Microporous extrusion grinding machine tool

A technology of extrusion grinding and machine tools, which is applied in the directions of grinding machine parts, grinding machines, and machine tools suitable for grinding the edges of workpieces. Ensure the effect of coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

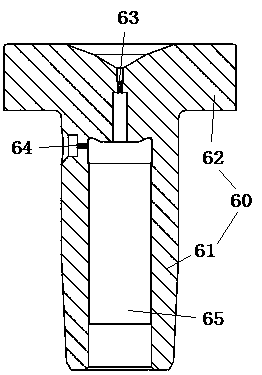

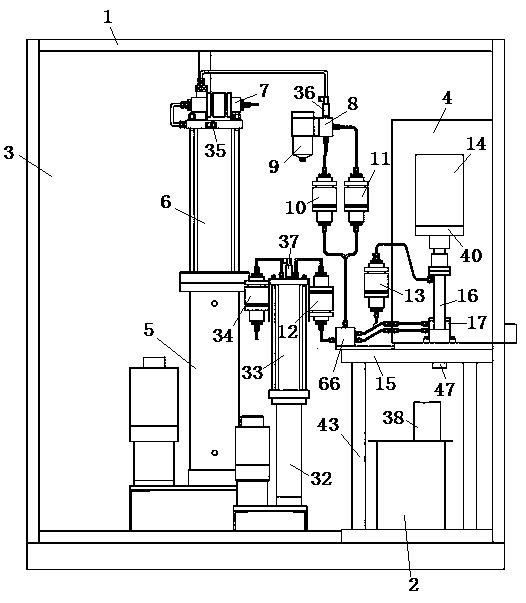

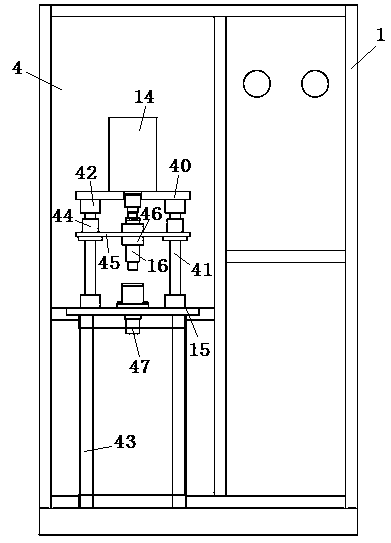

[0038] Embodiment 1: as figure 2 , 3 , 4, 5, and 6, a microporous extrusion grinding machine tool includes a frame 1, an abrasive bucket 2, a material suction system, a filtration system, an oil switching system and a clamp assembly; the frame 1 includes a power part 3 and the operating part 4, a door is installed on one side of the power part 3, and one side of the operating part 4 is open;

[0039] The suction system includes a large servo electric cylinder 5, a suction cylinder 6 and a solenoid valve VI7; the large servo electric cylinder 5 is installed in the power part 3 through a bracket, and the top end of the piston rod of the large servo electric cylinder 5 is fixedly connected by bolts There is a piston; the suction cylinder 6 is fixedly connected to the top of the large servo electric cylinder 5 by bolts, and an O-shaped sealing ring is arranged between the suction cylinder 6 and the large servo electric cylinder 5, and the end of the large servo electric cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com