 2 , NaCl and KCl salt pretreatment

[0095] With embodiment 1, difference is:

[0096] (1) In step 1, the MgCl 2 , NaCl and KCl grinding;

[0097] (2) In step 1, the MgCl after dehydration is obtained 2 , NaCl after dehydration and KCl salt after dehydration.

[0098] Step 2: Electrode Preparation

[0099] Identical with embodiment 1;

[0100] Step 3: Assembly of the reaction system

[0101] With embodiment 1, difference is:

[0102] (1) In (2) of step 3, the MgCl after 275g dehydration 2 , 122.75g of dehydrated NaCl and 102.25g of dehydrated KCl were put into a corundum crucible.

[0103] (2) In (3) of step 2, keep the vacuum at 200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com