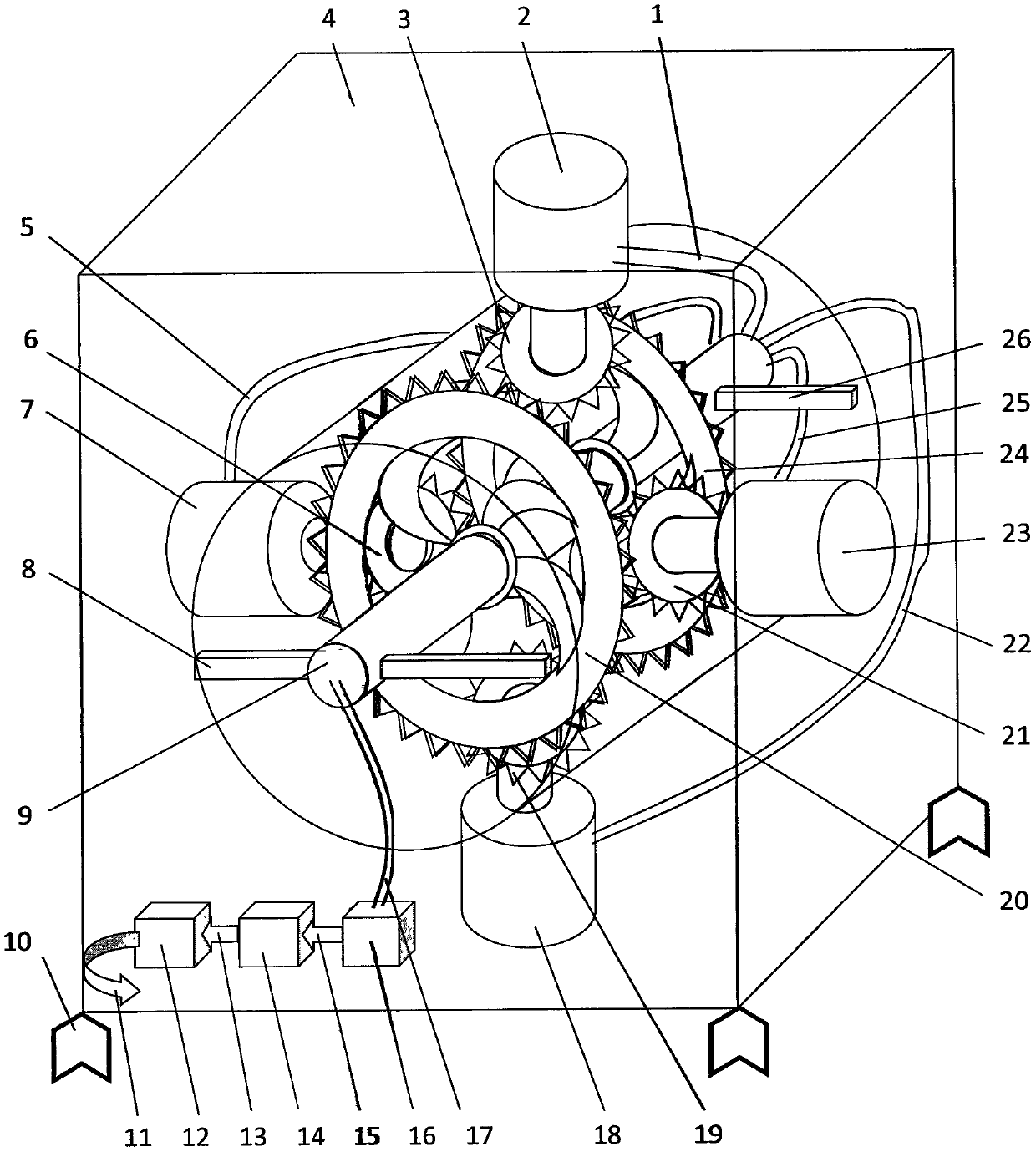

Double spiral blade type deep sea medium and small-sized seawater desalinizer

A small and medium-sized, double-helix technology, applied in seawater treatment, general water supply conservation, chemical instruments and methods, etc., can solve problems such as strict water quality requirements and poor adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

