High-efficiency adsorption and dearomatization modified activated carbon and preparation method thereof

A technology of activated carbon and modification, which is applied in the direction of chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve problems that cannot meet practical applications, and achieve the purpose of improving the selective adsorption of aromatic amino acids by activated carbon, Effect of reducing adsorption loss and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Prepare a mixed solution of free amino acids containing leucine, isoleucine, valine, phenylalanine, and tyrosine at a concentration of 5 mmol / L, respectively.

[0036] Preparation of modified activated carbon: HNO with concentrations of 3, 4, 5, 6, 8, 10mol / L 3 Add granular activated carbon to the solution at a carbon-to-liquid ratio (g / mL) of 1:5 and soak for 20 hours, then wash with deionized water to pH 5.0-6.0, and dry in an oven at 105°C to obtain modified activated carbon.

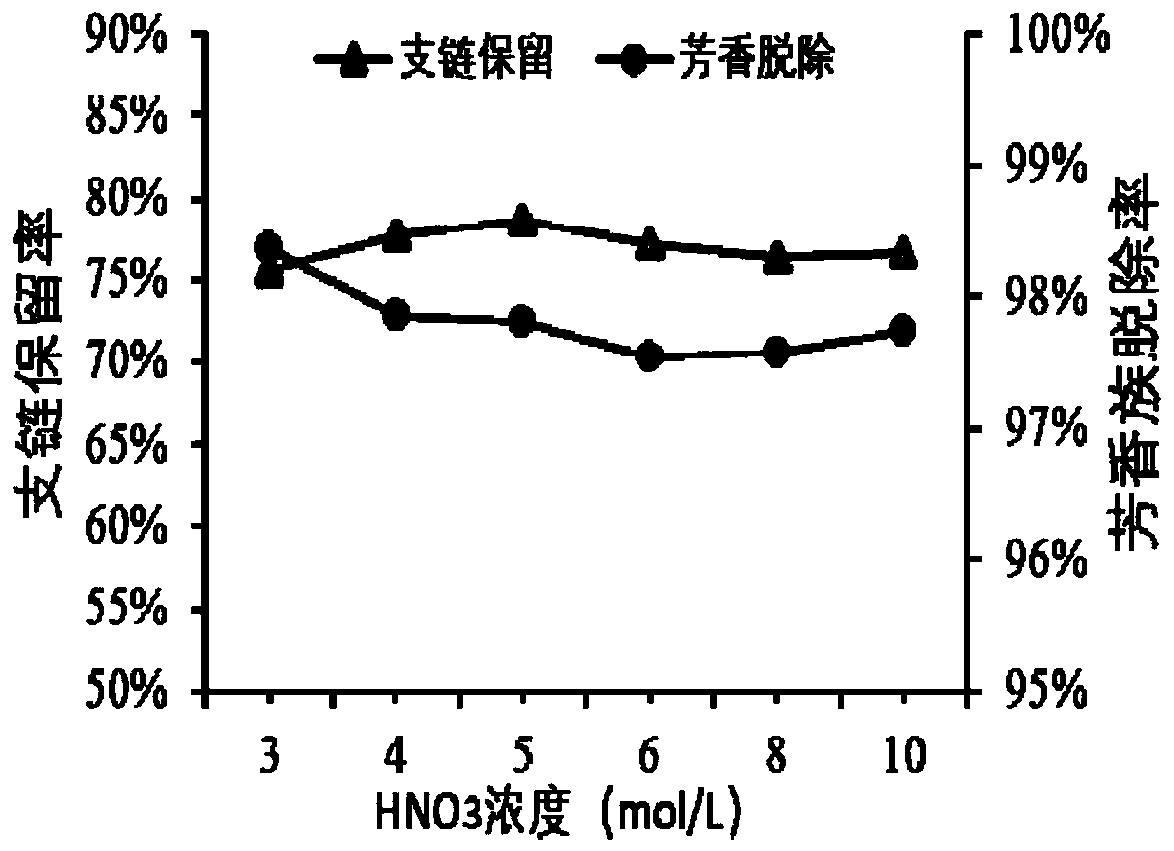

[0037] Add 100g / L activated carbon prepared under the above conditions to the mixed amino acid solution, and adsorb for 2 hours at pH 2.0-3.0, temperature 55°C, and measure the branched chain retention rate and aromatic amino acid removal rate. The results show that (Such as figure 1 ), 3-5mol / L nitric acid solution modified activated carbon can make the branched chain retention rate reach 75-80%, and the aromatic amino acid removal rate reach 97-99%.

