Method for recovering copper and zinc element in copper soot by microwave reduction roasting-sulfuric acid leaching

A technology for recovering copper and copper soot, which is applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of complex processing technology, achieve the effects of lower process temperature, faster heating rate, and lower recycling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

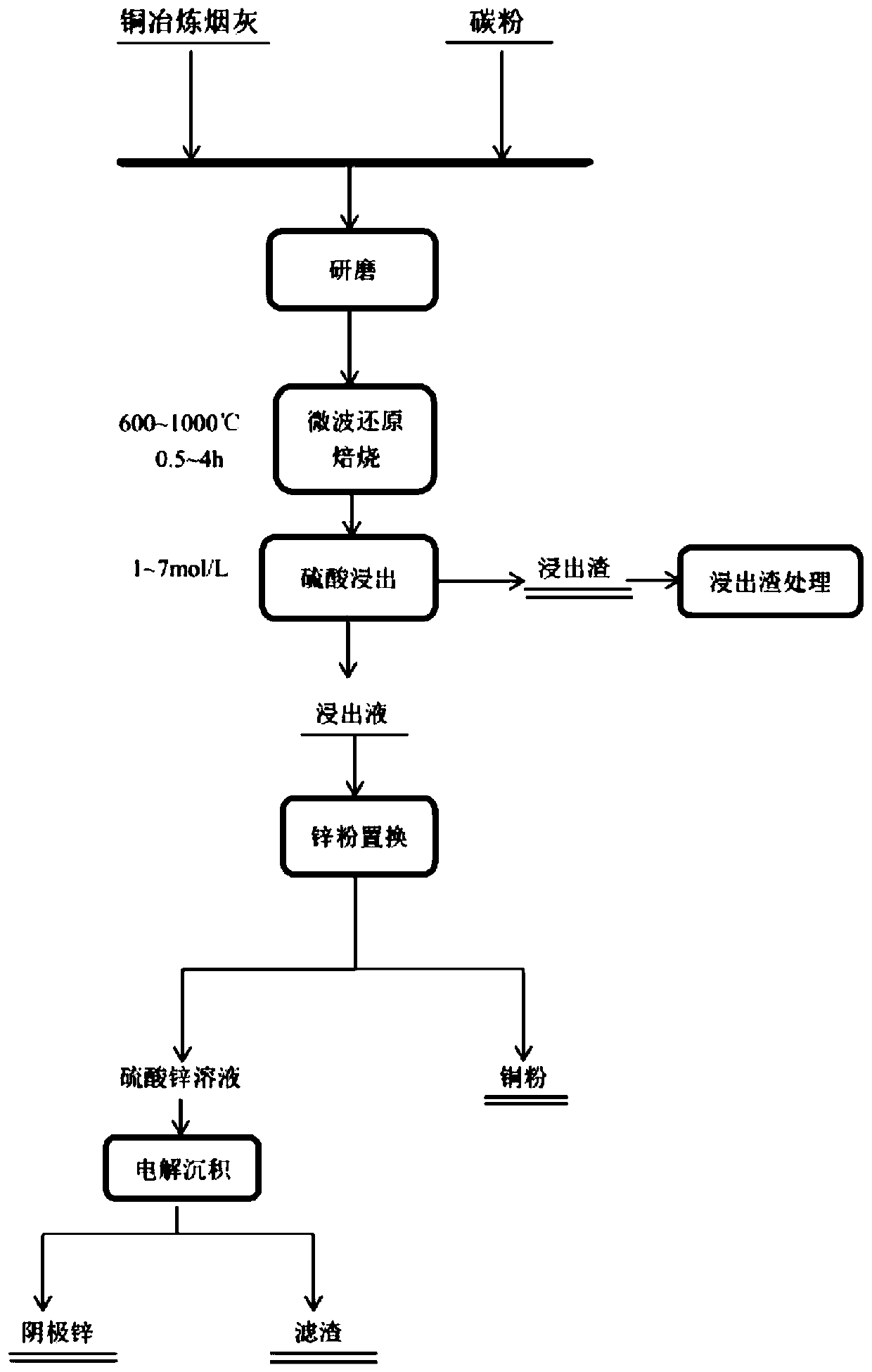

[0034] combine figure 1 , a method of microwave reduction roasting-sulfuric acid leaching of the present embodiment reclaims copper and zinc elements in copper soot, comprising the following steps:

[0035] Step 1. Microwave reduction roasting:

[0036] Copper soot and carbon with 10% of the total amount of copper soot were mixed and ground for 5 minutes, and then put into a microwave oven for carbon thermal reduction roasting for 2 hours at a roasting temperature of 750°C.

[0037] Step 2, sulfuric acid leaching of copper and zinc:

[0038] The leaching is carried out in a 500ml three-hole boiler, heated by a water bath, and the water bath is turned on to set a predetermined temperature for preheating. Add it into a three-hole flask, connect an electric stirrer, and when the temperature of the thermocouple reaches the temperature required for the experiment, quickly pour in the weighed copper soot (5g), turn on the stirrer, observe the temperature change of the thermocouple...

Embodiment 2

[0042] A method of microwave reduction roasting-sulfuric acid leaching of the present embodiment reclaims copper and zinc elements in copper soot, comprising the following steps:

[0043] Step 1. Microwave reduction roasting:

[0044] Copper soot and carbon with 5% of the total amount of copper soot were mixed and ground for 8 minutes, and then put into a microwave oven for carbon thermal reduction roasting for 0.5 hour at a roasting temperature of 900°C.

[0045] Step 2, sulfuric acid leaching of copper and zinc:

[0046] The leaching is carried out in a 500ml three-hole boiler, heated by a water bath, and the water bath is turned on to set a predetermined temperature for preheating. Add it into a three-hole flask, connect an electric stirrer, and when the temperature of the thermocouple reaches the temperature required for the experiment, quickly pour in the weighed copper soot (5g), turn on the stirrer, observe the temperature change of the thermocouple, and start the calc...

Embodiment 3

[0051] A method of microwave reduction roasting-sulfuric acid leaching of the present embodiment reclaims copper and zinc elements in copper soot, comprising the following steps:

[0052] Step 1. Microwave reduction roasting:

[0053] Copper soot and carbon with 20% of the total amount of copper soot were mixed and ground for 10 minutes, and then put into a microwave oven for carbothermal reduction roasting for 4 hours at a roasting temperature of 600°C.

[0054] Step 2, sulfuric acid leaching of copper and zinc:

[0055] The leaching is carried out in a 500ml three-hole boiler, heated by a water bath, and the water bath is turned on to set a predetermined temperature for preheating. Add it into a three-hole flask, connect an electric stirrer, and when the temperature of the thermocouple reaches the temperature required for the experiment, quickly pour in the weighed copper soot (5g), turn on the stirrer, observe the temperature change of the thermocouple, and start the calcu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com