Porous lanthanum oxide preparation method

A technology of lanthanum oxide and 3·6H2O, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the serious eutrophication of water bodies, destroy the ecological environment of water bodies, and threaten the survival of aquatic organisms and human beings Health and other issues, to achieve the effect of saving energy, solving eutrophication, improving survival and human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

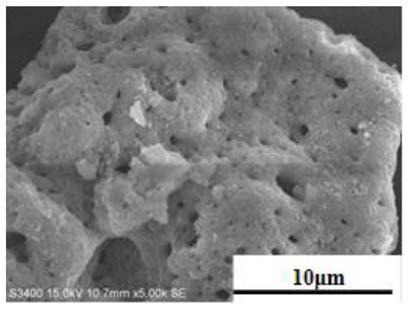

Embodiment 1

[0025] The preparation method of porous lanthanum oxide comprises the following steps:

[0026] Step (1): Add 0.1mol 11.1mL N-methylmorpholine and 0.12mol 13.8mL benzyl chloride into a three-necked flask respectively, heat at 45°C with a magnetic stirrer for 45min to obtain a mixture; filter the mixture with suction , washed twice with ether to obtain the N-methyl-N benzylmorpholine ionic liquid, and the N-methyl-N benzylmorpholine ionic liquid was stored in a desiccator.

[0027] Step (2): Weigh 0.4397g La(NO 3 ) 3 ·6H 2 O and 0.1047g glycerin are respectively placed in the reactor, respectively add deionized water in the reactor, obtain La(NO 3 ) 3 ·6H 2 O solution and glycerol solution;

[0028] Step (3): Add 0.1g of N-methyl-N-benzylmorpholine ionic liquid prepared in step (1) and 1mL of 0.01mol / L polyethylene glycol to the reactor filled with glycerin solution in step (2). Alcohol to obtain mixed solution A;

[0029] Step (4): La(NO 3 ) 3 ·6H 2 Mixed solution A...

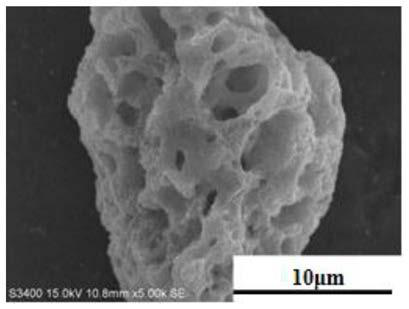

Embodiment 2

[0032] The preparation method of porous lanthanum oxide comprises the following steps:

[0033] Step (1): Add 0.1mol 11.1mL N-methylmorpholine and 0.12mol 13.8mL benzyl chloride into a three-necked flask respectively, heat at 45°C with a magnetic stirrer for 45min to obtain a mixture; filter the mixture with suction , washed twice with ether to obtain the N-methyl-N benzylmorpholine ionic liquid, and the N-methyl-N benzylmorpholine ionic liquid was stored in a desiccator.

[0034] Step (2): Weigh 0.4397gLa(NO 3 ) 3 ·6H 2 O and 0.1047g glycerin are respectively placed in the reactor, respectively add deionized water in the reactor, obtain La(NO 3 ) 3 ·6H 2 O solution and glycerol solution;

[0035] Step (3): Add 0.2g of N-methyl-N-benzylmorpholine ionic liquid prepared in step (1) and 1mL of 0.01mol / L polyethylene glycol to the reactor filled with glycerin solution in step (2). Alcohol to obtain mixed solution A;

[0036] Step (4): La(NO 3 ) 3 ·6H 2 Mixed solution A ...

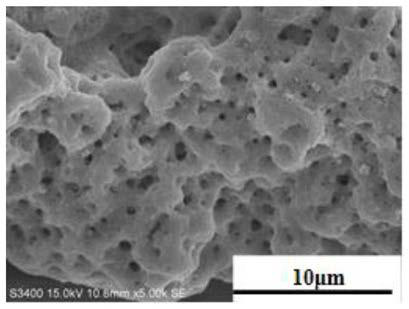

Embodiment 3

[0039] The preparation method of porous lanthanum oxide comprises the following steps:

[0040] Step (1): Add 0.1mol 11.1mL N-methylmorpholine and 0.12mol 13.8mL benzyl chloride into a three-necked flask respectively, and heat with a magnetic stirrer at 45°C for 45min to obtain mixture A; Filtrate with suction, wash twice with ether to obtain N-methyl-N-benzylmorpholine ionic liquid, and store the N-methyl-N-benzylmorpholine ionic liquid in a desiccator.

[0041] Step (2): Weigh 0.4397gLa(NO 3 ) 3 ·6H 2 O and 0.1047g glycerin are respectively placed in the reactor, respectively add deionized water in the reactor, obtain La(NO 3 ) 3 ·6H 2 O solution and glycerol solution;

[0042] Step (3): Add 0.3g of N-methyl-N-benzylmorpholine ionic liquid and 1mL of 0.01mol / L polyethylene glycol prepared in step (1) to the reactor filled with glycerin solution in step (2) Obtain mixed solution A;

[0043] Step (4): La(NO 3 ) 3 ·6H 2 Mixed solution A in O solution and step (3) is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com