3D printing device for powder material light-curing bonding and printing method

A powder material and 3D printing technology, applied in the field of 3D printing, can solve the problems of fragile molded parts and workpiece deformation, achieve high molding efficiency, fast and efficient printing, and expand the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

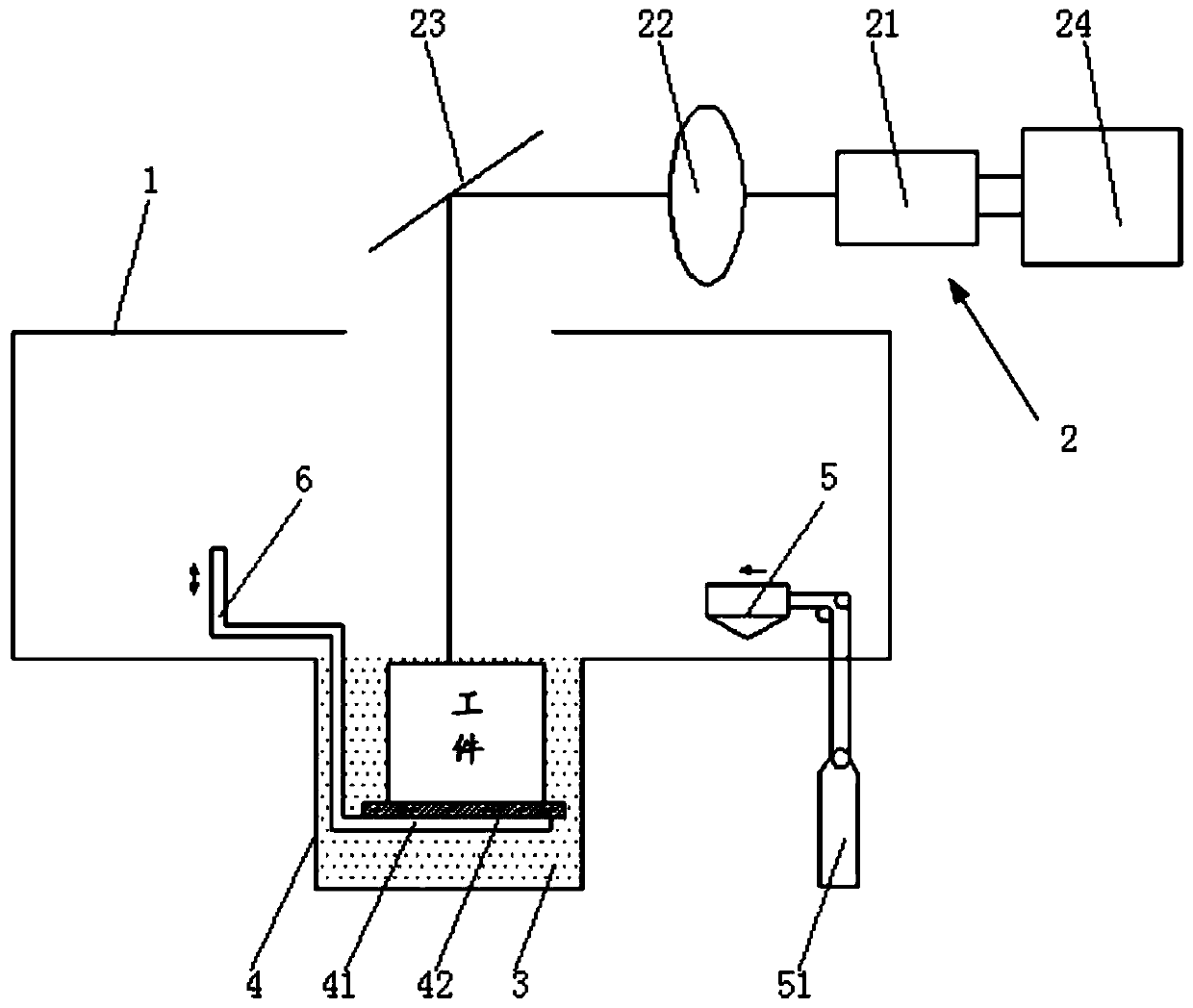

[0040] Such as figure 1 As shown, the lifting device is a lifting platform 6, one end of the lifting platform 6 is connected with the side of the base 41, and the other end is connected with a motor, and the motor is controlled by a computer for precise lifting.

