A kind of beneficiation and smelting method of weak magnetic mineral-encapsulated sulfur-oxygen mixed zinc ore

A weak magnetic, wrapped technology, applied in the field of beneficiation and metallurgy, can solve the problems of difficult leaching of zinc minerals, consumption of leaching agents, etc., to reduce the difficulty of leaching, reduce the amount of ore, and improve the leaching speed and leaching rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: the mass percent content of zinc in the weak magnetic mineral wrapped type sulfur-oxygen mixed zinc ore of the present embodiment is 9.2%, and the oxidation rate of zinc is 70%. The content is 100%, the content of zinc in the weak magnetic minerals is 38%, and the weak magnetic minerals are hematite, limonite and biotite;

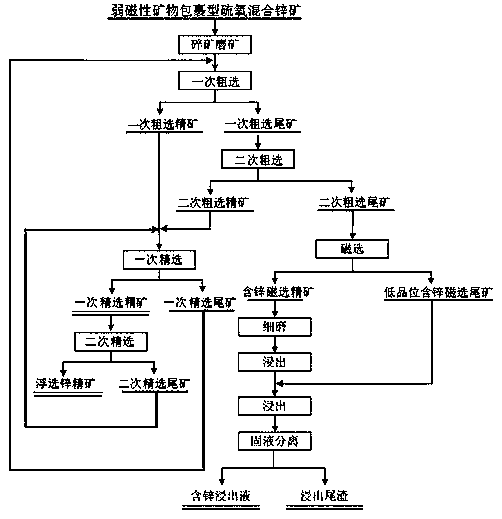

[0023] Such as figure 1 As shown, a method for dressing and smelting weakly magnetic mineral-wrapped sulfur-oxygen mixed zinc ore, the specific steps are as follows:

[0024] (1) Crush and grind the weakly magnetic mineral-encapsulated sulfur-oxygen mixed zinc ore to a mass percentage of -74μm, which accounts for 75% of the mass percentage, and adjust the slurry until the mass percentage concentration of the pulp is 25%. The weak magnetic mineral per ton For the encased sulfur-oxygen mixed zinc ore meter, add 800g vulcanizing agent (the vulcanizing agent is sodium sulfide), 350g activator (the activator is copper sulfate), 400g collect...

Embodiment 2

[0029] Embodiment 2: the mass percent content of zinc in the weak magnetic mineral wrapped type sulfur-oxygen mixed zinc ore of the present embodiment is 13.9%, and the oxidation rate of zinc is 81.5%. The content is 100%, the content of zinc in the weak magnetic minerals is 44%, and the weak magnetic minerals are hematite and limonite;

[0030] Such asfigure 1 As shown, a method for dressing and smelting weakly magnetic mineral-wrapped sulfur-oxygen mixed zinc ore, the specific steps are as follows:

[0031] (1) The weak magnetic mineral-encapsulated sulfur-oxygen mixed zinc ore is crushed and ground to a mass percentage of -74μm, accounting for 80.5%, and the slurry is adjusted to a mass percentage concentration of 32%. The weak magnetic mineral per ton For wrapped sulfur-oxygen mixed zinc ore meter, add 1050g vulcanizing agent (the vulcanizing agent is sodium sulfide), 450g activator (the activator is copper sulfate), 600g collector (the collector is butyl xanthate) and 80g...

Embodiment 3

[0036] Embodiment 3: the mass percent content of zinc in the weak magnetic mineral wrapped type sulfur-oxygen mixed zinc ore of the present embodiment is 18.5%, and the oxidation rate of zinc is 88.5%. The content is 100%, the content of zinc in the weak magnetic minerals is 50%, and the weak magnetic minerals are hematite and limonite;

[0037] Such as figure 1 As shown, a method for dressing and smelting weakly magnetic mineral-wrapped sulfur-oxygen mixed zinc ore, the specific steps are as follows:

[0038] (1) Crushing and grinding the weakly magnetic mineral-encapsulated sulfur-oxygen mixed zinc ore to a mass percentage of -74μm particle size accounted for 85%, and adjusted the slurry to a mass percentage concentration of 38%. The weak magnetic mineral per ton For wrapped sulfur-oxygen mixed zinc ore meter, add 1500g vulcanizing agent (the vulcanizing agent is sodium sulfide), 500g activator (the activator is copper sulfate), 800g collector (the collector is butyl xantha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com