Flowing injection disconnected eight-way valve adsorption preenrichment elution method

A technology of flow injection and elution method is applied in the field of combined use of flow injection braided reactor and flame atomic absorption spectrometer, which can solve the problems of many adsorption losses, losses, etc., so as to reduce adsorption loss, lower detection limit, and improve concentration The effect of coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Instruments and reagents

[0043] (1) WFX-210 atomic absorption spectrometer: Beijing Ruili Analytical Instrument Co., Ltd., the measurement wavelength of cadmium is 228.8nm; the acetylene flow rate is 1.5L / min, the air flow rate is 7.0L / min; the slit width is 0.2nm, the sample The lifting rate is 10.0mL / min, the reading mode is continuous, and the reading interval is 0.5s;

[0044] IFIS-D Flow Injection Analyzer: Xi'an Ruimai Analytical Instrument Co., Ltd.

[0045] Braided reactor material: polytetrafluoroethylene, inner diameter 0.5mm, outer diameter 1.0mm, braided along one direction;

[0046] pHS-3C pH meter: Shanghai Yidian Scientific Instrument Co., Ltd.;

[0047] PL3002 electronic balance: Mettler-Toledo Instruments (Shanghai) Co., Ltd.

[0048] (2) Nitric acid, hydrochloric acid, ammonia water, absolute ethanol, dimethylglyoxime and 8-hydroxyquinoline (8-HQ, superior grade): Guangzhou Chemical Reagent Factory;

[0049] Sodium diethyldithiocarbamate (DDTC...

Embodiment 2

[0089] This embodiment is similar to the steps of Embodiment 1, the difference is that the steps of this embodiment are:

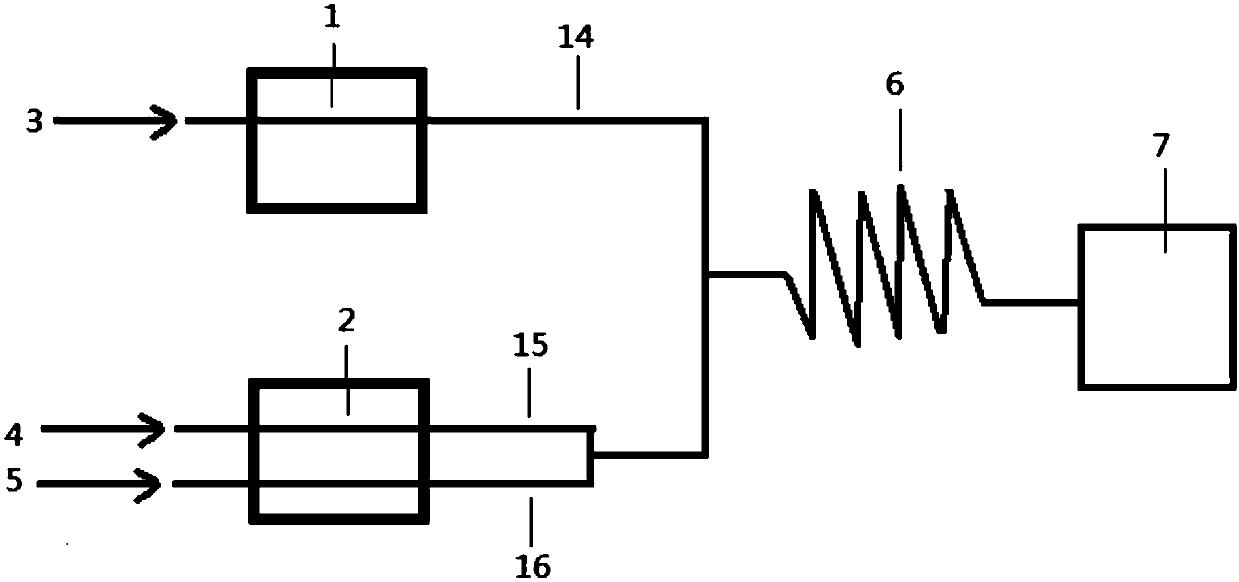

[0090] (1) if figure 1 As shown, the pump 1 and the pump 2 are turned on, and the sample solution 3 to be tested or the standard solution of cadmium, the complexing agent solution 4 and the air flow 5 are input into the weaving reactor 6 . Cd 2+ React with the complexing agent online, and the complex is adsorbed on the inner wall of the braided reactor 6 by the centrifugal force of the braided reactor 6, and the duration is 70s.

[0091] (2) Stop pump 1 and pump 2, and take out tubes 15 and 16 for 2 s.