example 2

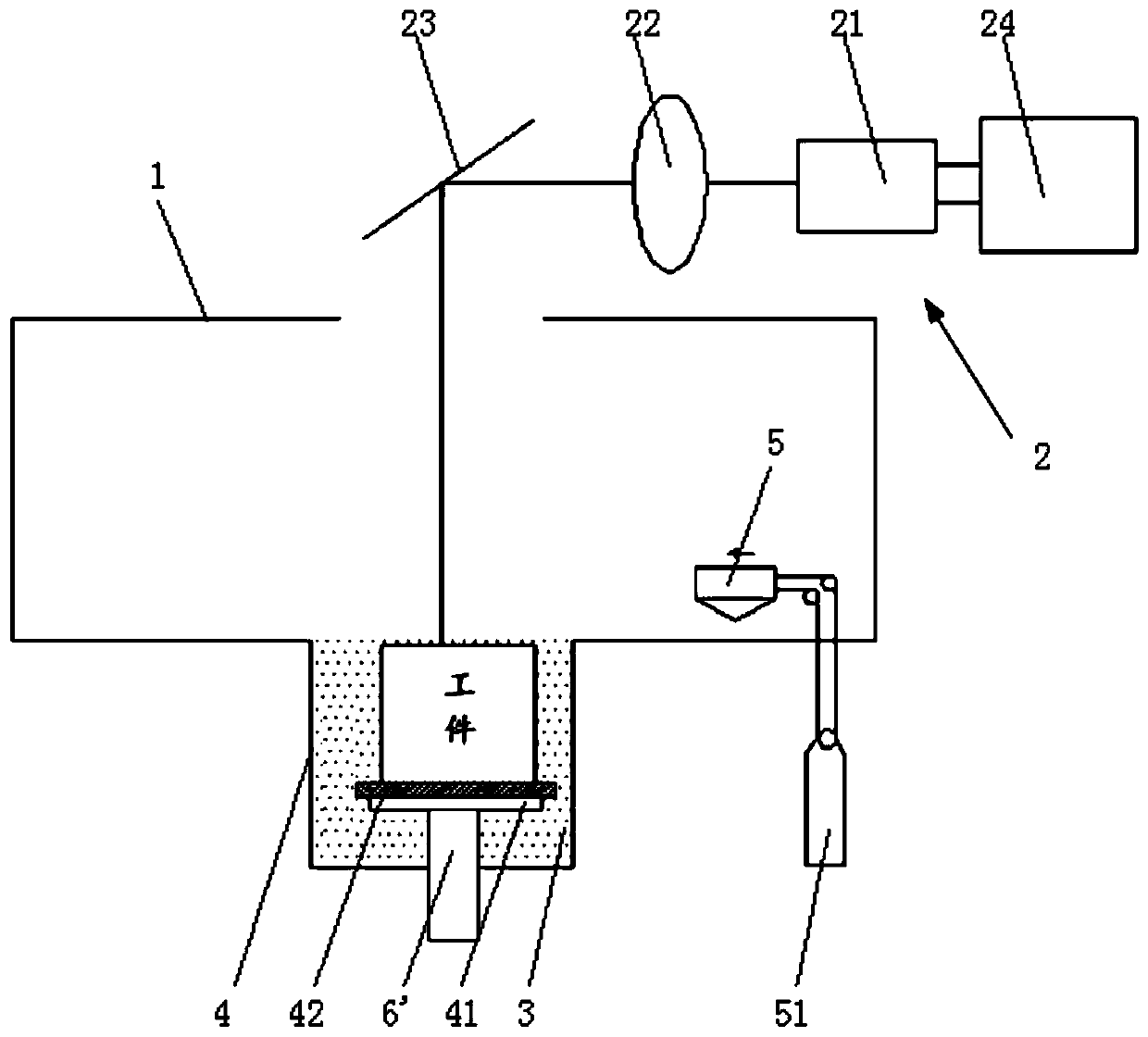

[0042] Such as figure 2 As shown, the lifting device is a piston 6', one end of the piston 6' is connected to the bottom surface of the base 41, and the other end stretches out from the bottom of the photosensitive liquid pool 4 and is connected to a motor, the lifting of the piston is controlled by the motor, and the piston 6' is connected to the photosensitive liquid pool 4 There is a sealing device at the joint to prevent leakage of photosensitive liquid.

[0043] Further, the molding cavity 1 is a shell structure with an upper end open, and at this time, the scanning system 23 is located above the opening of the molding cavity.

[0044] On the other hand, an embodiment of the present invention provides a method for printing a 3D printing device with light-cured and bonded powder materials, the method comprising the following steps:

[0045] Step 1: Place the substrate 42 on the base 41 and fix it properly, and adjust the lifting device so that the substrate 42 is at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com