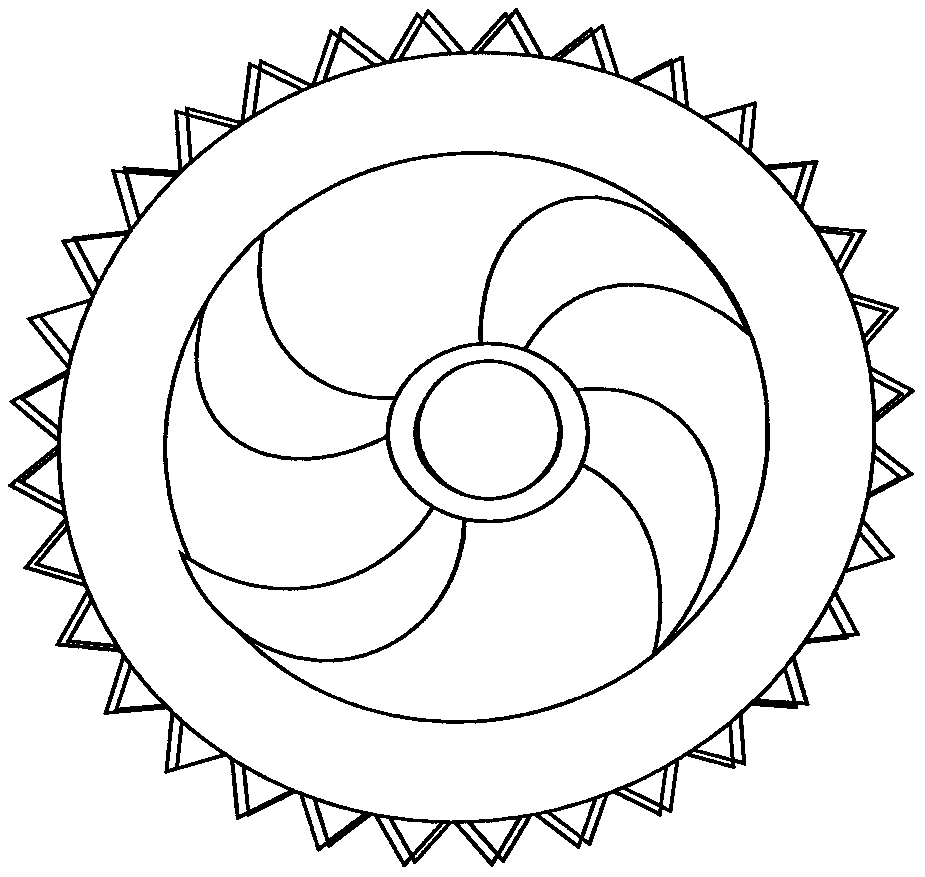

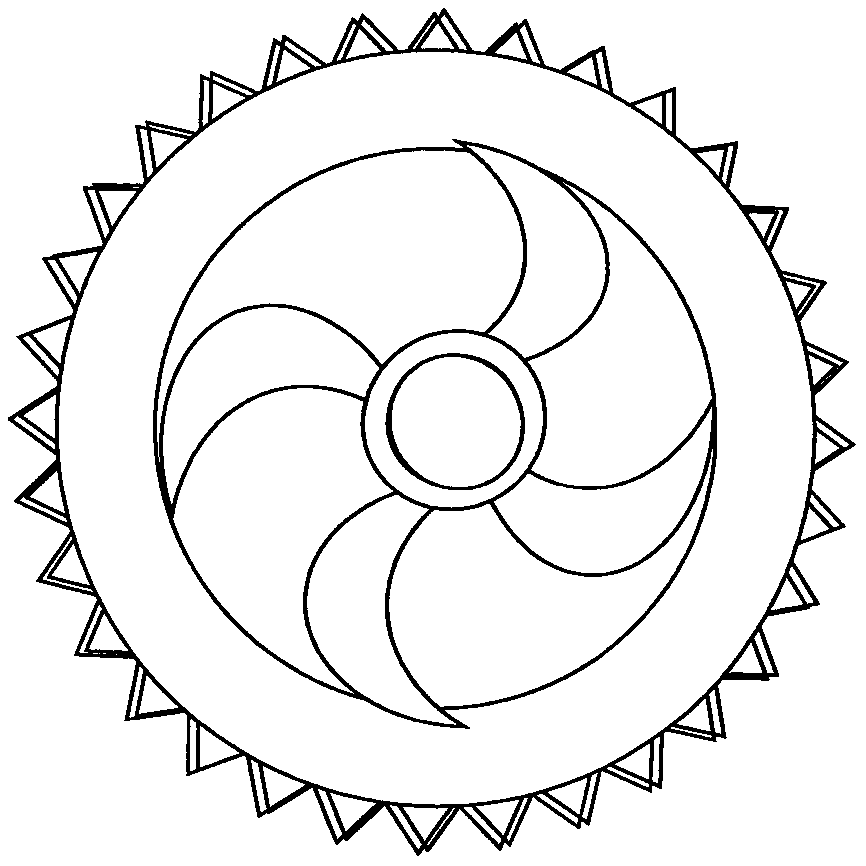

[0020] The specific embodiment of the present invention is, the hollow pretreatment filter case 4 is set, and the water inlets at the bottom of booster pump I 2, booster pump II 7, booster pump III 18 and booster pump IV 23 are respectively connected to the hollow pretreatment The upper water outlet, the left water outlet, the lower water outlet and the right water outlet are processed inside the filter box 4, and the water outlets of the booster pump I2, the booster pump II7, the booster pump III18 and the booster pump IV23 are connected to the water outlet respectively. Water pipe I 1, water pipe II 5, water pipe III 22 and water pipe IV 25, the other end of water pipe I 1, water pipe II 5, water pipe III 22 and water pipe IV 25 is connected to the reverse osmosis semi-permeable membrane assembly shaft 9 water inlet, and then set ultraviolet sterilizer 16, ozone sterilizer 14 and water storage tank 12, and ultraviolet sterilizer 16, ozone sterilizer 14 and water storage tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com