Embodiment 2

[0039] The specific embodiment is the same as in Example 1, the difference is that the concentration is divided into 0.05,0.1,0.5,1,5,10mol / L of H 2 SO 4 Solution replacement HNO 3 solution.

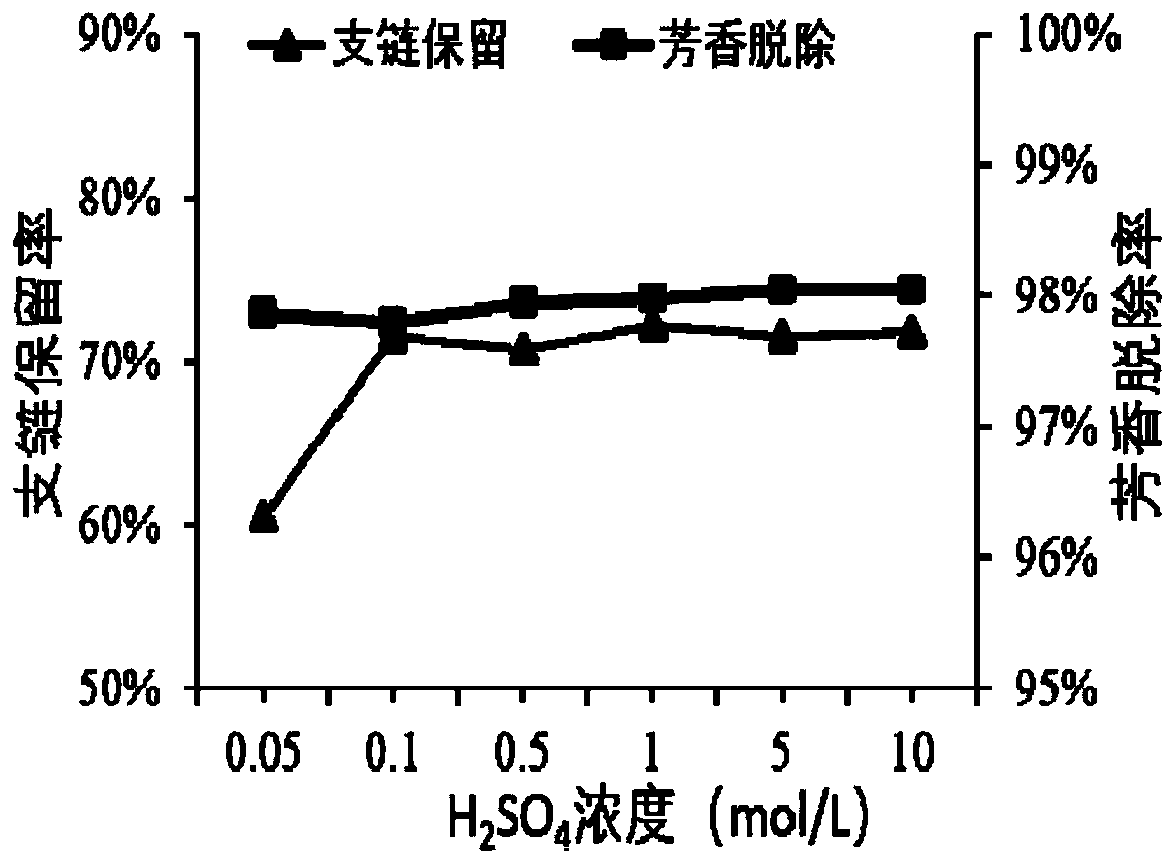

[0040] The branched chain retention rate and the aromatic amino acid removal rate of the solution after the modified activated carbon treatment were measured, and the results showed (such as figure 2 ), the concentration is 0.1~10mol / L of H 2 SO 4 Solution modified activated carbon can make the branched chain retention rate reach 70-75%, and the removal rate of aromatic amino acid reach 97-98%.

