Thermal-shock-resistant heat dissipation device based on phase change material

A phase change material, thermal shock resistance technology, applied in cooling/ventilation/heating transformation, sealed enclosures, etc., can solve the problems of device damage, increase in inverter loss, etc., to achieve the effect of optimizing the shape size and fully absorbing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment, what the present invention proposes is further introduced:

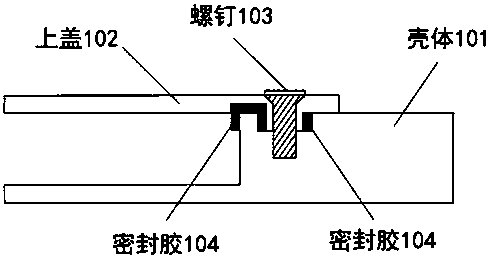

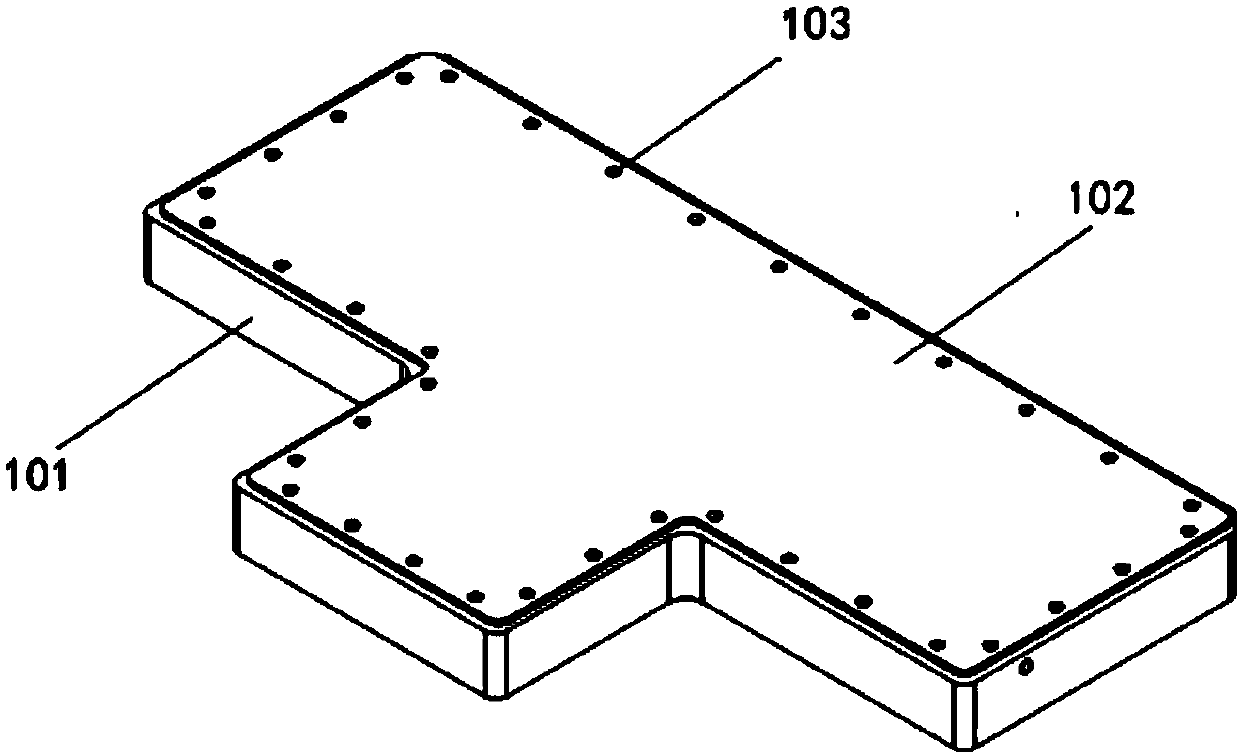

[0024] A thermal shock heat dissipation device based on phase change materials, including a housing 101, an upper cover 102, screws 103, ribs 106 and a heating device 108; wherein the upper cover 102 is fixed above the housing 101 by screws 103, the The heating device 108 is disposed in the casing 101 , and a large number of ribs 106 are laid on the heating device 108 .

[0025] A sealing groove 105 is formed on the edge of the housing 101 .

[0026] The edge of the upper cover 102 is provided with a ring of protrusions, and the protrusions are stuck in the sealing groove 105 .

[0027] A sealant 104 is injected between the sealing groove 105 and the edge boss of the upper cover 102 .

[0028] The protruding dimension of the edge of the upper cover 102 is slightly narrower than the sealing groove 108 .

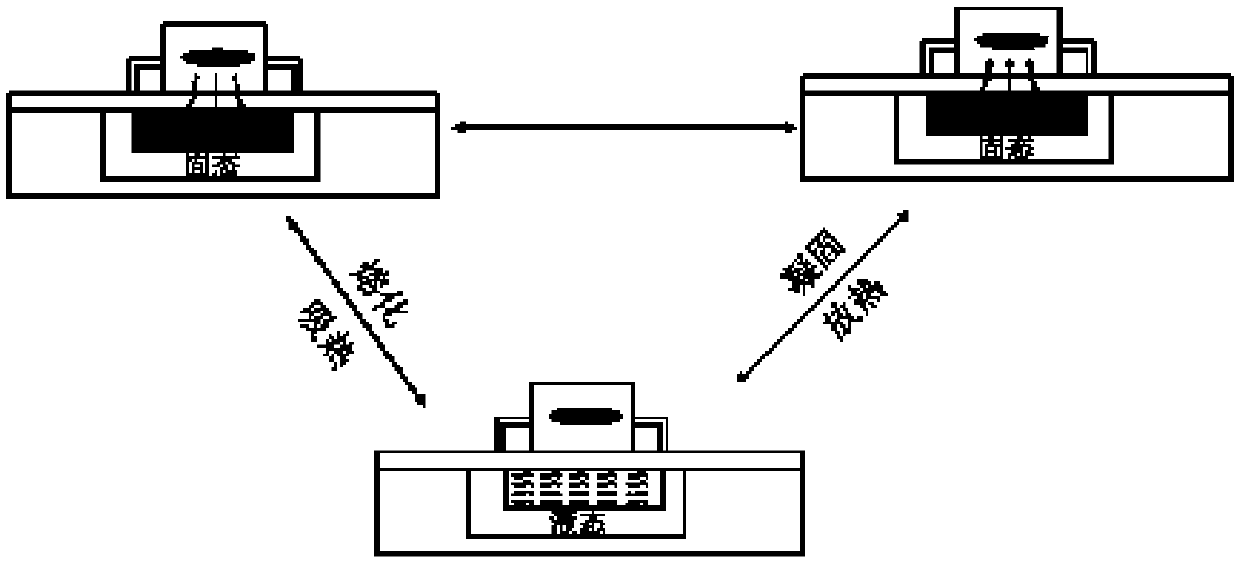

[0029] The inner cavity of the sealed dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com