Electric vehicle

A technology of electric vehicles and automobiles, which is applied in the direction of electric vehicles, electric vehicle charging technology, charging stations, etc., can solve the problems of difficult mechanical operation of battery replacement, idle battery resources, and inability to realize plug-and-play of battery packs, etc., and achieve partial The effect of strong temperature distribution consistency and small number of cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

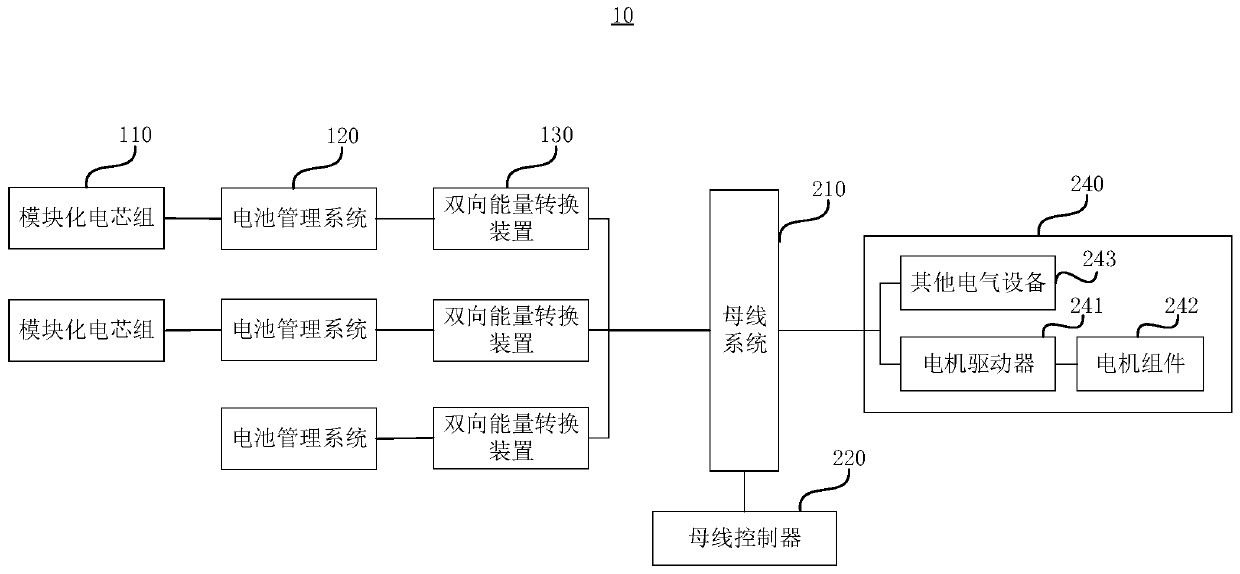

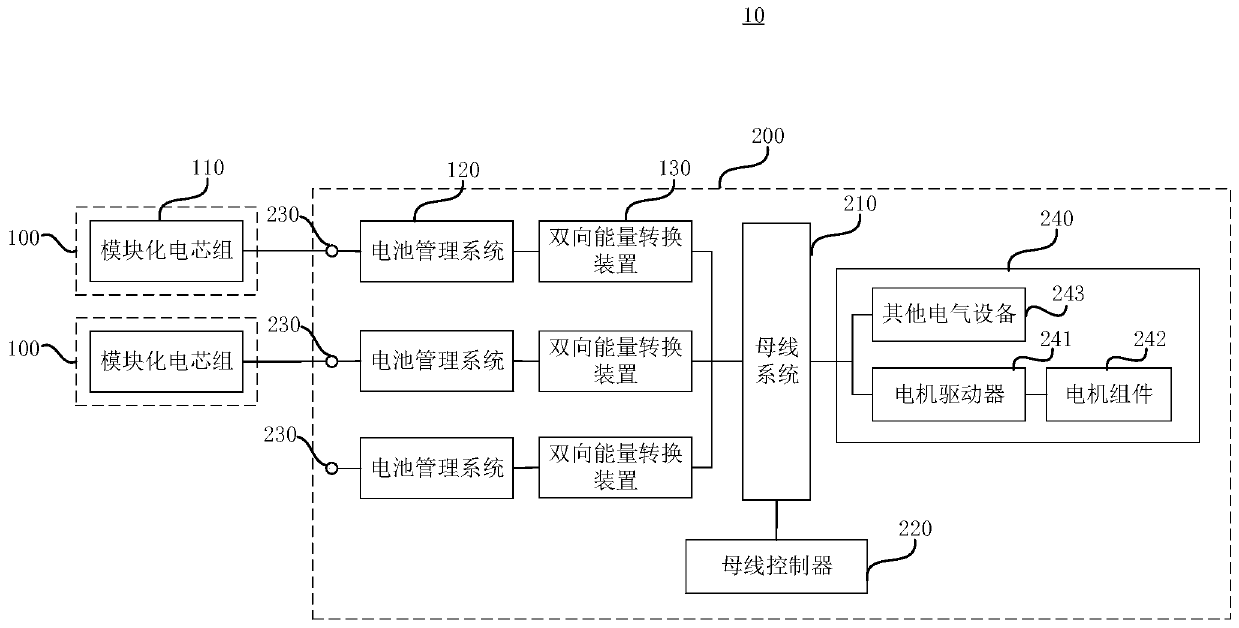

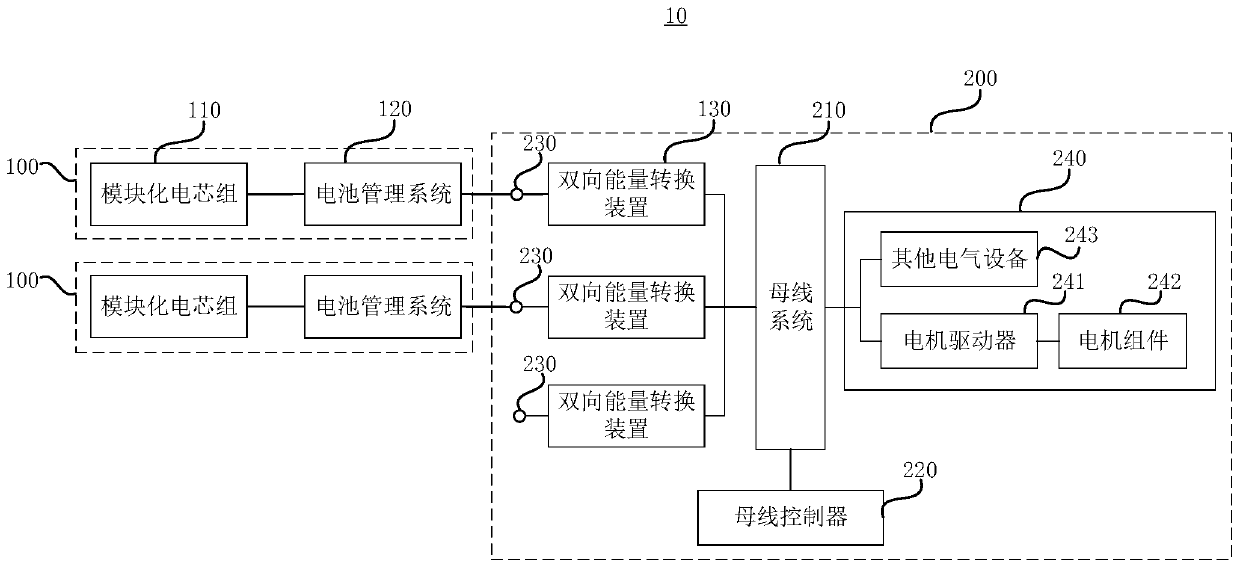

[0040] The present invention provides an electric vehicle 10. The electric vehicle 10 includes a vehicle electrical equipment 240, a bus system 210, a bus controller 220, a plurality of bidirectional energy conversion devices 130, a plurality of battery management systems 120 and at least one modular electric vehicle. core pack 110 .

[0041] Each modular battery pack 110 is electrically connected to the battery management system 120 and the bidirectional energy conversion device 130 in turn, and then electrically connected to the bus system 210, so as to output the energy stored in the modular battery pack 110 to the bus system 210 for further processing. discharge, or reversely store the energy in the busbar system 210 to the modular battery pack 110 for charging. The battery management system 120 is used to control the working state of the modular battery core set 110, and the bidirectional energy conversion device 130 is used to convert the energy between the modular batte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com