Embodiment 3

[0042] The specific embodiment is the same as in Example 1, the difference is that HNO is replaced by HCl solutions with concentrations of 0.05, 0.1, 0.5, 1, 5, and 10 mol / L respectively 3 solution.

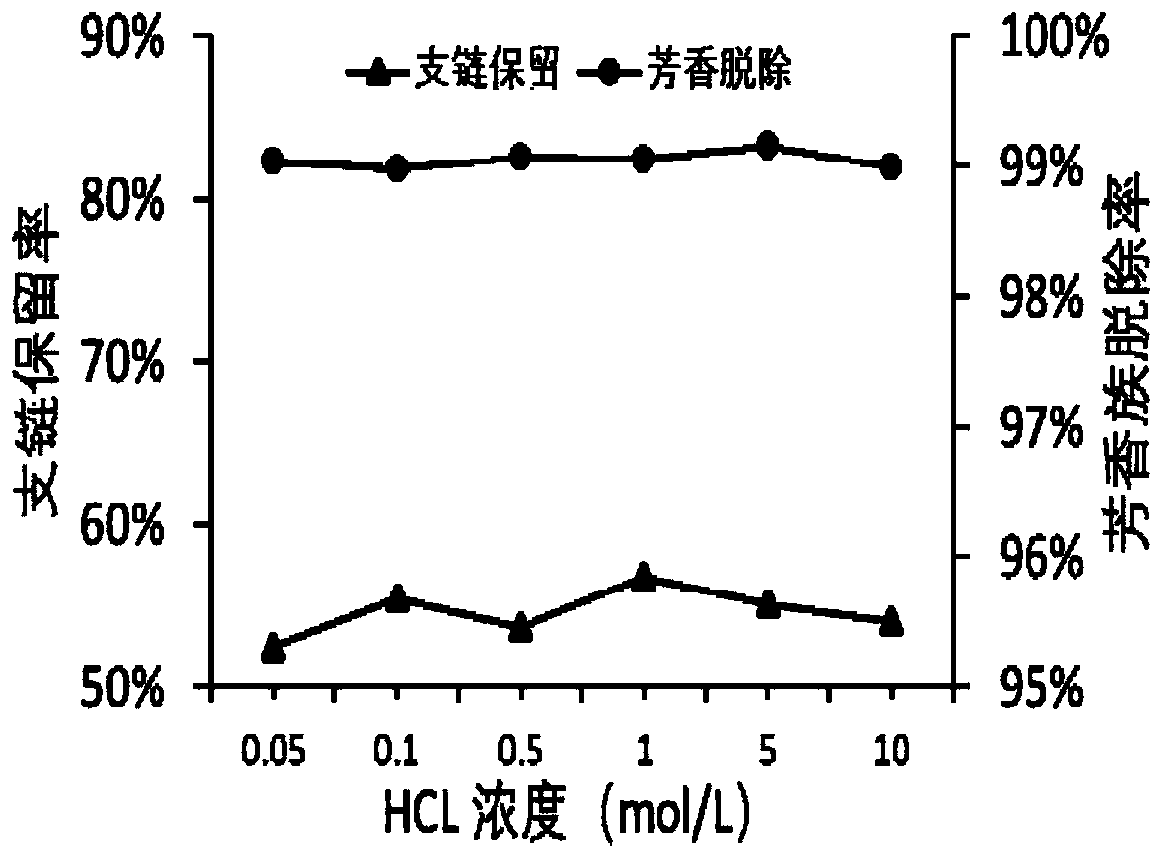

[0043] The branched chain retention rate and the aromatic amino acid removal rate of the solution after the modified activated carbon treatment were measured, and the results showed (such as image 3 ), the HCl solution with a concentration of 1mol / L has a relatively good effect of modifying activated carbon, which can make the branched chain retention rate reach 58%, and the aromatic amino acid removal rate reach 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com