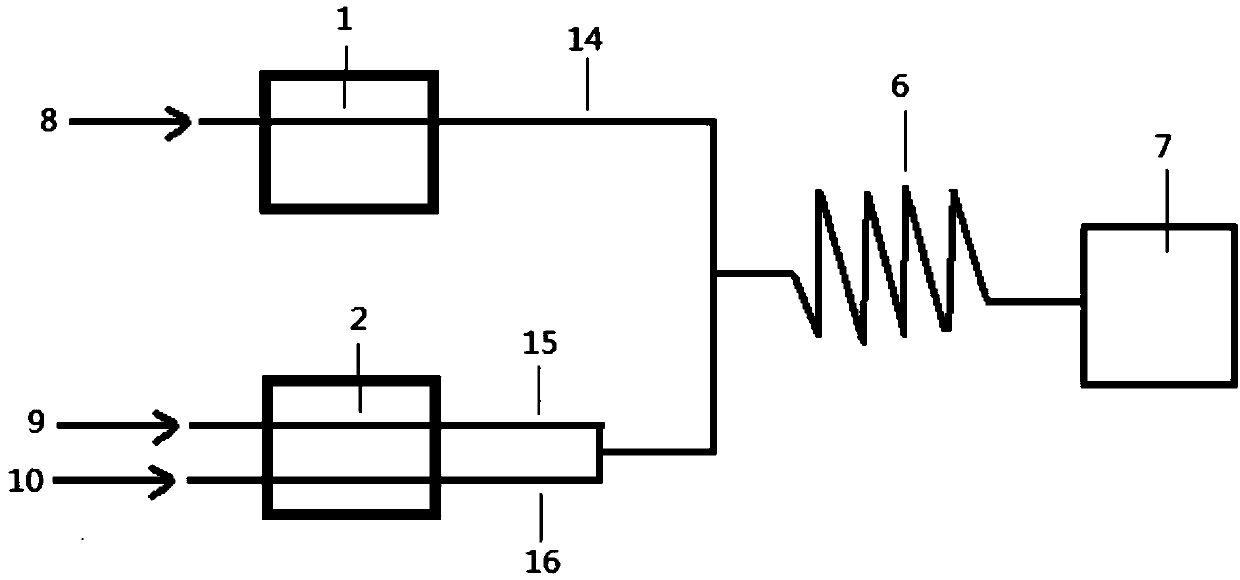

[0092] (3) if figure 2 As shown, pump 1 and pump 2 are turned on for 25s. The air flow 8, 9 and 10 is input into the braiding reactor 6, and the remaining sample solution 3 to be tested or the standard solution of cadmium and the complexing agent solution 4 in the pipes 15 and 16 are emptied.

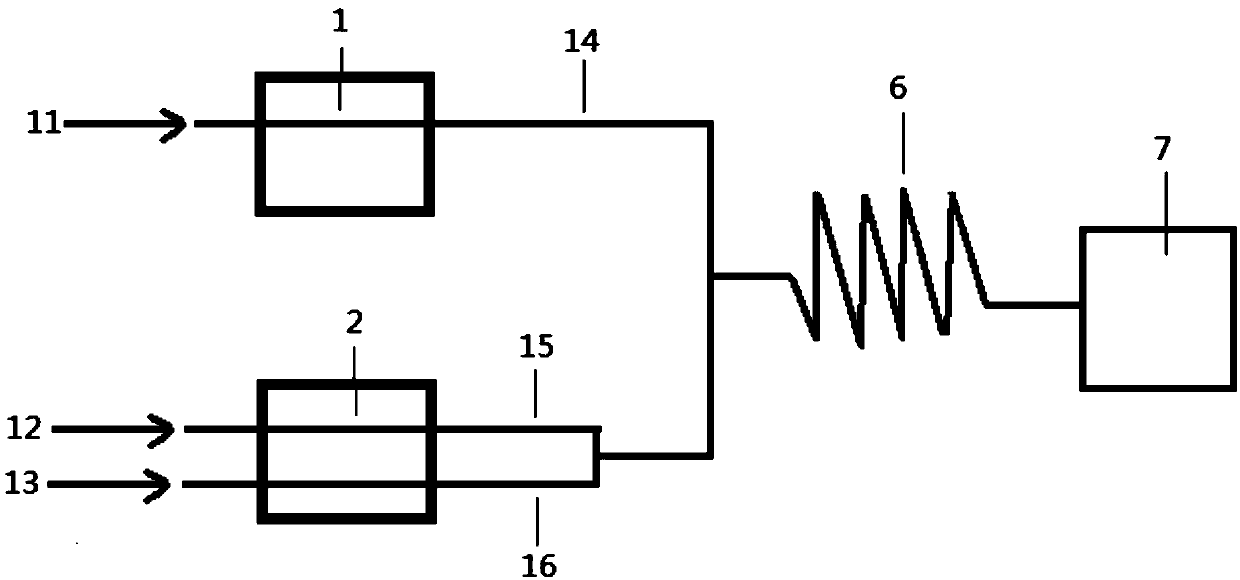

[0093] (4) Stop pump 1 and pump 2, put tubes 14, 15 and ...

Embodiment 3

[0101] This embodiment is similar to the steps of Embodiment 1, the difference is that the steps of this embodiment are:

[0102] (1) if figure 1 As shown, the pump 1 and the pump 2 are turned on, and the sample solution 3 to be tested or the standard solution of zinc, the complexing agent solution 4 and the air flow 5 are input into the weaving reactor 6 . Zn 2+ React with the complexing agent online, and the complex is adsorbed on the inner wall of the braided reactor 6 by the centrifugal force of the braided reactor 6, and the duration is 60s.

[0103] (2) Stop pump 1 and pump 2, and take out tubes 15 and 16 for 2 s.

[0104] (3) if figure 2 As shown, pump 1 and pump 2 are turned on for 30s. The air flow 8, 9 and 10 is input into the braiding reactor 6, and the remaining sample solution 3 to be tested or the standard solution of zinc and the complexing agent solution 4 in the pipes 15 and 16 are emptied.

[0105] (4) Stop pump 1 and pump 2, put tubes 14, 15 and 16 int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com